Method for recovering iron, aluminum and sodium from Bayer process red mud

A Bayer process red mud and iron recovery technology, applied in the field of metallurgy, can solve the problems of inability to carry out industrialization and application, low overall metal recovery rate, single variety of metal elements, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

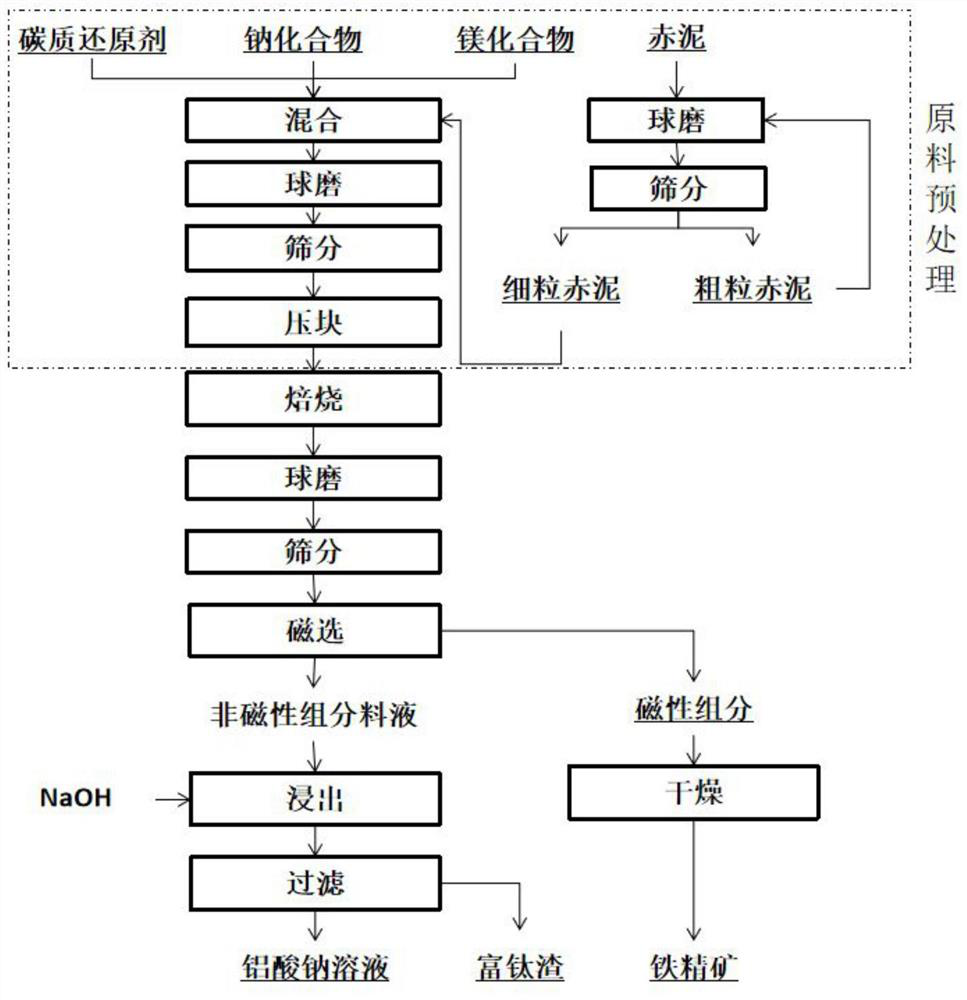

[0042] This embodiment relates to a method for comprehensively recovering iron, aluminum and sodium from Bayer process red mud, comprising the following steps:

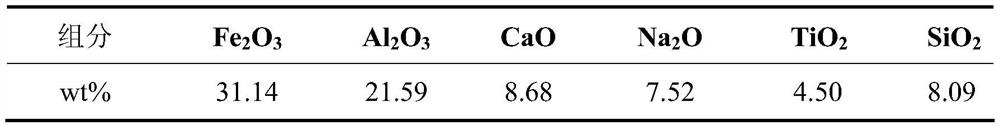

[0043] S1. Pretreatment: Mix the dried red mud fine powder with activated carbon, magnesium oxide and soda ash evenly.

[0044] According to Al in red mud 2 o 3 The content determines the Na 2 The amount of substance of O, the value range is Na 2 O / Al 2 o 3 Molar ratio is 0.9, then Na 2 The amount of substance of O is converted into the amount of soda ash added,

[0045] According to SiO in red mud 2 The content determines the amount of MgO substance, and the value range is MgO / SiO 2 The molar ratio is 1.8:1,

[0046] According to Fe in red mud 2 o 3 The content of C determines the amount of C, and the amount added is based on C / Fe 2 o 3 The molar ratio is 1.5 and an excess of 25%, and the amount of activated carbon added is calculated according to the amount of C.

[0047] Afterwards, it was ball milled...

Embodiment 2

[0053] This embodiment relates to a method for comprehensively recovering iron, aluminum and sodium from Bayer process red mud, comprising the following steps:

[0054] S1, pretreatment: the dried red mud fine powder and graphite powder, MgCO 3 and NaHCO 3 well mixed,

[0055] According to Al in red mud 2 o 3 The content determines the Na 2 The amount of substance of O, the value range is Na 2 O / Al 2 o 3 Molar ratio is 0.95, then Na 2 The amount of O substance is converted to NaHCO 3 the added amount,

[0056] According to SiO in red mud 2 The content determines the amount of MgO substance, and the value range is MgO / SiO 2 The molar ratio is 1.6:1, and then convert the amount of MgO into MgCO 3 the added amount,

[0057] According to Fe in red mud 2 o 3 The content of C determines the amount of C, and the amount added is based on C / Fe 2 o 3 The molar ratio is 2.5 and an excess of 15%, and the amount of graphite powder added is calculated according to the amoun...

Embodiment 3

[0064] This embodiment relates to a method for comprehensively recovering iron, aluminum and sodium from Bayer process red mud, comprising the following steps:

[0065] S1. Pretreatment: Mix the dried red mud fine powder with anthracite, magnesite and soda ash evenly,

[0066] According to Al in red mud 2 o 3 The content determines the Na 2 The amount of substance of O, the value range is Na 2 O / Al 2 o 3 The molar ratio is 1, and Na 2 The amount of O substance is converted to the added amount of sodium-containing compound,

[0067] According to SiO in red mud 2 The content determines the amount of MgO substance, and the value range is MgO / SiO 2 The molar ratio is 1.3:1, and then the amount of MgO is converted into the amount of magnesite added,

[0068] According to Fe in red mud 2 o 3 The content of C determines the amount of C, and the amount added is based on C / Fe 2 o 3 The molar ratio is 2.0 and an excess of 10%, and the amount of anthracite added is calculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com