Steam methane reforming hydrogen production device and process

A reforming hydrogen production device and reforming hydrogen production technology, applied in the chemical industry, can solve the problems of small internal space of the reactor main body, complex internal structure of the reactor, insufficient to meet the catalytic reforming, etc. Heat loss, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

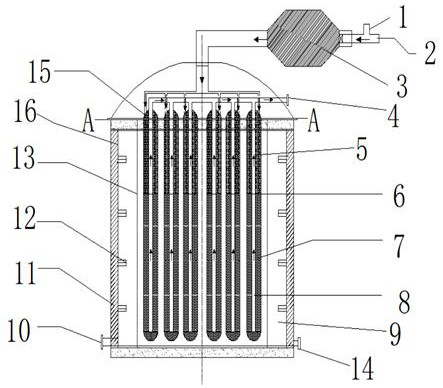

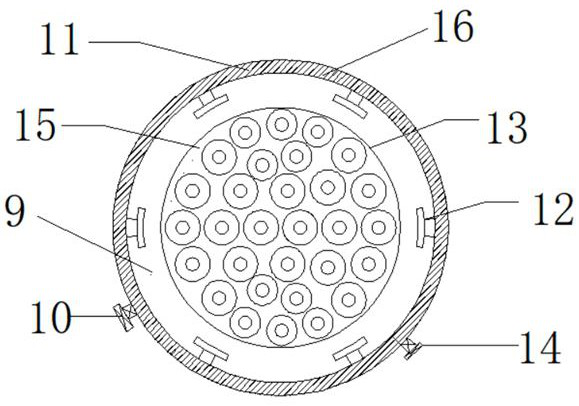

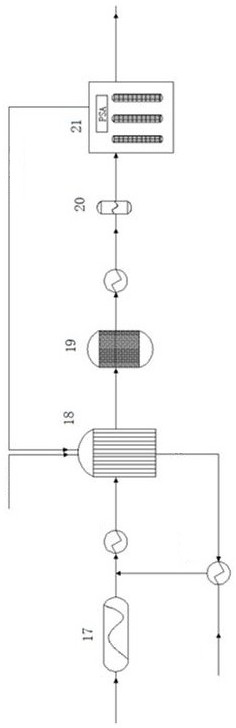

[0038] Example 1: Steam methane reforming hydrogen production device and reaction principle

[0039] Such as Figure 1-5 As shown, the steam methane reforming hydrogen production unit provided by the present invention includes a sequentially connected HDS hydrodesulfurization unit 17, a steam methane reforming hydrogen production reactor 18, a low-temperature water-gas shift reactor 19, a separator 20 and a PSA Pressure swing adsorption unit 21; the steam methane reforming hydrogen production reactor 18 includes a feed pipe at the top of the reaction device, a discharge main pipe 4, a gas mixer 3, a plurality of double-pipe SMR reactors 15 in the middle and a combustion chamber 9 and the fuel intake pipe 14 and combustion exhaust gas outlet pipe 10 at the bottom. Described feed pipe comprises methane feed pipe 1, steam feed pipe 2, and two feed pipes merge into feed main pipe, and feed main pipe connects gas mixer 3; The device is divided into an inner chamber and an annular...

Embodiment 2

[0047] Example 2: Steam methane reforming hydrogen production process

[0048] According to above-mentioned reaction technique, one group of concrete embodiment is provided:

[0049] The methane flow rate entering the gas mixer is 10L / min, and the steam flow rate is 20 L / min; the preheating part of the methane and steam double-pipe SMR reactor is preheated to about 580°C; the material ratio is steam:methane=2:1; The temperature of the reactor is controlled at 850°C and the pressure is 0.7MPa. Under the action of the catalyst, the material undergoes a reforming reaction in the reaction part of the reactor, and the hydrogen product is obtained through subsequent processes. In this example, the thermal efficiency is 76.3%, and the hydrogen production rate is 112.6 Nm 3 / h.

Embodiment 3

[0050] Example 3: Hydrogen production process by steam methane reforming

[0051] According to above-mentioned reaction technique, one group of concrete embodiment is provided:

[0052] The methane flow rate entering the gas mixer is 10L / min, and the steam flow rate is 30 L / min; the preheating part of the methane and steam double-pipe SMR reactor is preheated to about 580°C; the material ratio is steam:methane=3:1; Control the temperature of the reactor to 850°C and the pressure to 0.7MPa. Under the action of the catalyst, the material undergoes a reforming reaction in the reaction part of the reactor, and the hydrogen product is obtained through subsequent processes. In this example, the thermal efficiency is 78.8%, and the hydrogen production rate is 118.4 Nm 3 / h.

[0053] Operate through the process in the example, taking into account the influence of multiple variables, and optimize the process flow by adjusting the SCR (steam to methane ratio) and steam pressure parame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com