Polyester with high heat resistance and high toughness, polyester product, and preparation method and application thereof

A high-toughness, high-heat-resistant technology, applied in the field of polyester, high-heat-resistant high-toughness polyester, polyester products and their preparation, can solve problems such as insufficient heat resistance, achieve improved transparency, excellent elongation at break, The effect of high structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] One aspect of the embodiments of the present invention provides a method for preparing a class of high heat-resistant and high-toughness polyester, which includes:

[0035] reacting the first mixed reaction system comprising bishydroxyethoxy polycyclic aromatic hydrocarbons, dibasic acids or esterified products thereof, dibasic alcohols, esterification or transesterification catalysts at 160-240°C to obtain intermediate products, wherein the dibasic acids The basic acid is any one or a combination of two or more of thiophenedicarboxylic acid, furandicarboxylic acid, and terephthalic acid;

[0036] reacting the second mixed reaction system comprising the intermediate product, the polycondensation catalyst and the stabilizer at 220-290°C under vacuum conditions to obtain a high heat-resistant and high-toughness polyester;

[0037] The bishydroxyethoxy polycyclic aromatic hydrocarbon has a structure as shown in any one of formula (1) to formula (9):

[0038] .

[0039]...

Embodiment 1

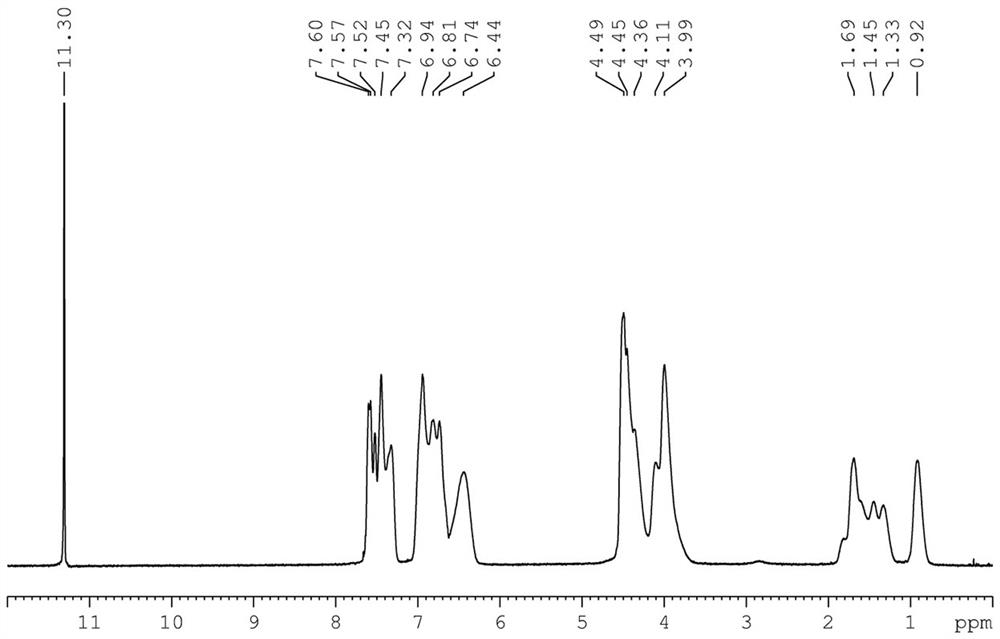

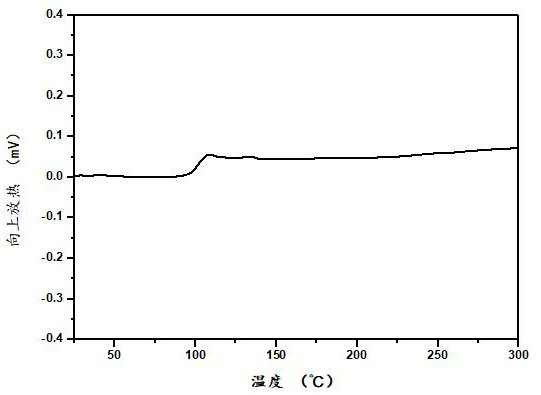

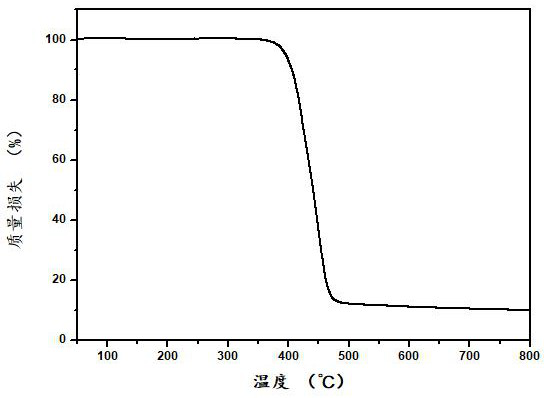

[0107] Dimethyl 2,5-thiophenedicarboxylate, bishydroxyethoxy polycyclic aromatic hydrocarbons (formula (2)), ethylene glycol, and 1,4-cyclohexanedimethanol in a molar ratio of 1:0.20:2.1:0.2 Add it into the reactor, then add the transesterification catalyst anhydrous zinc acetate with a molar weight of 0.8‰ of dimethyl 2,5-thiophenedicarboxylate, under the condition of nitrogen protection, gradually raise the temperature to 180°C for esterification, react for 4.0h, and then Add polycondensation catalyst antimony trioxide with a molar mass of dimethyl 2,5-thiophenedicarboxylate of 1.0‰, and stabilizer trimethyl phosphate with a molar weight of 1.0‰, gradually raise the temperature to 230°C, gradually reduce the vacuum degree to 50Pa, and react for 3.5 hours. The poly-2,5-thiophenedicarboxylic acid bishydroxyethoxy polycyclic aromatic hydrocarbon glycol 1,4-cyclohexanedimethanol copolyester is obtained, the structure of which is shown in formula (35). The intrinsic viscosity of ...

Embodiment 2

[0111] Add dimethyl 2,5-thiophenedicarboxylate, bishydroxyethoxy polycyclic aromatic hydrocarbon (formula (2)), and ethylene glycol into the reactor at a molar ratio of 1:0.1:2.1, and then add 2,5- Anhydrous zinc acetate with a molar mass of dimethyl thiophenedicarboxylate of 0.8‰, under the condition of nitrogen protection, gradually raise the temperature to 180°C for esterification, react for 3.5 hours, then add dimethyl 2,5-thiophenedicarboxylic acid with a molar mass of 0.8‰ antimony trioxide, 1.0‰ stabilizer trimethyl phosphate, gradually increase the temperature to 220°C, gradually reduce the vacuum degree to 20Pa, and react for 3.0h to obtain poly-2,5-thiophenedicarboxylic acid bishydroxyethoxy polycyclic aromatic hydrocarbons Ethylene glycol copolyester, the structure is as formula (36), the intrinsic viscosity of the copolyester is 0.76 dL / g, the glass transition temperature is 94 ℃, the cut-off is 700nm, the visible light transmittance is 90%, and the elongation at br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com