Filter screen, preparation method thereof, air conditioner indoor unit and air purifier with filter screen

An air purifier and air conditioner indoor unit technology, applied in the field of materials, can solve the problems of unclean processing, small spread area of meltblown cloth, large resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] raw material:

[0063] (1) The polymer fiber raw material is polyethylene terephthalate (PET);

[0064] (2) Aldehyde removal particles have a median particle size of D 50 =50nm nano manganese dioxide.

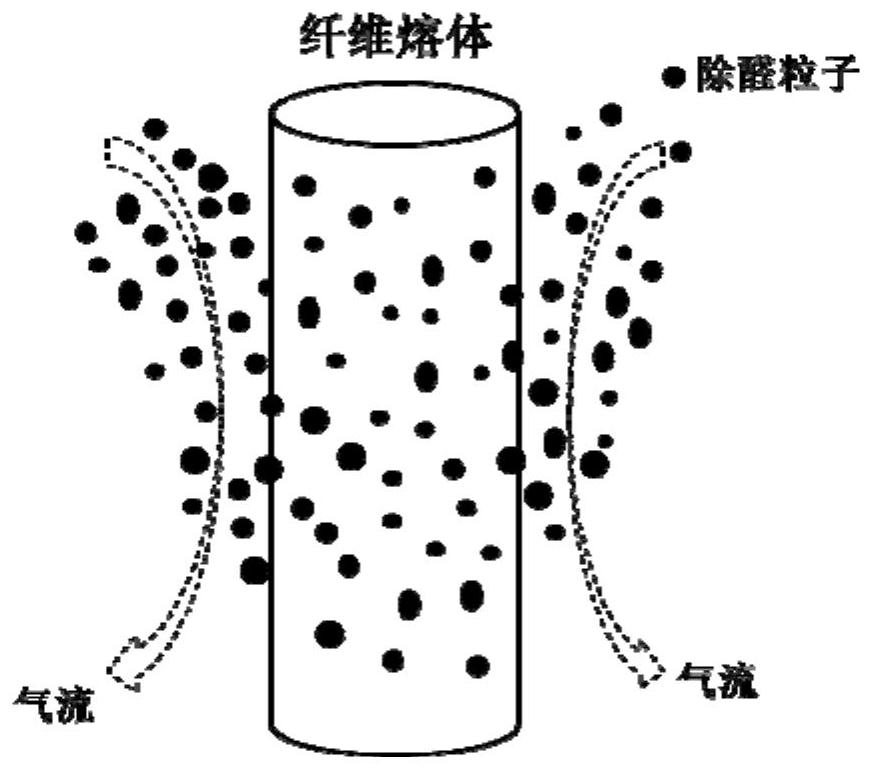

[0065] a) Melt and plasticize the dried polyethylene terephthalate (PET) fiber raw material in a screw extruder, then spray it out from the spinneret hole, and form a PET melt under the traction of the melt-blown airflow fiber.

[0066] b) The nano-manganese dioxide is blown onto the surface of the polymer fiber solution along with the blowing airflow, and the fiber with aldehyde-removing particles loaded on the surface is obtained after cooling. The temperature of the airflow is 240°C, the flow rate of the airflow is 400m / s, and the injection amount of the aldehyde-removing particles is 30mg / s.

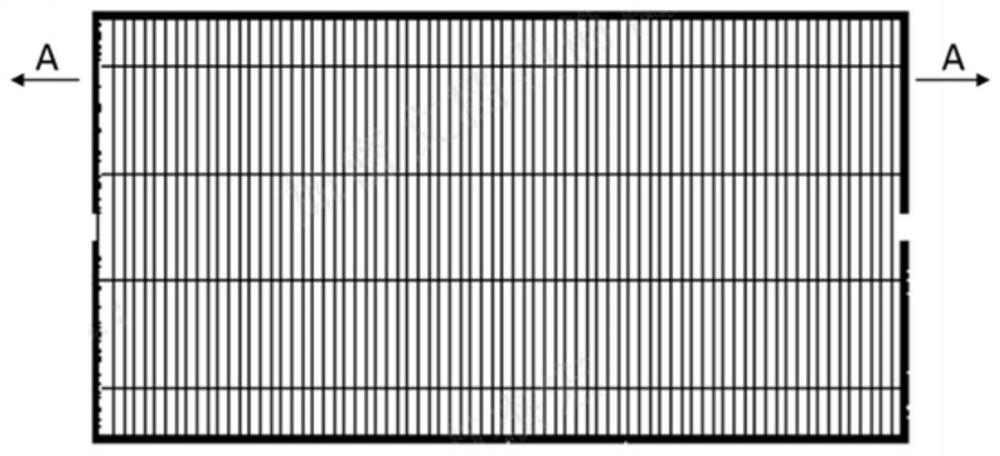

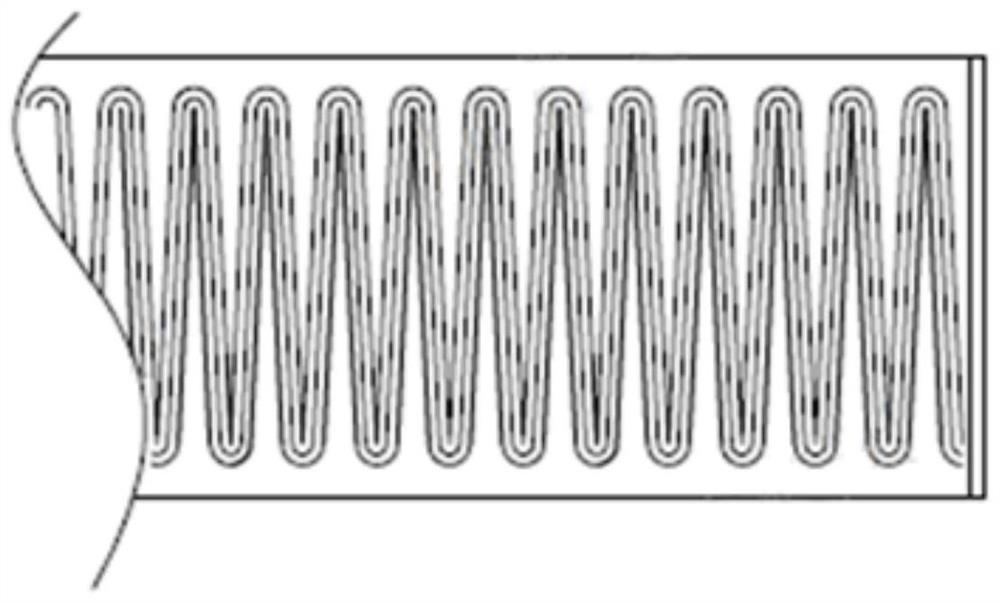

[0067] c) The polymer fibers prepared in step b fall on the web-forming curtain and bond with each other to form the formaldehyde-removing filter cloth loaded with aldehyde...

Embodiment 2

[0070] The difference from Scheme 1 is that the aldehyde removal particles have a median particle size of D 50 =200nm nano manganese dioxide.

[0071] Detect according to the method of embodiment 1: the formaldehyde clean air volume of the formaldehyde-removing filter screen with a thickness of 10mm after pleating is 90m 3 / h, the formaldehyde clean air volume of the formaldehyde removal filter with a thickness of 15mm after pleating is 130m 3 / h.

Embodiment 3

[0073] raw material:

[0074] (1) The polymer fiber raw material is polyethylene terephthalate (PET);

[0075] (2) Aldehyde removal particles have a median particle size of D 50 100nm tea polyphenols.

[0076] a) Melt and plasticize the dried polyethylene terephthalate (PET) fiber raw material in a screw extruder, then spray it out from the spinneret hole, and form a PET melt under the traction of the melt-blown airflow fiber.

[0077] b) The tea polyphenol is blown onto the surface of the polymer fiber solution along with the blowing airflow, and after cooling, the fiber with aldehyde-removing particles loaded on the surface is obtained. Wherein, the air temperature is 200° C., the air flow velocity is 450 m / s, and the injection amount of the aldehyde-removing particles is 60 mg / s.

[0078] c) The polymer fibers prepared in step b fall on the web-forming curtain and bond with each other to form the formaldehyde-removing filter cloth loaded with aldehyde-removing particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com