Colored fluorescent diatom ooze and preparation method thereof

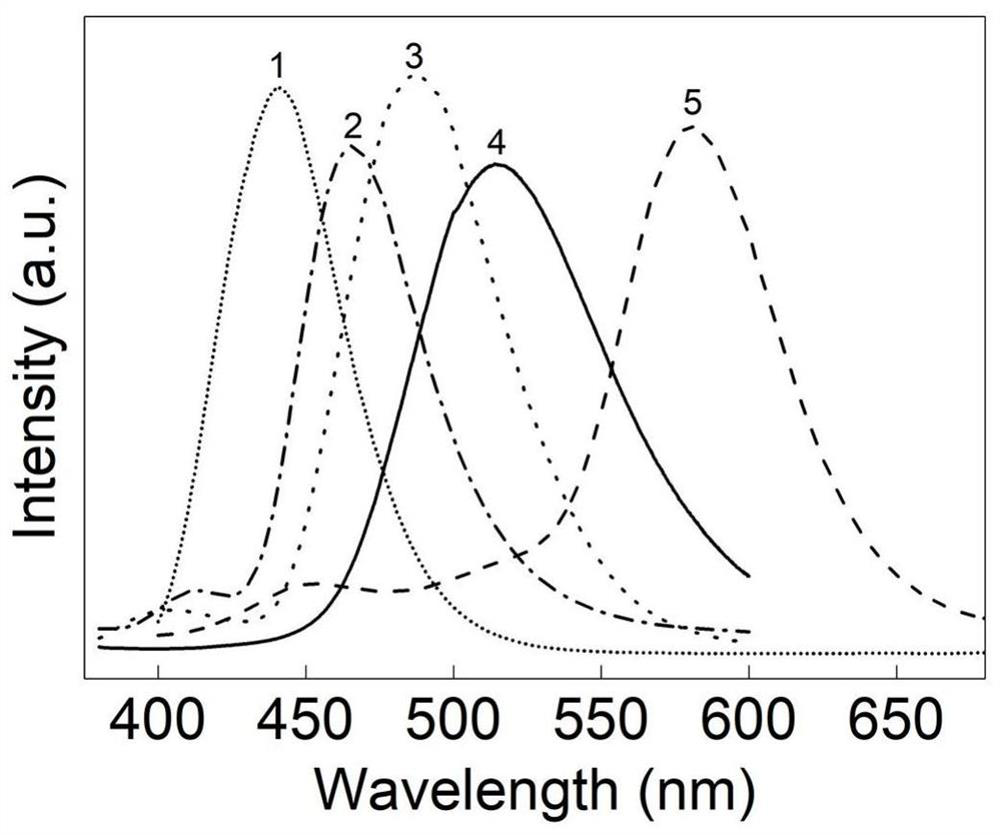

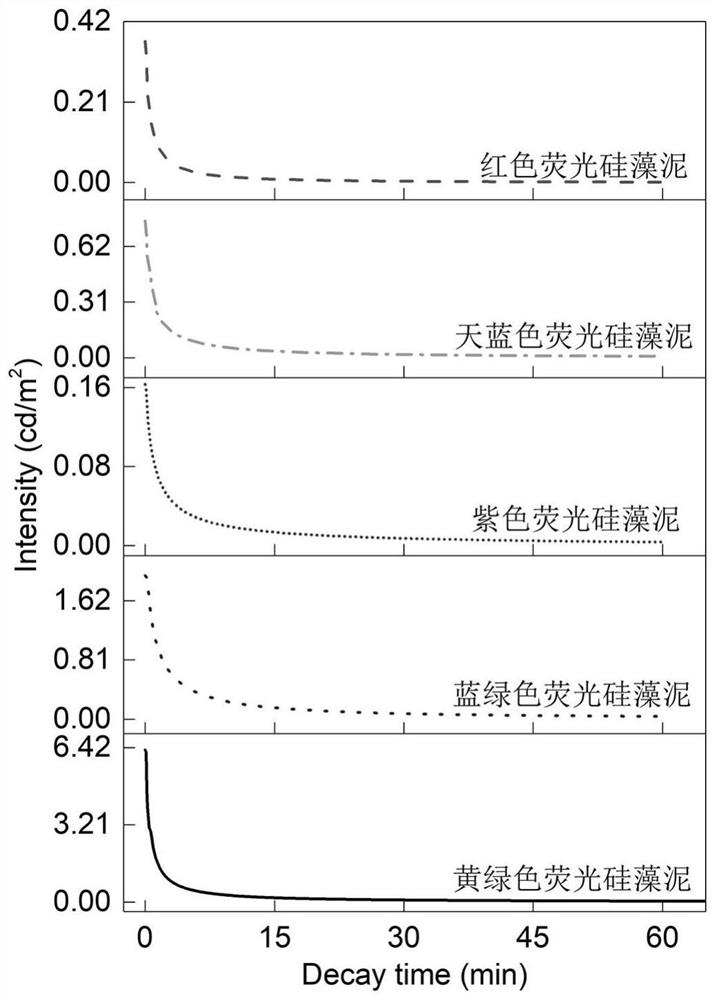

A diatom mud and fluorescent technology, applied in the field of wall decoration materials, can solve the problems of losing the indication function, the trapped people cannot identify the evacuation direction in time, and reduce the escape efficiency of personnel, so as to achieve long afterglow life and perfect wall decoration Decoration effect, luminous color rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

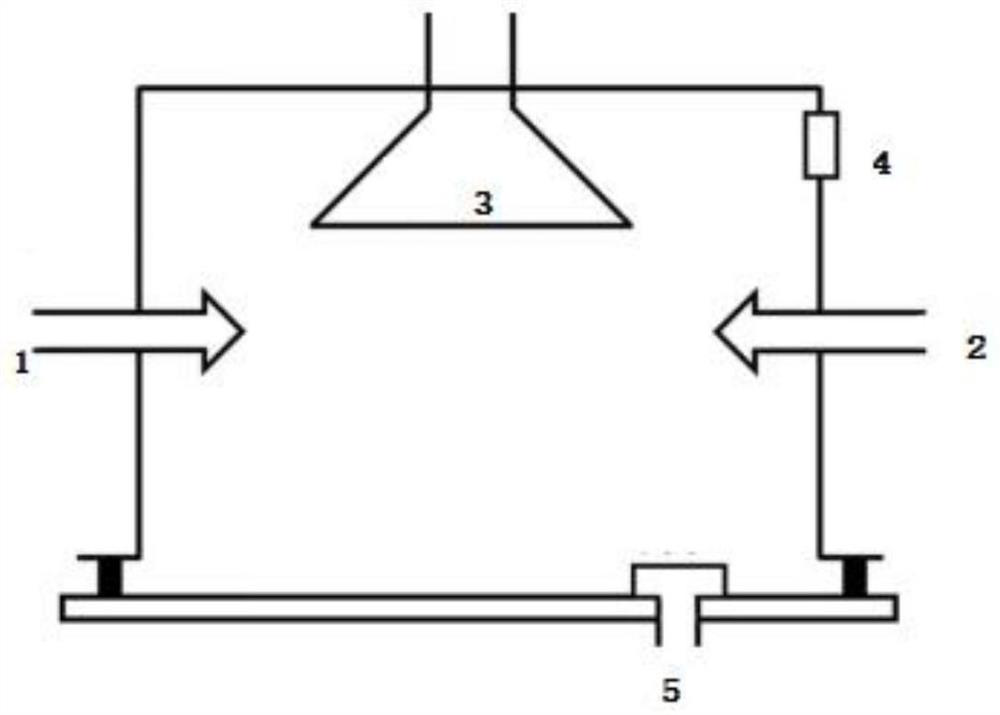

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of colored fluorescent diatom mud

[0030] Specifically include the following steps:

[0031] Step 1. Diatomite, high viscosity attapulgite, kaolin, light calcium, rutile titanium dioxide, silicone modified acrylic resin, polyvinyl alcohol, hydroxypropyl methylcellulose, white cement and titanate couple The coupling agent was dried in a blast oven at 80°C to remove the surface adsorbed water.

[0032] Step 2. According to the mass ratio, weigh 30 parts of diatomite, 6 parts of high-viscosity attapulgite, 6 parts of kaolin, 8 parts of 800 mesh light calcium, 12 parts of rutile titanium dioxide, and 10 parts of silicone-modified acrylic resin , 6 parts of polyvinyl alcohol, 4 parts of hydroxypropyl methylcellulose, 3 parts of white cement, 3 parts of titanate coupling agent, SrAl 2 o 4 ; Eu, Dy 20 parts. Among them, SrAl 2 o 4 : Eu, Dy have been coated with inorganic substances. In addition, 40 parts of anionic surfactant dialkyl sulfosuccina...

Embodiment 2

[0039] Example 2: Preparation of colored fluorescent diatom mud

[0040] Specifically include the following steps:

[0041] Step 1. The raw materials diatomite, high viscosity attapulgite, kaolin, light calcium, rutile titanium dioxide, silicone modified acrylic resin, polyvinyl alcohol, hydroxypropyl methylcellulose, white cement and titanate The coupling agent was dried in a blast oven at 70°C to remove the water adsorbed on the surface.

[0042] Step 2. According to the mass ratio, weigh 40 parts of diatomite, 8 parts of high-viscosity attapulgite, 8 parts of kaolin, 10 parts of 1250 mesh light calcium, 12 parts of rutile titanium dioxide, and 12 parts of silicone modified acrylic resin , 8 parts of polyvinyl alcohol, 5 parts of hydroxypropyl methylcellulose, 5 parts of white cement, 5 parts of titanate coupling agent, Sr 4 Al 14 o 25 : Eu, Dy 25 parts. In addition, 45 parts of anionic surfactant N-octadecyl sulfosuccinamide disodium salt are included.

[0043] Step 3...

Embodiment 3

[0046] Example 3: Preparation of colored fluorescent diatom mud

[0047] Specifically include the following steps:

[0048] Step 1. The raw materials diatomite, high viscosity attapulgite, kaolin, light calcium, rutile titanium dioxide, silicone modified acrylic resin, polyvinyl alcohol, hydroxypropyl methylcellulose, white cement and titanate The coupling agent was dried in a blast oven at 70°C to remove the water adsorbed on the surface.

[0049] Step 2. According to the mass ratio, weigh 35 parts of diatomite, 10 parts of high-viscosity attapulgite, 8 parts of kaolin, 12 parts of 1250 mesh light calcium, 15 parts of rutile titanium dioxide, and 12 parts of silicone modified acrylic resin , 8 parts of polyvinyl alcohol, 4 parts of hydroxypropyl methylcellulose, 5 parts of white cement, 5 parts of titanate coupling agent, Sr 2 MgSi 2 o 7 : 35 parts of Eu, Dy, and 40 parts of anionic surfactant dicyclohexyl sulfosuccinate sodium salt.

[0050] Step 3. The mixture obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com