Wide-temperature-range self-lubricating nano-structure film material with long service life

A technology of service life and nanostructure, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, which can solve the problems of excessive consumption of self-lubricating components and single use only

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

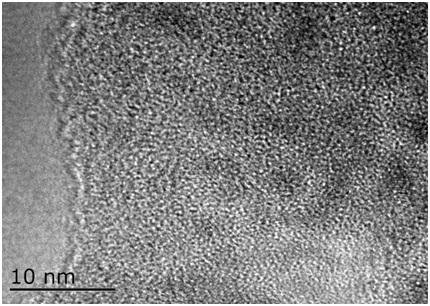

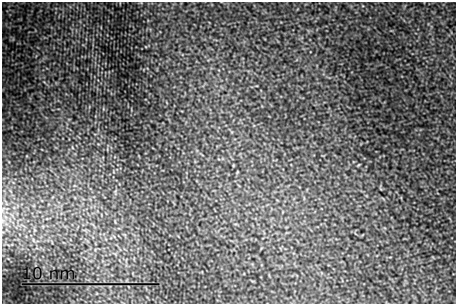

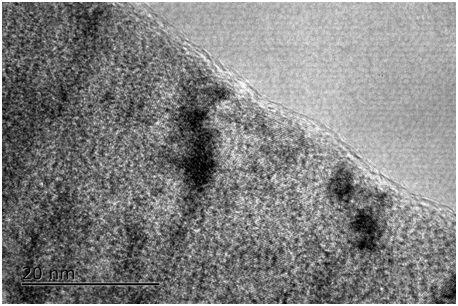

Image

Examples

Embodiment 1

[0018] Preparation of Al based on hard substrate surface 2 o 3 -Ag-C / Al 2 o 3 - A method for TiN / TiN nanostructured films comprising the steps of: Al 2 o 3 -Ag-C / Al 2 o 3 -The preparation of TiN / TiN film is completed on high-vacuum multi-target magnetron sputtering equipment. The magnetron sputtering equipment is referred to as magnetron sputtering instrument. On the three water-cooled target brackets, three stainless steel baffles are respectively placed in front of the three targets, which are automatically controlled by the computer; Al 2 o 3 The target (purity is 99.95%), Ag-C alloy target (purity is 99.9%) and TiN target (purity is 99.5%) are respectively installed on independent radio frequency cathodes, and the target diameter is 75mm;

[0019] Step 1: Treat the surface of the cemented carbide substrate as a mirror surface, then ultrasonically clean it with absolute ethanol and acetone for 15 minutes, dry it with hot air, and then put it into the film-making cab...

Embodiment 2

[0025] The difference from Example 1 is: when depositing the self-lubricating layer, the deposition time is 760s; when depositing the gradient layer, the deposition time is 90s; when depositing the hard layer, the deposition time is 300s. Subsequently, the above-mentioned deposition modulation layer was reciprocated 90 times. At this time, the thickness of the self-lubricating layer is ~60nm, the thickness of the gradient layer is ~5nm, and the thickness of the hard layer is ~60nm. The modulation ratio of the three modulation layers is 12:1:12, and the modulation period is 125nm. The film hardness was 22 GPa. Using silicon nitride as the friction pair, after a 30-minute circular friction test, the friction coefficient at room temperature, 300 °C, 600 °C and 800 °C is roughly stable at 0.4. The above friction test was repeated five times, and the film was not worn out, showing a high wide temperature range service life.

Embodiment 3

[0027] The difference from Example 1 is: when depositing the self-lubricating layer, the deposition time is 760s; when depositing the gradient layer, the deposition time is 90s; when depositing the hard layer, the deposition time is 150s. Subsequently, the above-mentioned deposition modulation layer was reciprocated 90 times. At this time, the thickness of the self-lubricating layer is ~60nm, the thickness of the gradient layer is ~5nm, and the thickness of the hard layer is ~30nm. The modulation ratio of the three modulation layers is 12:1:6, and the modulation period is 125nm. The film hardness was 17 GPa. Using silicon nitride as the friction pair, after a 30-minute circular friction test, the friction coefficient at room temperature, 300 °C, 600 °C and 800 °C is roughly stable at 0.3. The above friction test cycle was repeated five times, and the film was not worn out, showing a high wide temperature range service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com