Undoped organic small molecule hole transport material, perovskite solar cell and preparation method and application thereof

A technology of solar cells and hole transport layers, applied in organic chemistry, circuits, photovoltaic power generation, etc., can solve the problems of affecting the photoelectric conversion efficiency of devices, poor film forming ability, and limiting the open circuit voltage of devices, so as to promote large-scale commercialization Production, avoiding unstable factors, improving the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

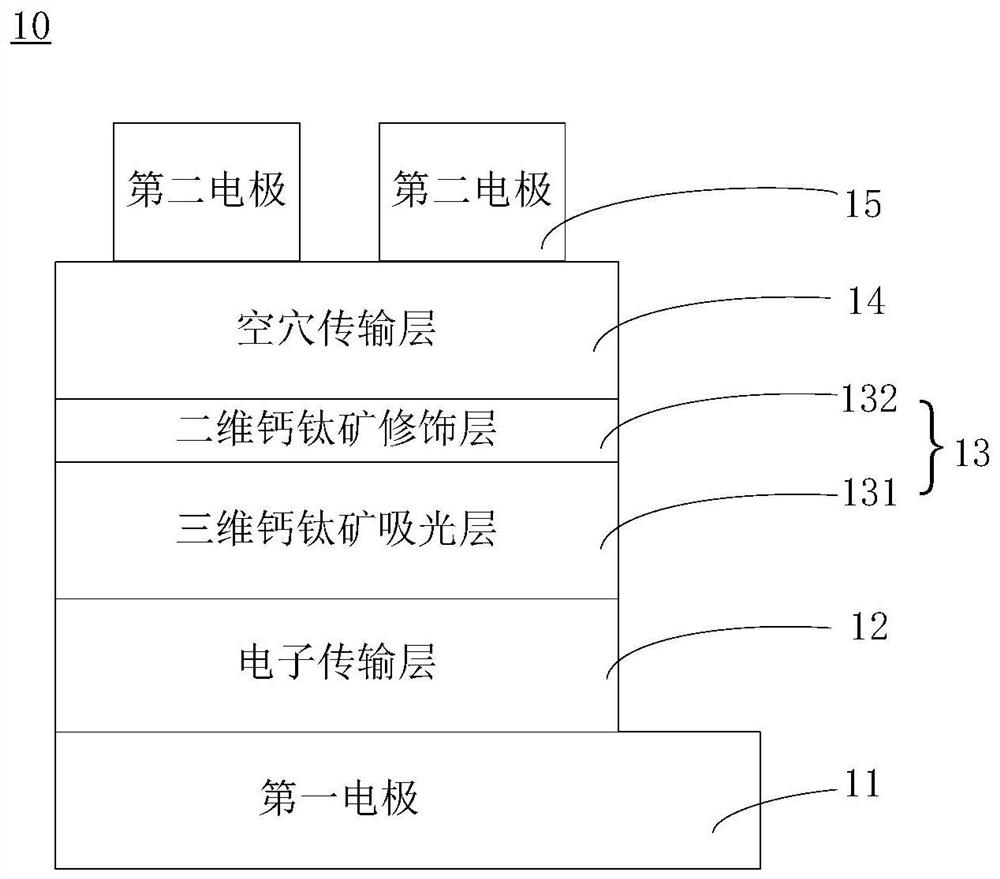

[0070] The present invention also provides a preparation method of the perovskite solar cell 10, comprising the following steps:

[0071] On the first electrode 11, an electron transport layer 12, a perovskite light absorption layer 13, a hole transport layer 14 and a second electrode 15 are formed in this order.

[0072] Preparation of the first electrode 11 : the transparent oxide semiconductor is washed with an inorganic solvent and a first organic solvent respectively, dried, and then subjected to ultraviolet ozone treatment to obtain the substrate of the first electrode 11 .

[0073] The above-mentioned inorganic solvent is deionized water, and the first organic solvent is selected from at least one of acetone, ethanol and isopropanol. Specifically, the first organic solvent is ethanol, and the cleaning effect is better.

[0074] Further, in order to achieve a better cleaning effect, the transparent oxide semiconductor can also be cleaned with detergent before cleaning with...

Embodiment 1

[0089] This embodiment provides an undoped organic small molecule hole transport material shown in formula II, and the specific preparation process is as follows:

[0090] Step S1: in a nitrogen atmosphere, put 0.15g of 0.276g and 20 mg of Pd (PPh 3 ) 4 It was put into a three-necked flask, and then 25 mL of toluene was added to obtain a mixed solution.

[0091] Step S2: Heat the above mixed solution to 110°C, stir for 8 hours, pour the obtained mixture into water and extract with chloroform, and use anhydrous MgSO for the obtained organic layer 4 Drying gave crude product. The crude product was purified by silica gel chromatography, wherein the eluent of the silica gel column was chloroform and n-hexane in a volume ratio of 1:1 to obtain a red solid.

[0092] Step S3: Combine the above red solid with 0.5g of Trichloromethane and 4 mL of piperidine were added to dissolve, and then degassed with nitrogen 5 times to obtain a mixture.

[0093] Step S4: The above mixture...

Embodiment 2

[0095] This embodiment provides an undoped organic small molecule hole transport material as shown in formula III, and the specific preparation process is as follows:

[0096] Step S1: in a nitrogen atmosphere, put 0.15g of 0.276g and 20 mg of Pd (PPh 3 ) 4 It was put into a three-necked flask, and then 25 mL of toluene was added to obtain a mixed solution.

[0097] Step S2: heating the above mixed solution at 110°C, stirring for 8 hours, pouring the obtained mixture into water and extracting with chloroform, and using anhydrous MgSO for the obtained organic layer 4 Drying gave crude product. The crude product was purified by silica gel chromatography, wherein the eluent of the silica gel column was chloroform and n-hexane in a volume ratio of 1:1 to obtain a red solid.

[0098] Step S3: put 0.5 g of the above red solid Trichloromethane and 4 mL of piperidine were added to dissolve, and then degassed with nitrogen 5 times to obtain a mixture.

[0099] Step S4: The ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com