Electronic-grade pyrazole aqueous solution and preparation method thereof

An aqueous solution and electronic-grade technology, which is applied in the field of electronic-grade pyrazole aqueous solution and its preparation, can solve the problems of high metal ion content that cannot meet the needs of silicon wafer cleaning and less research on purification and preparation processes, and achieve increased conductivity and simple process operation , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

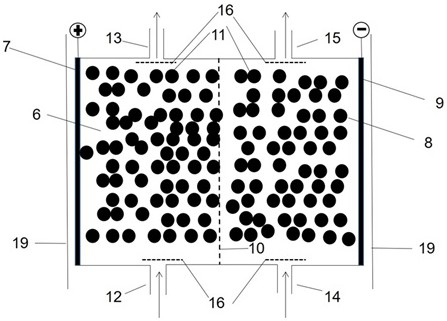

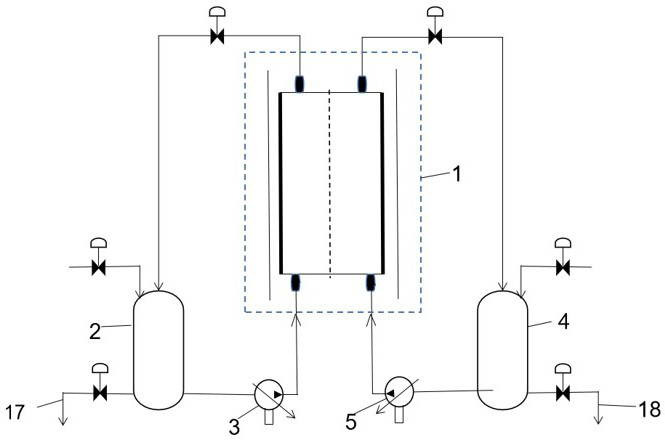

[0038] In the ultrapure electrolyzer (1) used, the cathode plate (9) is a titanium electrode (99.99% in purity), and the anode plate (7) is a platinum electrode (99.99% in purity); the cathode plate (9) and the anode plate (7) are The distance between them is 0.8 cm. The cationic exchange resin (11) used in the anode chamber (6) and the cathode chamber (8) is 001*7 type cationic exchange resin, and its particle size range is (0.315 ~ 1.25mm) ≥ 95%, wet bulk density 800 kg / m 3 , the packing density in the cathode chamber (8) is 80% of its wet bulk density, and the packing density in the anode chamber (6) is 85% of its wet bulk density. The raw material of the pyrazole aqueous solution used is an industrial grade pyrazole product, which is dissolved in water to obtain a pyrazole aqueous solution with a mass concentration of 10%.

[0039] First, add a specified amount of 001*7 cationic exchange resin (11) into the anode chamber (6) and cathode chamber (8), respectively, add Ul...

Embodiment 2

[0044] In the ultrapure electrolyzer (1) used, the cathode plate (9) is a platinum electrode (99.99% in purity), and the anode plate (7) is a titanium electrode (99.99% in purity); the cathode plate (9) and the anode plate (7) are The distance between them is 1.0 cm. The cationic exchange resin (11) used in the anode chamber (6) and the cathode chamber (8) is 2800H type cationic exchange resin, its particle size range is (0.315 ~ 1.25mm) ≥ 95%, and the wet bulk density is 810 kg / m 3 , the packing density in the cathode chamber (8) is 81% of its wet bulk density, and the packing density in the anode chamber (6) is 87% of its wet bulk density. The raw material of the pyrazole aqueous solution used is an industrial grade pyrazole product, which is dissolved in water to obtain a pyrazole aqueous solution with a mass concentration of 10%.

[0045] Firstly add specified amount of 2800H cationic exchange resin (11) into the anode chamber (6) and cathode chamber (8) Ultrapure hydro...

Embodiment 3

[0050] The cathode plate (9) in the ultrapure electrolyzer (1) used is a titanium-iridium alloy electrode (purity 99.99%), and the anode plate (7) is a platinum electrode (purity 99.99%); the cathode plate (9) and the anode plate (7 ) with a distance of 1.5 cm. The cationic exchange resin (11) used in the anode chamber (6) and the cathode chamber (8) is 2800H type cationic exchange resin, its particle size range is (0.45 ~ 1.25mm) ≥ 95%, and the wet bulk density is 780 kg / m 3 , the packing density in the cathode chamber (8) is 84% of its wet bulk density, and the packing density in the anode chamber (6) is 89% of its wet bulk density. The raw material of the pyrazole aqueous solution used is an industrial grade pyrazole product, which is dissolved in water to obtain a pyrazole aqueous solution with a mass concentration of 20%.

[0051] Firstly add specified amount of 2800H cationic exchange resin (11) into the anode chamber (6) and cathode chamber (8) Ultrapure hydrochlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com