Nano-silica modified geopolymer anticorrosive mortar and preparation method thereof

A nano-silica, geopolymer technology, applied in solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problems of weak acid corrosion resistance, easy cracking, and low service life of cement mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention also provides a preparation method for the above-mentioned nano-silica modified high-performance geopolymer anti-corrosion mortar, which includes: first mixing fly ash, metakaolin, nano-silica, polycarboxylate water reducer, expansion agent and Put the water into the mixer, stir at a speed of 60-120r / min for 3-5min, then add sodium silicate, water-based epoxy resin emulsion, and water-based epoxy curing agent, increase the speed to 1000r / min and continue stirring for 2-3min, then Add quartz sand and continue stirring at a speed of 60-120r / min for 1-2min, maintain a stirring speed of 60-120r / min, and finally add polyvinyl alcohol fiber and stir for 2-3min to fully mix well.

[0020] Analyzed from the functional mechanism, compared with the prior art, the present invention has the advantages of:

[0021] (1) The geopolymer is a kind of AlO 4 and SiO 4 An inorganic polymer with a three-dimensional network structure composed of tetrahedral structural...

Embodiment 1

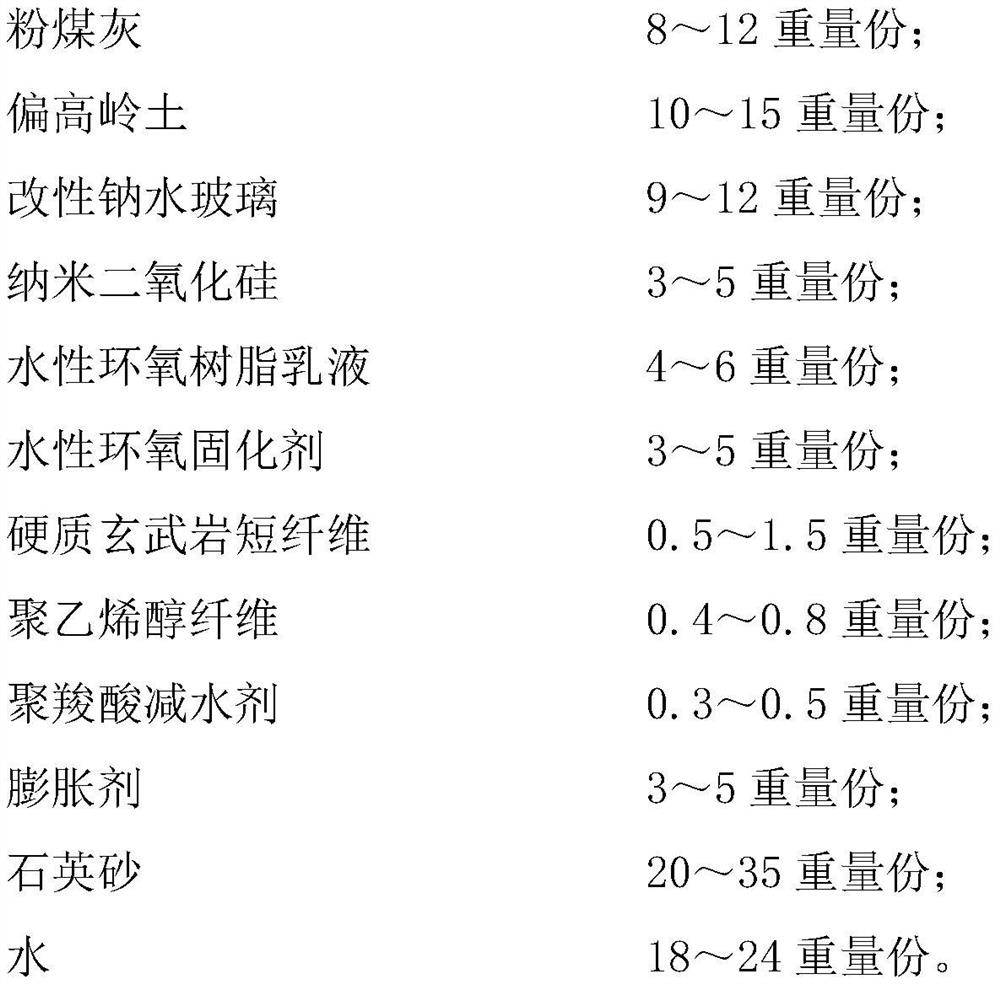

[0028] The weight ratio of each component of a nano-silica modified high-performance geopolymer anti-corrosion mortar provided by the invention is:

[0029]

[0030] Put fly ash, metakaolin, nano-silica, polycarboxylate superplasticizer, expansion agent and water into the mixer, stir at a speed of 60-120r / min for 3-5min, then add sodium water glass, water-based Epoxy resin emulsion, water-based epoxy curing agent, increase the speed to 1000r / min and continue to stir for 2-3 minutes, then add quartz sand and continue to stir at 60-120r / min for 1-2min, maintain the stirring speed of 60-120r / min and finally add Stir the polyvinyl alcohol fiber for 2 to 3 minutes to mix well and evenly.

Embodiment 2

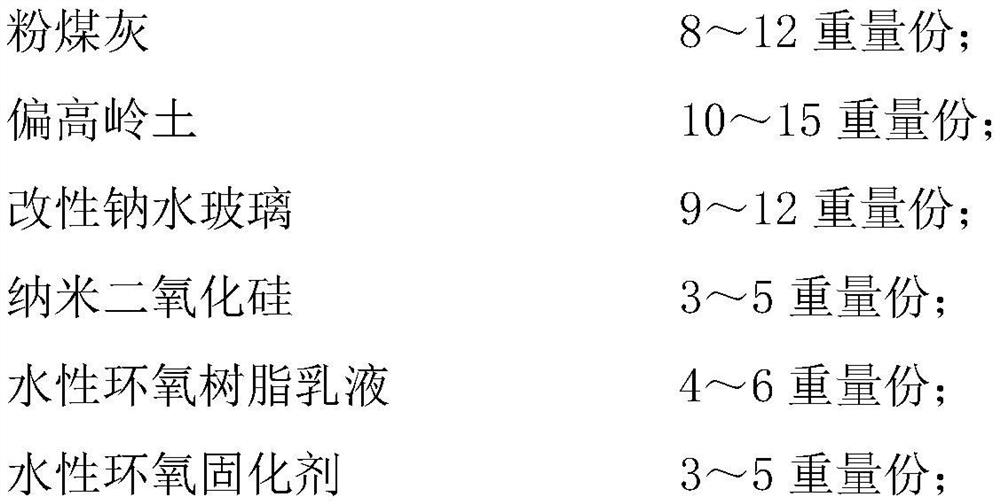

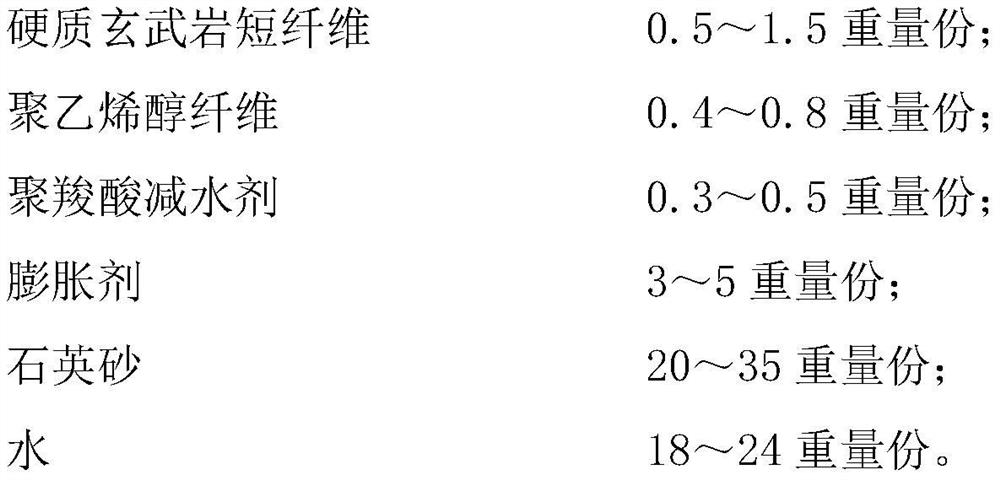

[0032] The weight ratio of each component of a nano-silica modified high-performance geopolymer anti-corrosion mortar provided by the invention is:

[0033]

[0034]

[0035] Put fly ash, metakaolin, nano-silica, polycarboxylate superplasticizer, expansion agent and water into the mixer, stir at a speed of 60-120r / min for 3-5min, then add sodium water glass, water-based Epoxy resin emulsion, water-based epoxy curing agent, increase the speed to 1000r / min and continue to stir for 2-3 minutes, then add quartz sand and continue to stir at 60-120r / min for 1-2min, maintain the stirring speed of 60-120r / min and finally add Stir the polyvinyl alcohol fiber for 2 to 3 minutes to mix well and evenly.

[0036]A nano-silica-modified high-performance polymer anti-corrosion mortar prepared in the above-mentioned embodiments of the present invention has higher mechanical properties, cohesiveness, impermeability, and resistance to acid, alkali and salt corrosion compared with the prior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com