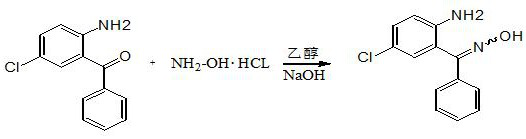

Preparation method of 2-amino-5-chlorobenzophenone oxime

A technology of benzophenone oxime and chlorobenzophenone is applied in the directions of oxime preparation, organic chemistry, etc., can solve the problems of easy punching, cumbersome post-processing operation, low total reaction yield and the like, and achieves short reaction time, The reaction process is easy to control, and the reaction process has no side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of 2-amino-5 chloro-benzophenone oxime, comprising the following steps

[0033] (1) Selection of raw materials: select ethanol 3450ml, 2-amino-5-chlorobenzophenone 490g, hydroxylamine hydrochloride 185g, NaOH 200g, quantitative acetic acid and water;

[0034] (2) Reaction: Put 3450ml of ethanol into a 5L reaction bottle, start stirring, then put in 490g of 2-amino-5-chlorobenzophenone, 185g of hydroxylamine hydrochloride and 200g of NaOH, put the bottle cap on, seal the feeding port, and heat up After treatment, add activated carbon and reflux for 3 hours to obtain the reactant 2-amino-5-chloro-benzophenone oxime. The molar ratio of sodium oxide is 1.0:2.0, and the volume ratio of aminoketone weight to ethanol is 1.0:5.0;

[0035] (3) Distillation: After step (2), add 1kg of water to the reaction bottle, continue heating to distill out ethanol, when the ethanol is no longer distilled, add 2kg of water to the reaction bottle, stir for 25min, at this...

Embodiment 2

[0041] A preparation method of 2-amino-5 chloro-benzophenone oxime, comprising the following steps

[0042] (1) Selection of raw materials: select ethanol 3550ml, 2-amino-5-chlorobenzophenone 510g, hydroxylamine hydrochloride 190g, NaOH 205g, quantitative acetic acid and water;

[0043] (2) Reaction: Put 3550ml of ethanol into a 5L reaction bottle, start stirring, then put in 510g of 2-amino-5-chlorobenzophenone, 190g of hydroxylamine hydrochloride and 205g of NaOH, put the bottle cap on, seal the feeding port, and heat up After treatment, add activated carbon and reflux for 3 hours to obtain the reactant 2-amino-5 chloro-benzophenone oxime. The molar ratio of sodium oxide is 1.0:2.2, and the volume ratio of aminoketone weight to ethanol is 1.0:6.0;

[0044] (3) Distillation: After step (2), add 1kg of water to the reaction bottle, continue heating to distill out ethanol, when the ethanol is no longer distilled, add 2kg of water to the reaction bottle, stir for 35min, at this...

Embodiment 3

[0050] A preparation method of 2-amino-5 chloro-benzophenone oxime, comprising the following steps

[0051](1) Selection of raw materials: select ethanol 3600ml, 2-amino-5-chlorobenzophenone 515g, hydroxylamine hydrochloride 200g, NaOH 215g, quantitative acetic acid and water;

[0052] (2) Reaction: Put 3600ml of ethanol into a 5L reaction bottle, start stirring, then put in 515g of 2-amino-5-chlorobenzophenone, 200g of hydroxylamine hydrochloride and 215g of NaOH, put the bottle cap on, seal the feeding port, and heat up After treatment, add activated carbon to reflux for 3 hours to obtain the reactant aminoketone, the temperature of the reaction system is 70°C, the molar ratio of aminoketone to hydroxylamine hydrochloride is 1.0:1.5, the molar ratio of aminoketone to sodium hydroxide is 1.0:2.8, The volume ratio of aminoketone weight to ethanol is 1.0:8.0;

[0053] (3) Distillation: After step (2), add 1kg of water to the reaction bottle, continue heating to distill ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com