Method for preparing theaflavin by enzyme catalysis and product prepared by method

A technology for catalytic preparation and theaflavin, applied in the field of tea processing, can solve the problems of high cost of immobilized enzymes, changes in the expression of steric phase activity, etc., and achieve the effects of high activity and content of theaflavin, little impact, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

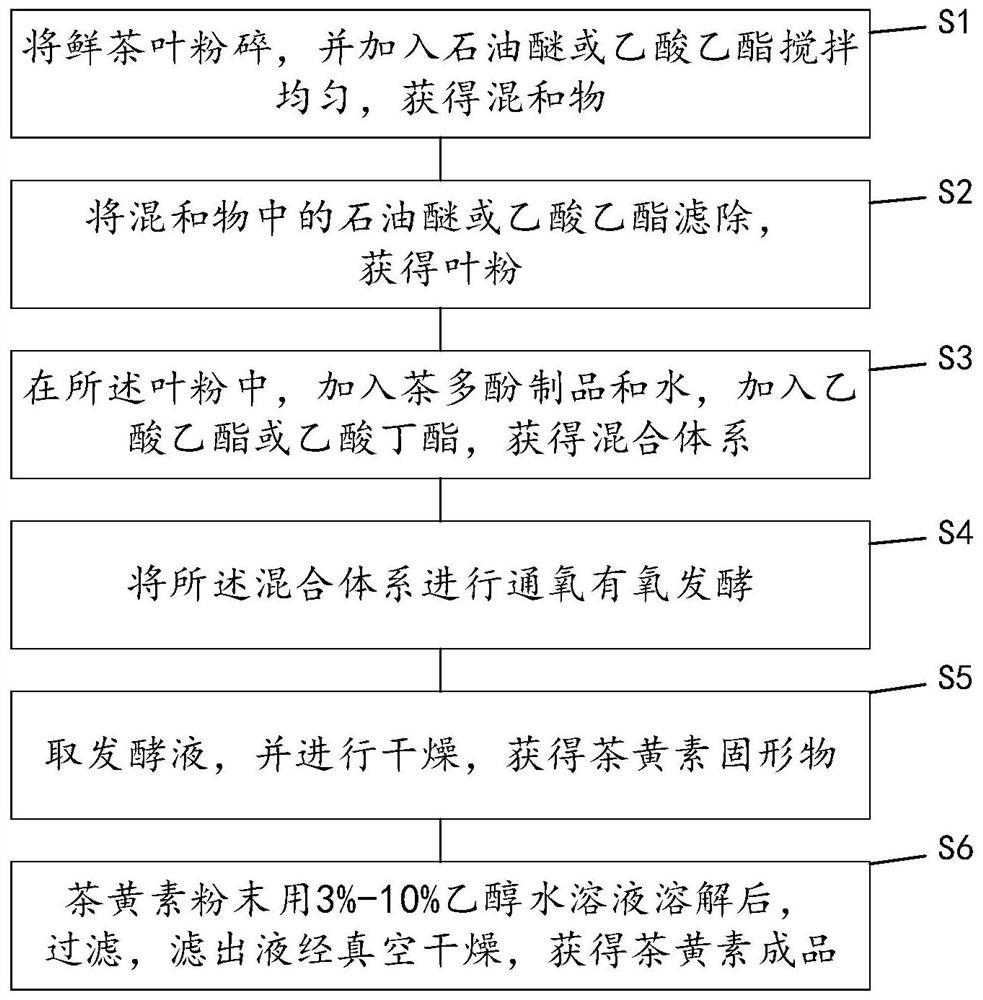

[0092] Preparation of leaf powder: 100 kilograms of freshly plucked fresh tea leaves (picked in August in Mashan, Wuxi, Jiangsu), shredded and crushed after withering, put into a temperature-controlled stainless steel extraction kettle with a sieve plate at the bottom and a side filter outlet, and added 800 liter of petroleum ether, stirred at room temperature for 60 minutes, filtered off the dark green petroleum ether solution and recovered petroleum ether.

[0093] Aerobic fermentation: continue to add 700 liters of ethyl acetate, 20 kg of green tea water extract with a tea polyphenol content of 35% and 15 liters of water into the extraction kettle, blow in oxygen at room temperature or 0°C-20°C and stir for fermentation. And detect the absorbance change of fermented liquid at 380 nanometers place with ultraviolet spectrophotometer, treat that the A380 absorbance of fermented liquid reaches peak value and begin to walk usually stop fermentation, filter and obtain leaf residue...

Embodiment 2

[0104] Preparation of leaf powder: 100 kilograms of freshly plucked fresh tea leaves (picked in August in Mashan, Wuxi, Jiangsu), shredded and crushed after withering, put into a stainless steel extraction kettle with a sieve plate at the bottom and a side filter outlet, and added 800 liters of Petroleum ether, stirred at room temperature for 60 minutes, filtered off the dark green petroleum ether solution and recovered petroleum ether.

[0105] Aerobic fermentation: continue to add 600 liters of ethyl acetate, 10 kg of low-caffeine green tea extract containing 85% tea polyphenols (caffeine content is less than 1%) and 8 liters of water in the extraction kettle, and blow it in at room temperature or low temperature Oxygen is stirred and fermented, and the absorbance change of the fermented liquid at 380 nanometers is detected by a UV spectrophotometer. When the A380 absorbance of the fermented liquid reaches a peak and starts to walk, the fermentation is stopped, and the orange...

Embodiment 3

[0117] Preparation of leaf powder: 100 kg of freshly plucked fresh tea leaves (picked in August in Mashan, Wuxi, Jiangsu), withered, chopped and pulverized, put into a stainless steel extraction kettle with a sieve plate at the bottom and a side filter outlet, and then added 100 kg Extract green tea powder as the raw material of tea polyphenols, add 800 kg of petroleum ether and 100 kg of water, stir at room temperature for 60 minutes, filter out the dark green petroleum ether solution and recover the petroleum ether. Add 800 liters of sherwood oil again in the extraction kettle, stir at room temperature for 60 minutes, filter off the light green sherwood oil solution and reclaim sherwood oil.

[0118] Aerobic fermentation: continue to add 800 kg of ethyl acetate to the extraction kettle, blow in oxygen at room temperature or at a low temperature of 0°C-20°C and stir for fermentation, and use a UV spectrophotometer to detect the change in the absorbance of the fermentation brot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com