Method for recycling supported hydrogenation catalyst

A hydrogenation catalyst and supported technology, which is applied in the field of recovery and reuse of supported hydrogenation catalysts, can solve problems such as waste, and achieve the effects of reducing production costs, simple recovery methods, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

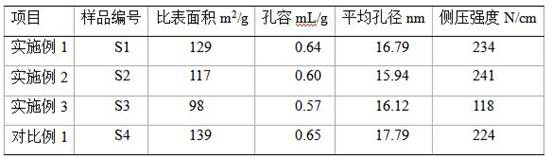

Embodiment 1

[0024] Weigh 204.0 g of macroporous pseudo-boehmite, mix evenly with 15 g of sieved waste catalyst powder, slowly add 5 wt% nitric acid solution during the kneading process, continue kneading for 10 min to peptize, and extrude , to make four-leaf clover strips with a diameter of Φ1.45, let them stand at room temperature for 2 hours, dry in an oven at 120 °C for 2 hours, cool to room temperature and shape them into four-leaf clover strips with a length of 3-5mm, and sieve them through a 20-mesh standard sieve After sieving, it was placed in a muffle furnace, and fired at a rate of 10 °C / min from room temperature to 900 °C for 4 h in a nitrogen atmosphere, and then naturally cooled to room temperature to obtain the blended carrier S1.

[0025] Weigh 18 g of concentrated phosphoric acid (85wt%), dissolve it in 50 g of deionized water, mix it with 34 g of molybdenum oxide and 12 g of basic nickel carbonate, stir and reflux at 90 °C and 300 r / min until completely dissolved, and prep...

Embodiment 2

[0028] Weigh 204.0 g of macroporous pseudo-boehmite, mix evenly with 45 g of sieved waste catalyst powder, slowly add 5 wt% nitric acid solution during the kneading process, continue kneading for 10 min to peptize, and extrude , to make four-leaf clover strips with a diameter of Φ1.45, let them stand at room temperature for 2 hours, dry in an oven at 120 °C for 2 hours, cool to room temperature and shape them into four-leaf clover strips with a length of 3-5mm, and sieve them through a 20-mesh standard sieve After sieving, it was placed in a muffle furnace, and fired at a rate of 10 °C / min from room temperature to 900 °C for 4 h under a nitrogen atmosphere, and then naturally cooled to room temperature to obtain the blended carrier S2.

[0029] Weigh 100 g of blended carrier S2, impregnate an equal volume of impregnating solution A on the carrier according to its water absorption rate, dry at 120 °C for 4 h, and keep the temperature at 200 °C for 4 h under nitrogen atmosphere t...

Embodiment 3

[0031] Weigh 204.0 g of macroporous pseudo-boehmite, mix evenly with 75 g of sieved waste catalyst powder, slowly add 5 wt% nitric acid solution during the kneading process, continue kneading for 10 min to peptize, and extrude , to make four-leaf clover strips with a diameter of Φ1.45, let them stand at room temperature for 2 hours, dry in an oven at 120 °C for 2 hours, cool to room temperature and shape them into four-leaf clover strips with a length of 3-5mm, and sieve them through a 20-mesh standard sieve After sieving, it was placed in a muffle furnace, and was roasted at a rate of 10 °C / min from room temperature to 900 °C for 4 h under a nitrogen atmosphere, and then naturally cooled to room temperature to obtain the blended carrier S3.

[0032] Weigh 100 g of blended carrier S3, impregnate an equal volume of impregnation solution A on the carrier according to its water absorption rate, dry at 120 °C for 4 h, and keep the temperature at 200 °C for 4 h under nitrogen atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com