Novel Fenton oxidation method industrial wastewater treatment process

A technology of Fenton oxidation and industrial wastewater, which is applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sewage treatment, etc. It can solve the problems of little application value, Fenton reaction Fenton agent dosage increase, and increase investment and other issues, to achieve the effect of improving utilization efficiency, reducing sludge production, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

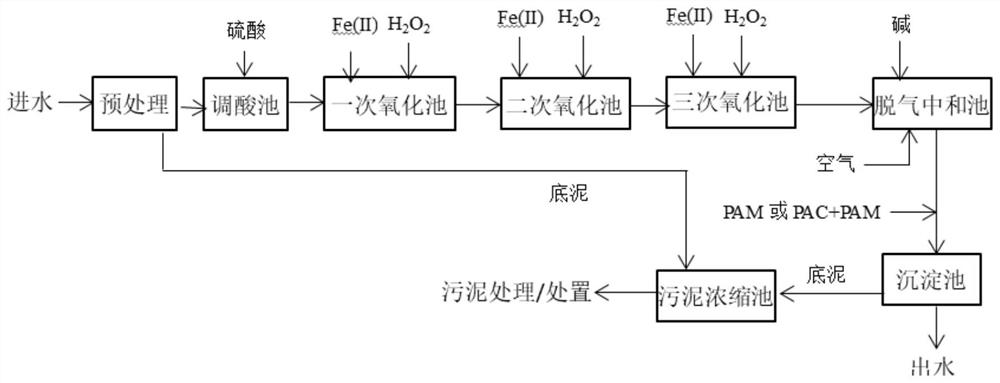

Embodiment 1

[0097] After biochemical treatment of a certain chemical wastewater, the effluent COD is 1200mg / L, and the remaining COD is difficult to degrade further. Therefore, Fenton oxidation advanced treatment is adopted. The treatment process using the traditional Fenton is as follows: adjust the pH value of the wastewater to 6.0, add ferrous sulfate (heptahydrate) 2600mg / L, hydrogen peroxide (mass concentration 30%, the same below) 1400mg / L to a single oxidation tank, and the residence time is 80min . The Fenton treatment method invented by the invention is as follows: after pretreatment to remove part of SS, the pH value of the wastewater is adjusted to 6.0, and then enters two oxidation pools, namely the primary oxidation pool and the secondary oxidation pool, and the primary oxidation pool passes through the pipeline mixer. Add ferrous sulfate 1300mg / L and hydrogen peroxide 700mg / L successively for oxidation and precipitation, and the residence time is 40min; the secondary oxidati...

Embodiment 2

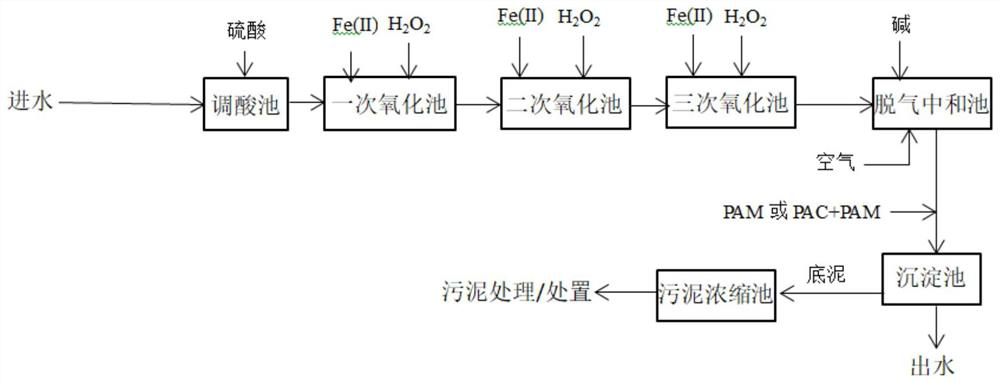

[0101] A pharmaceutical wastewater is pretreated by Fenton oxidation to improve its biodegradability and reduce its biological toxicity. The treatment process using the traditional Fenton is: adjust the pH value of the wastewater to 5.0, add 1000 mg / L of ferrous sulfate (heptahydrate, the same below) in a single oxidation tank, and add 800 mg of hydrogen peroxide (mass concentration is 27.5%, the same below) / L, residence time 60min. Adopting the Fenton treatment method of the present invention is: after the wastewater pH value is adjusted to 5.0, it enters three oxidation ponds successively, and the dosage of ferrous sulfate and hydrogen peroxide in each oxidation pond is the same (the total dosage is consistent with traditional Fenton), The residence time of wastewater in each oxidation tank is 15min, 15min, and 30min respectively. The process flow chart is as follows: figure 1 shown. The results of the two Fenton treatment methods are shown in Table 2 below. Under the sam...

Embodiment 3

[0105] The biochemical effluent of landfill leachate contains high refractory COD, and it is difficult to achieve discharge standards. Fenton oxidation is used for advanced treatment. The waste water has a small flow rate and is processed in batches. The treatment process using the traditional Fenton is: adjust the pH value of the wastewater to 5.0, add ferrous sulfate (heptahydrate, the same below) 2500mg / L at one time, and add hydrogen peroxide (mass concentration of 30%, the same below) 1300mg / L , react for 90min. The Fenton treatment method of the present invention is as follows: in the single oxidation tank, the pH value of the wastewater is first adjusted to 5.0, and then at 0min, 30min, and 60min, ferrous sulfate and hydrogen peroxide are added in equal amounts respectively (total dosage is the same as that of traditional Fenton). Dayton consistent), the process flow chart is as follows figure 2 shown. The results of the two Fenton treatment methods are shown in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com