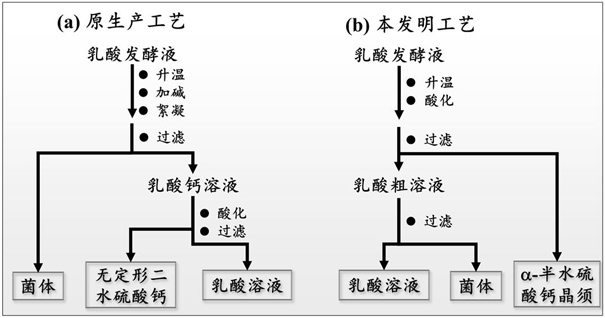

Method for producing alpha-calcium sulfate hemihydrate whiskers and synchronously recovering lactic acid monomers by taking fermentation liquor for producing lactic acid by calcium salt method as raw material

A technology of calcium sulfate hemihydrate and lactic acid monomer, which is applied in the separation/purification of calcium/strontium/barium sulfate, carboxylic acid compounds, organic chemistry, etc. Insufficient green environmental protection and other problems, to achieve the effect of reducing the input of lactic acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

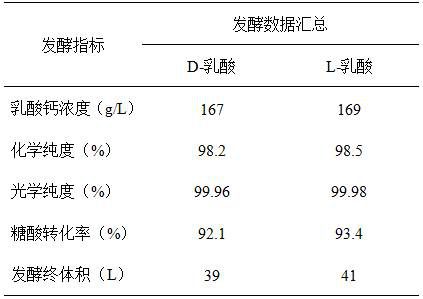

[0032] 1. Preparation of lactic acid fermentation broth by calcium salt method

[0033] The preparation of calcium salt method lactic acid fermentation liquid is carried out according to the method of the previous invention authorized patent (Wang Zhengxiang et al., ZL201580000781.7). The fermentation strain is CGMCC 11059 or CGMCC11060, and the strain CGMCC 11059 is used for the fermentation production of D-lactic acid. CGMCC11060 is used for the fermentative production of L-lactic acid (Wang Zhengxiang et al., ZL201580000781.7). In the initial stage of fermentation, add glucose to the basic fermentation medium to a final concentration of 10-50 g / L, culture at 30°C-37°C, pH 5.5-7.5, ventilation 0.1-2.0 vvm, 100-1000 r / min stirring The culture time is 5-15 h, and the bacterial volume reaches 10-50OD; close the ventilation, reduce the stirring speed to 0-300 r / min, increase the fermentation temperature to 37°C-50°C, and add a final concentration of 16%-25 % glucose solution, t...

Embodiment 1

[0048] Embodiment 1: the preparation of lactic acid fermentation broth

[0049]Inoculate the glycerol tube frozen storage of D-lactic acid-producing strain CGMCC 11059 or L-lactic acid-producing strain CGMCC 11060 into 50 mL of LB liquid medium, and culture it on a shaker at 37°C and 200 r / min for 12 h. First-class seed liquid. The primary seed solution was inoculated in 150 mL of M9 liquid medium with glucose as the carbon source, the initial sugar concentration was 0.5%, and cultured on a shaker at 37°C and 200 r / min for 10 h as the secondary seed solution. The secondary seed liquid was inoculated into a fermenter containing M9 liquid medium according to the inoculation amount of the initial OD value of 0.3. After inoculation, the initial volume of the 50 L fermenter was 25 L, and the initial addition of invert syrup was 3%. Body fermentation production. The initial temperature of the fermentation was controlled at 37°C, and the pH was maintained at 6.5 with ammonia water....

Embodiment 2

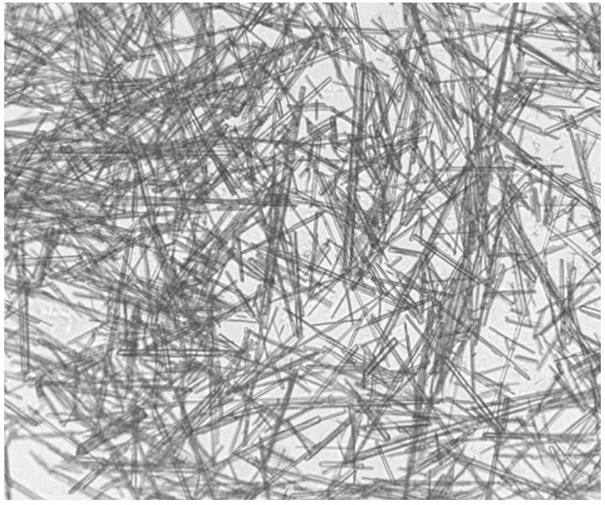

[0052] Embodiment 2: the preparation of α-calcium sulfate hemihydrate whisker

[0053] The lactic acid fermentation liquid obtained in the above-mentioned Example 1 was heated to 88° C. in the reactor and maintained at this temperature, and 5 mol / L sulfuric acid solution was added under stirring at 20 r / min. The total amount of sulfuric acid was controlled so that the molar ratio of lactic acid to sulfuric acid was 1:0.5, the time limit for adding all the sulfuric acid solution is controlled at 1 h / ton of fermentation broth; after adding all the sulfuric acid solution, keep the reaction for 15 min; The collected solid part is the α-calcium sulfate hemihydrate whisker, and the obtained α-calcium sulfate hemihydrate whisker is washed with absolute ethanol and flash-dried by steam at 120°C, and it is α-calcium sulfate hemihydrate crystal The finished product; the collected liquid part is the free lactic acid liquid containing lactic acid monomer, which is filtered through a plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com