Flexible zinc-air battery gel electrolyte as well as preparation method and application thereof

A gel electrolyte, air battery technology, applied in electrolytes, solid electrolytes, non-aqueous electrolytes, etc., can solve the problems of failing to meet the requirements of wearable electronic products, destroying polymers, and degrading the mechanical properties of gels. Glue ion conductivity, good hydrophilicity, and the effect of improving adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

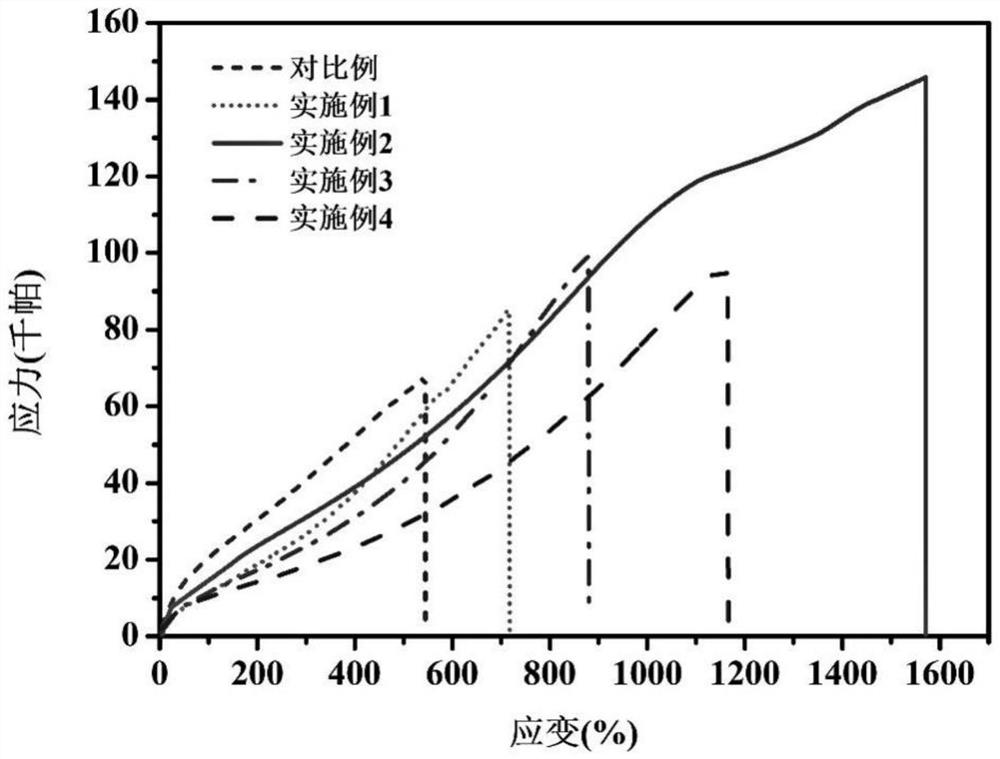

Embodiment 1

[0037] A preparation method of the flexible zinc-air battery gel electrolyte of the present invention comprises the following steps:

[0038] (1) After adding 1.5 g of acrylic acid into 2.0 g of ultrapure water and fully stirring, slowly add 0.8 g of sodium hydroxide with a concentration of 20 mol / L dropwise in an ice bath, and vigorously stir and mix.

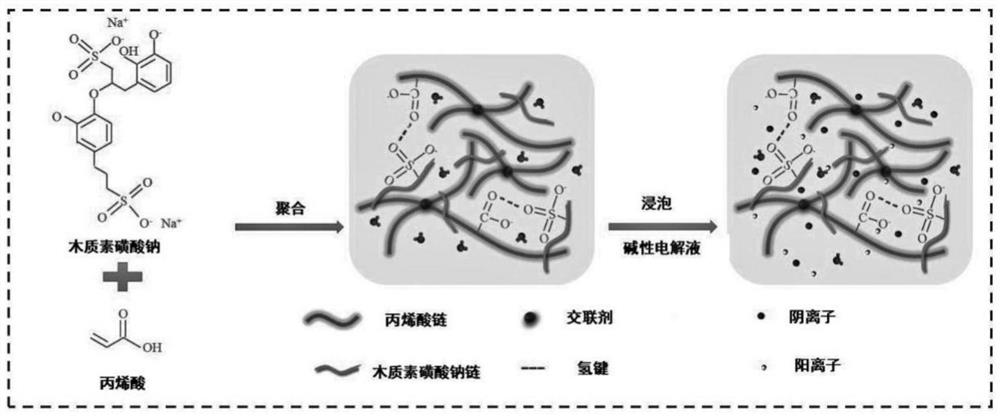

[0039] (2) Add 0.01g of sodium lignosulfonate, 0.002g of N,N'-methylenebisacrylamide and 0.02g of potassium persulfate to the above solution in sequence, stir for 30min and then ultrasonically remove the foam.

[0040] (3) The above mixed solution was poured into a glass mold with a 2 mm thick silica gel pad, sealed and placed in a blast oven at 60° C. for 3 hours to obtain a polymer gel film.

[0041] (4) Soak the prepared polymer gel film in 20 mL of strong alkaline electrolyte containing 6 mol / L potassium hydroxide and 0.2 mol / L zinc acetate for 24 hours to obtain a polymer gel electrolyte with high ionic conductivity.

[...

Embodiment 2

[0044] A preparation method of the flexible zinc-air battery gel electrolyte of the present invention comprises the following steps:

[0045] (1) After adding 1.5 g of acrylic acid into 2.0 g of ultrapure water and fully stirring, slowly add 0.8 g of sodium hydroxide with a concentration of 20 mol / L dropwise in an ice bath, and vigorously stir and mix.

[0046] (2) Add 0.02g sodium lignosulfonate, 0.002g N,N'-methylenebisacrylamide and 0.02g potassium persulfate to the above solution in sequence, stir for 30min and then ultrasonically remove the foam.

[0047] (3) The above mixed solution was poured into a glass mold with a 2 mm thick silica gel pad, sealed and placed in a blast oven at 60° C. for 3 hours to obtain a polymer gel film.

[0048](4) Soak the worthwhile polymer gel film in 20 mL of strong alkaline electrolyte containing 6 mol / L potassium hydroxide and 0.2 mol / L zinc acetate for 24 hours to obtain a polymer gel electrolyte with high ionic conductivity.

[0049] Th...

Embodiment 3

[0051] A preparation method of the flexible zinc-air battery gel electrolyte of the present invention comprises the following steps:

[0052] (1) After adding 1.5 g of acrylic acid into 2.0 g of ultrapure water and fully stirring, slowly add 0.8 g of sodium hydroxide with a concentration of 20 mol / L dropwise in an ice bath, and vigorously stir and mix.

[0053] (2) Add 0.03g of sodium lignosulfonate, 0.002g of N,N'-methylenebisacrylamide and 0.02g of potassium persulfate to the above solution in sequence, stir for 30min and then ultrasonically remove the foam.

[0054] (3) The above mixed solution was poured into a glass mold with a 2 mm thick silica gel pad, sealed and placed in a blast oven at 60° C. for 3 hours to obtain a polymer gel film.

[0055] (4) Soak the prepared polymer gel film in 20 mL of strong alkaline electrolyte containing 6 mol / L potassium hydroxide and 0.2 mol / L zinc acetate for 24 hours to obtain a polymer gel electrolyte with high ionic conductivity.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com