Catalyst for synthesizing ethylene glycol, preparation method and application thereof

A catalyst and ethylene glycol technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of non-renewable and limited storage of fossil resources, and achieve accelerated transformation, stable cycle reaction performance, The effect of increasing conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare Zr-Nb-O oxide solid acid by co-precipitation method, where Zr / Nb=1 / 1, denoted as ZrO 2 -Nb 2 o 5 (Zr / Nb=1 / 1) (the same below):

[0044] Weigh 5.345g zirconium oxynitrate dihydrate (ZrO(NO 3 ) 2 ·2h 2 O) and 10.761g of niobium oxalate were dissolved in 50mL of deionized water, mixed evenly, and ammonia water was added dropwise under vigorous stirring until the pH was 10.0, and then aged at room temperature for 24h; the resulting precipitate was filtered, washed with water until neutral, and After drying at 120 °C for 12 h, finally roasting at 400 °C for 3 h in air atmosphere to obtain ZrO 2 -Nb 2 o 5 (Zr / Nb=1 / 1) oxide solid acid.

[0045] Prepared by impregnation method from ZrO 2 -Nb 2 o 5 (Zr / Nb=1 / 1) oxide-supported multifunctional catalyst, wherein the number of parts of Ni is 8.0 parts, the number of parts of tungsten trioxide is 30.0 parts, and the number of parts of active carrier is 62.0 parts, denoted as catalyst A:

[0046] Dissolve 0.793g of...

Embodiment 2

[0053] ZrO 2 -Nb 2 o 5 (Zr / Nb=1 / 1) the preparation method of oxide solid acid is the same as embodiment 1.

[0054] ZrO 2 -Nb 2 o 5 (Zr / Nb=1 / 1) oxide-loaded multifunctional catalyst, wherein the number of Ni parts is 8.0 parts, the number of tungsten trioxide is 5.0 parts, and the number of active carriers is 87.0 parts, which is denoted as catalyst B: its Preparation by dipping method: Dissolve 0.793g of nickel nitrate hexahydrate and 0.116g of ammonium metatungstate in 3.0g of deionized water, wait until completely dissolved, mix evenly, then weigh 1.74g of the above-prepared active carrier, oscillate until evenly mixed, After drying at room temperature until most of the water has evaporated, continue to dry overnight in an oven at 110°C, then bake at 400°C for 2 hours in an air atmosphere, and finally reduce with hydrogen at 400°C for 3 hours.

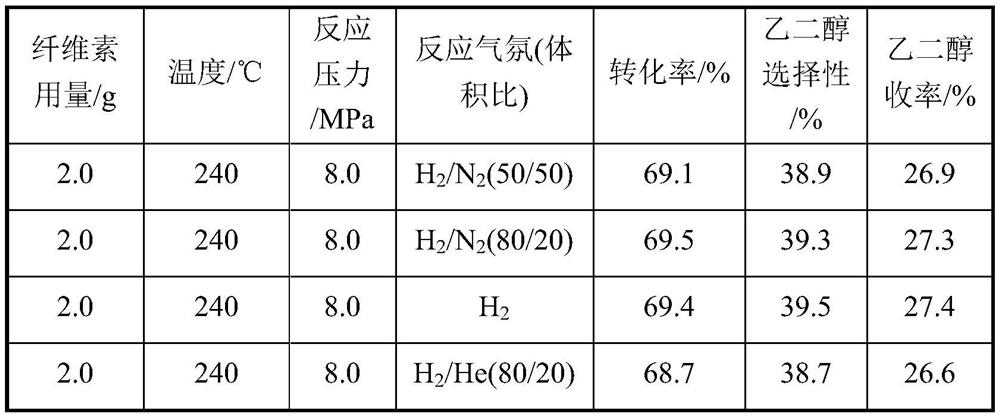

[0055] The reaction of cellulose catalytic conversion to prepare ethylene glycol is carried out in a closed reactor. Weigh 2...

Embodiment 3

[0058] ZrO 2 -Nb 2 o 5 (Zr / Nb=1 / 1) the preparation method of oxide solid acid is the same as embodiment 1.

[0059] ZrO 2 -Nb 2 o 5 (Zr / Nb=1 / 1) oxide-loaded multifunctional catalyst, wherein the number of Ni parts is 8.0 parts, the number of parts of tungsten trioxide is 15.0 parts, and the number of active carriers is 77.0 parts, denoted as catalyst C, its Preparation by impregnation method: dissolve 0.793g nickel nitrate hexahydrate and 0.349g ammonium metatungstate in 3.0g deionized water, wait for complete dissolution, mix evenly, then weigh 1.54g of the active carrier prepared above, shake until mixed evenly, After drying at room temperature until most of the water has evaporated, continue to dry overnight in an oven at 110°C, then bake at 400°C for 2 hours in an air atmosphere, and finally reduce with hydrogen at 400°C for 3 hours.

[0060] The reaction of preparing ethylene glycol by catalytic conversion of cellulose is carried out in a closed reactor. Weigh 2.0g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com