Production device and method for synthesizing musk xylene from by-products of gamma-lactone

A technology of musk xylene and a production method, which are applied in the chemical field, can solve the problems of incineration treatment polluting the environment, increase production costs, waste of resources, etc., and achieve the effects of simple synthesis steps and comprehensive utilization of by-product resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

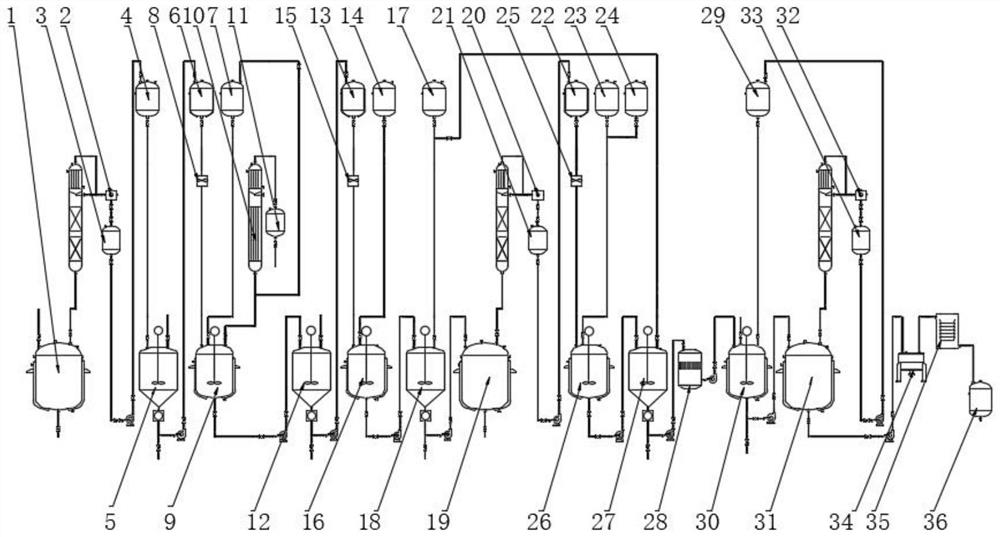

[0038] see figure 1 As shown, this embodiment is a production device for synthesizing xylene musk with gamma lactone by-products, including a gamma lactone reaction kettle 1, a spiral plate heat exchanger A2, a tert-butanol-water mixture receiving tank 3, tert-butanol-water mixture head tank 4, water separator 5, 80% tert-butanol head tank 6, hydrochloric acid head tank 7, dripping pump A8, chlorination reaction kettle 9, graphite condenser 10, dilute hydrochloric acid receiving tank 11, Washing kettle 12, chloro-tert-butane head tank 13, m-xylene head tank 14, dripping pump B15, condensation reaction kettle 16, 20% sodium hydroxide head tank 17, washing kettle A18, kettle distillation tower A19, spiral Plate heat exchanger B20, 5-tert-butyl-m-xylene vacuum receiving tank 21, 5-tert-butyl-m-xylene head tank 22, nitric acid head tank 23, sulfuric acid head tank 24, dripping pump C25, nitration reaction kettle 26 , washing kettle B27, filter 28, DMF high level tank 29, crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com