By-product ceramsite based on sludge treatment by plants as well as preparation method and application of by-product ceramsite

A ceramsite and sludge technology, applied in the field of water pollution control, can solve problems such as few reports, and achieve the effects of porous internal structure, good ventilation effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

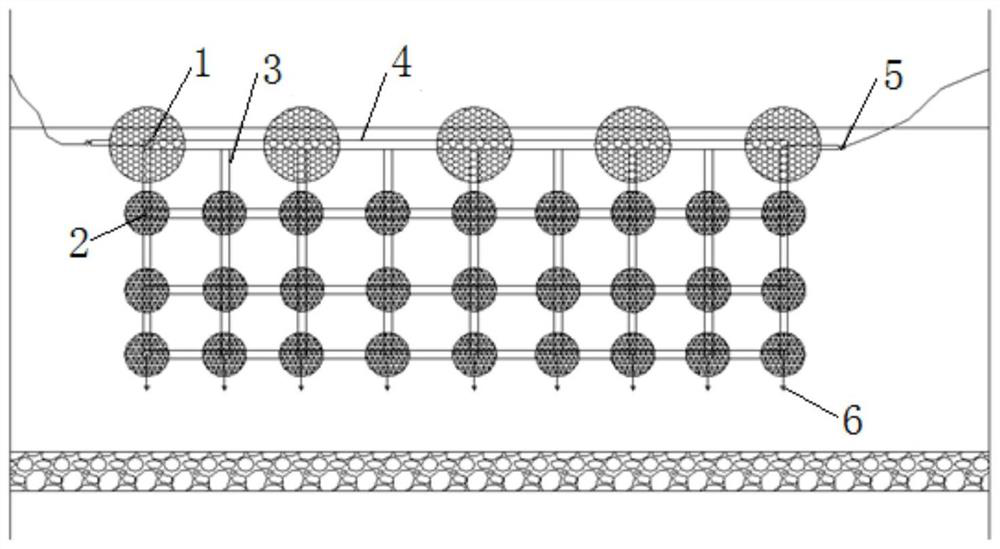

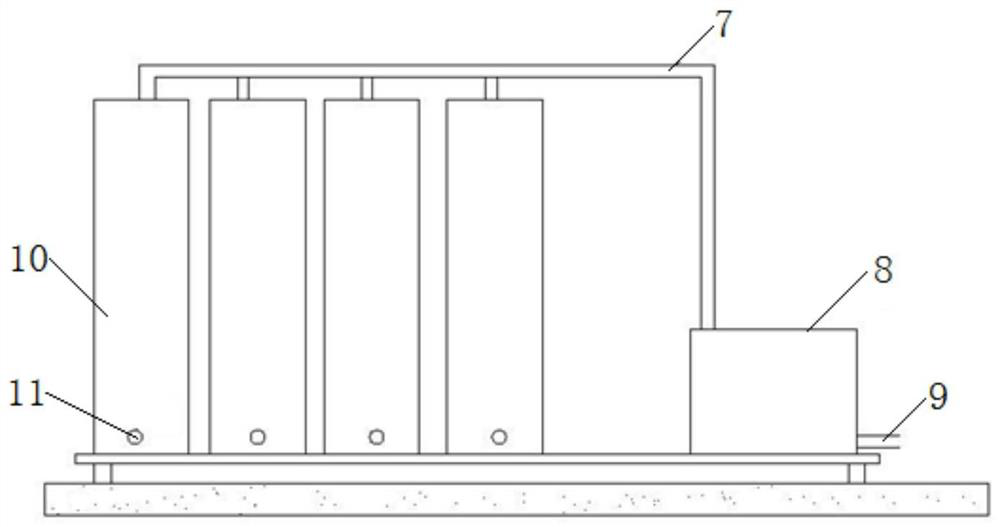

Method used

Image

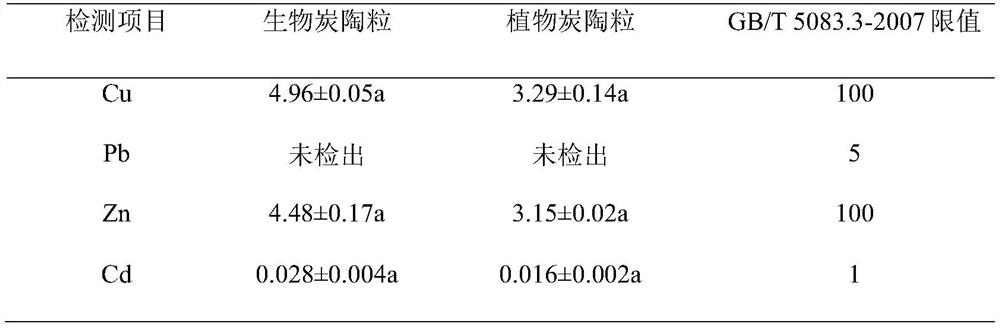

Examples

Embodiment 1

[0030] A by-product ceramsite based on plant-treated sludge, the ceramsite includes the following components by mass percentage: 30-50% of fly ash, 5-10% of biochar, 20-30% of bentonite, Magnesium carbonate 10-30%, sodium silicate 5-10%, silicon dioxide 2-5%.

[0031] The above-mentioned preparation method based on the by-product ceramsite after plant treatment sludge comprises the following steps:

[0032] S101. Preparation of biochar: use treated dry sludge (sludge that has been planted and dried) and the residual body of royal bamboo grass in the underground as raw materials, and pulverize it to a fineness of 80-100 Put it into a porcelain crucible, fill it up and compact it, cover it and put it in a box-type resistance muffle furnace, feed inert gas to drive away the air in the furnace, set the heating rate of the muffle furnace at 5-20°C / min, and carbonize The temperature is 300-600°C and the carbonization holding time is 0.5-4 hours. The raw materials are subjected to h...

Embodiment 2

[0071] The present embodiment is with embodiment 1 except following proportioning:

[0072] The composition of the ceramsite in terms of mass percentage: 7% of biochar, 40% of fly ash, 15% of bentonite, 25% of magnesium carbonate, 9% of sodium silicate, and 4% of silicon dioxide.

[0073] The above-mentioned preparation method based on the by-product ceramsite after plant treatment sludge comprises the following steps:

[0074] S101, preparation of biochar: using the treated dry sludge (planted and dried sludge) and the residual body of the royal bamboo grass in the underground as raw materials, pulverizing it to a fineness of 100 mesh, Put it into a porcelain crucible, fill it up and compact it, cover it and place it in a box-type resistance muffle furnace, feed inert gas to drive away the air in the furnace, set the heating rate of the muffle furnace to 10°C / min, and the carbonization temperature to 500°C and The carbonization holding time is 150 minutes, the raw materials ...

Embodiment 3

[0079] The present embodiment is with embodiment 1 except following proportioning:

[0080] The composition of ceramsite in terms of mass percentage: 6% of biochar, 35% of fly ash, 28% of bentonite, 20% of magnesium carbonate, 8% of sodium silicate, and 3% of silicon dioxide.

[0081] The above-mentioned by-product ceramsite preparation method based on plant treatment sludge comprises the following steps:

[0082] S101, preparation of biochar: using the treated dry sludge (planted and dried sludge) and the residue of the royal bamboo grass in the underground as raw materials, pulverizing it to a fineness of 90 mesh, Put it into a porcelain crucible, fill it up and compact it, cover it and place it in a box-type resistance muffle furnace, feed inert gas to drive away the air in the furnace, set the heating rate of the muffle furnace to 15°C / min, and the carbonization temperature to 450°C and The carbonization holding time is 200 minutes, the raw materials are subjected to high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com