Strain combination for producing sclareol, application and method for producing sclareol

A technology of sclareol and sclareol, which is applied in the field of synthetic biology, can solve the problems of long growth cycle of sclare, influence on aroma characteristics, and great influence of environmental factors, so as to promote the production of sclareol by yeast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

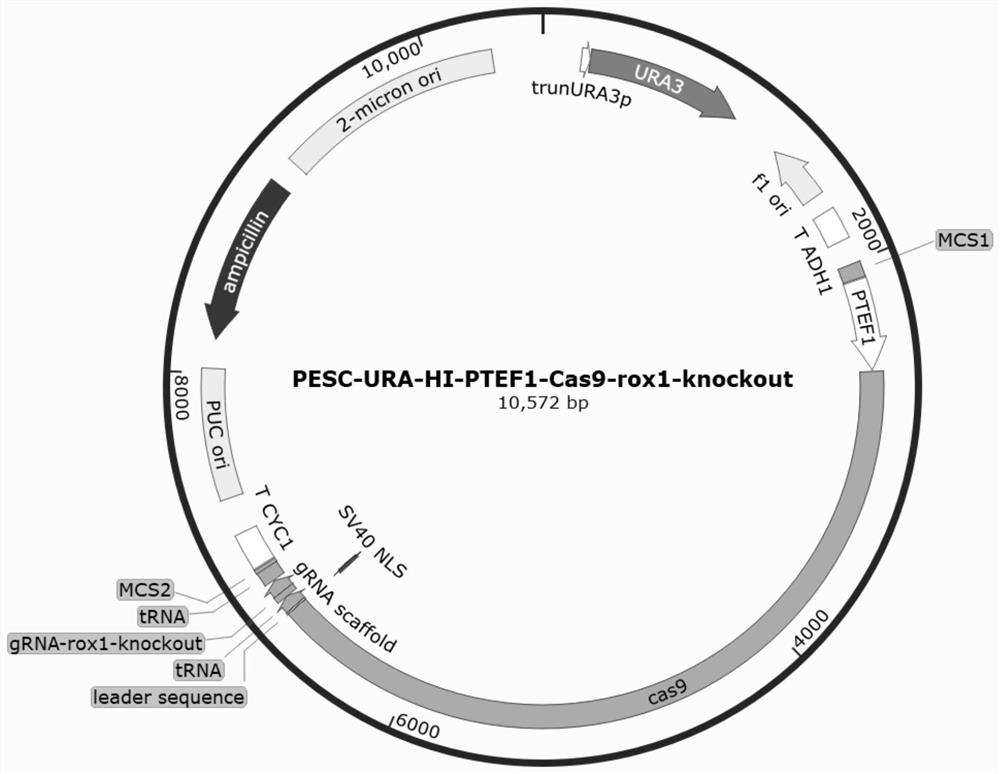

[0024] Example 1: Construction of Sclareol-producing Saccharomyces cerevisiae strain

[0025] Using codon optimization software, the codons of lysandene diol pyrophosphate synthase (GenBank No.: JN133923.1) and sclareol synthase (GenBank No.: JN133922) from Salvia miltiorrhiza were codified with Saccharomyces cerevisiae as the host sub-optimization, and artificially synthesize the optimized sequence. The genes were truncated through the signal peptide online prediction website, namely OtSsLPPs3 and OtSsTPs1132. Use the following primers:

[0026] OtTpsSa3-BamHI-F: GGATCCATGGCTTCACAAGCATCAGAAAA;

[0027] OtTpsSa3-XhoI-R: CTCGAGTTAAACAACTGGTCTAAACAAAACT;

[0028] OtSsTps1132-EcoRI-F:GAATTCATGATGGCTAAAATGAAAGAAAATTT;

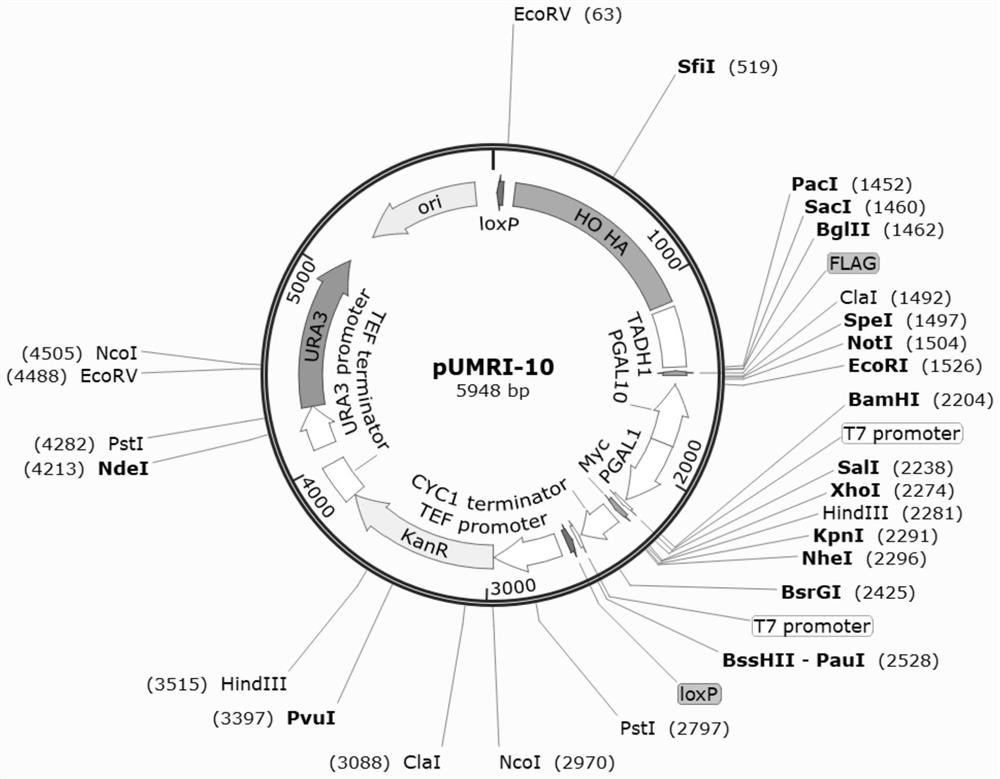

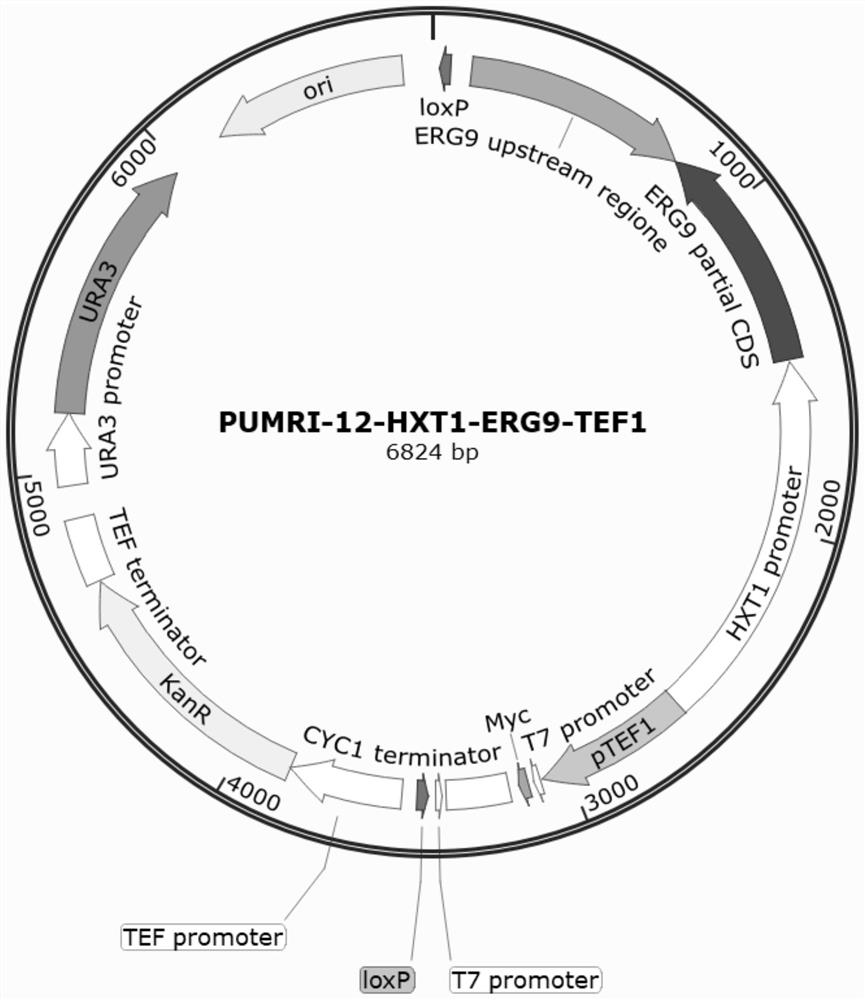

[0029] OtSsTps1132-SpeI-R: ACTAGTTTAAAAAAAAAAAGATTTCATATCTTCT, the optimized truncated OtSsLPPs3 (nucleotide sequence such as SEQ ID NO.1) and OtSsTPs1132 (nucleotide sequence such as SEQ ID NO.2) were cloned into the yeast integrative plasmid pUMRI-10 ( figu...

Embodiment 2

[0041] Embodiment 2: the method that fungus ATCC 20624 is cultivated alone to produce sclareol:

[0042] The first step: the fungal ATCC 20624 seed liquid expansion culture. Pick a single colony of the fungus ATCC 20624 from the YPD plate and insert it into a 100 mL shake flask containing 20 mL of YPD. Cultivate for 48 hours at 25° C. on a shaker with a rotational speed of 180 rpm to obtain fungal ATCC20624 seed liquid.

[0043] The second step: the fungus ATCC 20624 was inoculated into 50 mL of YPD medium with a 4% (v / v) inoculum amount, and 0.2 g / L sclareol was added at the same time. Incubate at 25° C. for 72 h on a shaker with a rotational speed of 180 rpm.

[0044] Step 3: After the cultivation, take 1 mL of fermentation broth, add an equal volume of ethyl acetate, vortex, and sonicate in an ultrasonic cleaner for 10 minutes to thoroughly extract the sclarediol in the fermentation broth. After sonication, centrifuge at 12000×g for 5 min to take 500 μL of organic phase,...

Embodiment 3

[0045] Example 3: Establishment of co-cultivation system of Saccharomyces cerevisiae genetic engineering strain and fungus ATCC 20624

[0046] The first step: YN02 strain seed liquid expansion culture. A single colony of Saccharomyces cerevisiae producing sclareol was picked from the YPD plate and inserted into a test tube containing 5 mL of YPD liquid, and cultured at 30° C. for 12 hours on a shaker with a rotation speed of 220 rpm to obtain yeast seed liquid.

[0047] The second step: fungal ATCC 20624 seed liquid expansion culture. Pick a single colony of the fungus ATCC 20624 from the YPD plate and insert it into a 100 mL shake flask containing 20 mL of YPD. Cultivate at 24° C. for 48 hours on a shaker with a rotating speed of 180 rpm to obtain fungal ATCC20624 seed liquid.

[0048] Step 3: S. cerevisiae at initial OD 600 The seed solution was inoculated into 50 mL of YPD fermentation medium with an inoculation amount of 0.05, and cultured on a shaker at 30° C. with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com