Method for removing high-concentration chloride ions in water by using modified fly ash

A fly ash, high-concentration technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the cost of easy oxidation of cuprous ions, high requirements for equipment corrosion resistance, and expensive silver ions and other problems, to achieve good physical and chemical adsorption, enhance anti-interference ability, and remove a wide range of pollution factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

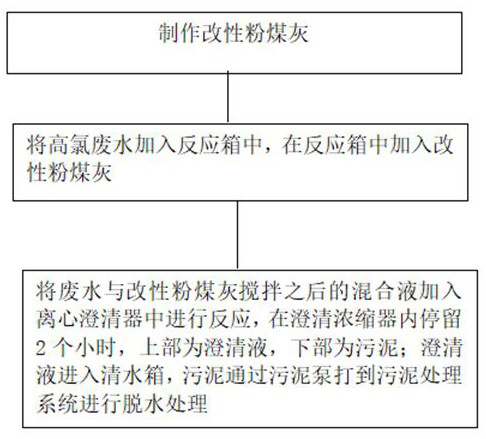

[0033] Such as figure 1 Shown, a kind of method utilizing modified fly ash to remove high concentration chloride ion in water comprises the following specific steps:

[0034] Step 1: Add 100 parts of fly ash to a ball mill for pulverization and ball milling and sieving, the ball milling time is 45 minutes, and the sieving is to pass through a 100 mesh sieve to obtain fly ash fine powder;

[0035] Step 2: Add 150 parts of water solvent to the fine powder of fly ash to mix, and react under the action of ultrasonic waves. The frequency of ultrasonic waves is 40KHz, and the sound intensity is 0.6W / cm. After the reaction, enter the reaction kettle for high-temperature calcination and dry to obtain fly ash powder;

[0036] Step 3: Add 50 parts of antibacterial and antiseptic additives to the above-mentioned fly ash powder and heat and stir. The heating temperature is 50°, and the stirring time is 1H. After the mixing is completed, the reaction is carried out under the action of th...

Embodiment 2

[0055] A method for removing high-concentration chloride ions in water by using modified fly ash, comprising the following specific steps:

[0056] Step 1: Add 100 parts of fly ash to a ball mill for crushing and ball milling and sieving, the ball milling time is 50 minutes, and the sieving is to pass through a 120 mesh sieve to obtain a fine powder of fly ash;

[0057] Step 2: Add 200 parts of water solvent to the fine powder of fly ash to mix, and react under the action of ultrasonic waves. The frequency of ultrasonic waves is 45KHz, and the sound intensity is 0.7W / cm. After the reaction, enter the reaction kettle for high-temperature calcination and dry to obtain fly ash powder;

[0058] Step 3: Add 55 parts of antibacterial and antiseptic additives to the above-mentioned fly ash powder and heat and stir. The heating temperature is 65°, and the stirring time is 1H. After the mixing is completed, the reaction is carried out under the action of ultrasonic waves. The frequenc...

Embodiment 3

[0063] A method for removing high-concentration chloride ions in water by using modified fly ash, comprising the following specific steps:

[0064] Step 1: Add 100 parts of fly ash to a ball mill for pulverization and ball milling and sieving, the ball milling time is 60 minutes, and the sieving is to pass through a 150 mesh sieve to obtain fly ash fine powder;

[0065] Step 2: Add 250 parts of water solvent to the fine powder of fly ash to mix, and react under the action of ultrasonic waves. The frequency of ultrasonic waves is 50KHz, and the sound intensity is 0.8W / cm. After the reaction, enter the reaction kettle for high-temperature calcination and dry to obtain fly ash powder;

[0066] Step 3: Add 60 parts of antibacterial and antiseptic additives to the above-mentioned fly ash powder and heat and stir. The heating temperature is 80°, and the stirring time is 1H. After the mixing is completed, the reaction is carried out under the action of the ultrasonic wave. The frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com