Preparation method of ternary precursor, ternary precursor, positive electrode material and lithium ion battery

A precursor, nickel ion technology, applied in the metallurgical field, can solve problems such as rate, cycle performance decline, active component reduction, battery impedance increase, etc., to promote lithium ion transmission, increase cycle life, and avoid overcharge and overdischarge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] According to a first aspect of the present invention, a method for preparing a ternary precursor comprises the following steps:

[0057] (a) Preparation of ternary precursor crystal seed: the soluble inorganic salt mixed solution of nickel ion, cobalt ion and manganese ion, precipitant, complexing agent and organic solvent are added in the first reactor, mixed reaction, when the first Stop feeding when the material in the reactor reaches full capacity, and obtain ternary precursor crystal seeds;

[0058] Wherein, the bottom liquid is contained in the first reactor; the bottom liquid includes a salting-out agent and a complexing agent;

[0059] The first reaction kettle is provided with a guide tube without a baffle, the purpose of which is to realize the uniform feeding of five raw materials including nickel, cobalt and manganese three-element mixed inorganic salt solution, liquid caustic soda, ammonia water, salting-out agent and organic solvent. , and will not distur...

Embodiment 1

[0145] The invention provides a process for a precursor of a high-magnification ternary cathode material, comprising the following steps:

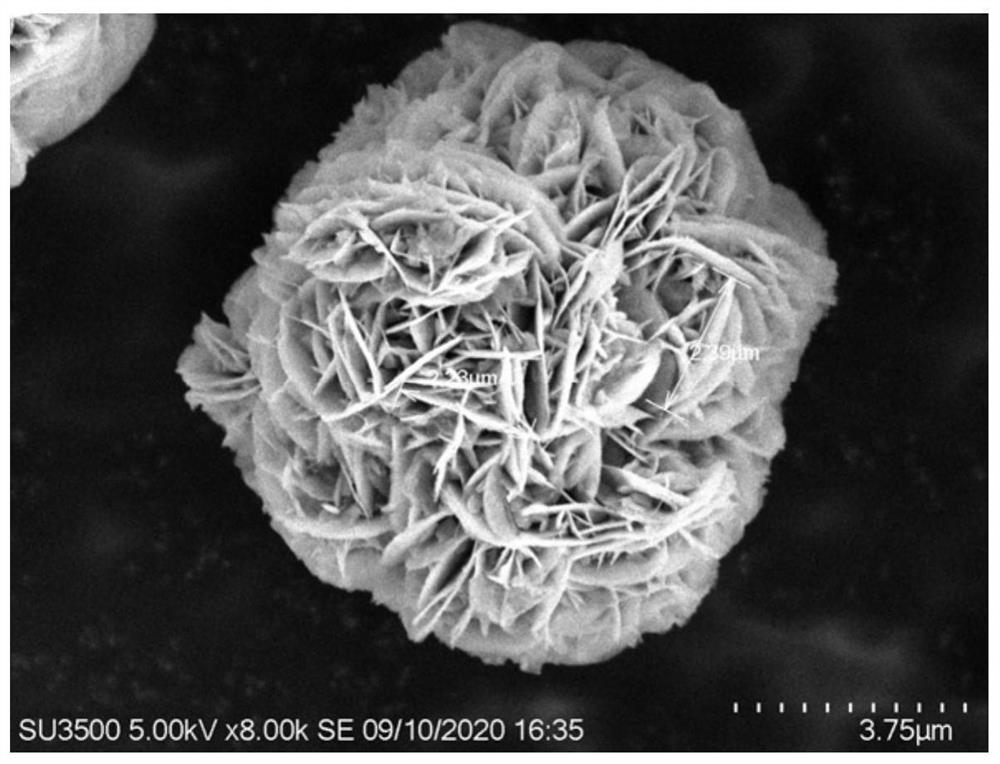

[0146] (1) The total molar weight of nickel, cobalt and manganese is 1.2mol / L, the molar ratio of nickel, cobalt and manganese is 6:2:2, mixed solution of sulfate, 25wt% NaOH solution, 12wt% ammonia solution , ethanol and other materials are fed at a constant speed by a metering pump to the reactor A containing the bottom liquid, and the temperature of the reaction system is controlled at 50 ° C, protected by a nitrogen atmosphere, and the nitrogen flow rate is 1.0m 3 / h, the pH is 10.90-11.50, the free ammonia concentration in the solution is 4.0-8.0g / L, the stirring speed is 260rpm, the flow rate of the ternary liquid is controlled at 300L / h, and the material in the reactor A reaches full and stops feeding. Among them, the concentration of ammonium root in the bottom liquid is 4.0-6.0g / L, the pH is 10.90-11.50, the concentration of sodiu...

Embodiment 2

[0155] The invention provides a process for a precursor of a high-magnification ternary cathode material, comprising the following steps:

[0156] (1) The total molar weight of nickel, cobalt and manganese is 1.5mol / L, the molar ratio of nickel, cobalt and manganese is 6:2:2, a sulfate mixed solution, 32wt% NaOH solution, and 15wt% ammonia solution , Methanol and other four materials are fed at a uniform speed by a metering pump to the reaction kettle A containing the bottom liquid at the same time, and the temperature of the reaction system is controlled at 50°C, protected by a nitrogen atmosphere, and the nitrogen flow rate is 1.0m 3 / h, the pH is 10.90-11.50, the free ammonia concentration in the solution is 4.0-8.0g / L, the stirring speed is 260rpm, the flow rate of the ternary liquid is controlled at 300L / h, and the material in the reactor A reaches full and stops feeding. Among them, the bottom liquid has an ammonium root concentration of 4.0-6.0 g / L, a pH of 10.90-11.50,...

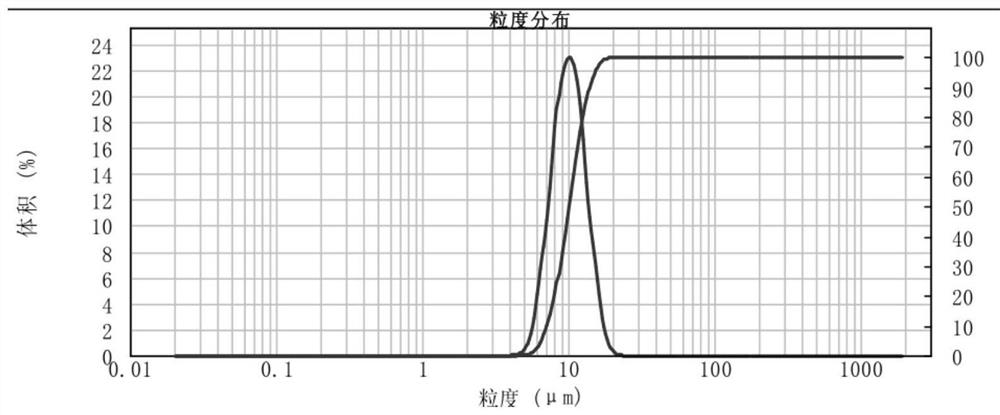

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com