A method for improving the thermoelectric properties of bismuth telluride-based pseudo-ternary thermoelectric materials by co-doping er and ag

A bismuth telluride-based pseudo-thermoelectric material technology, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of increasing device production costs, reducing device reliability, and poor mechanical properties. Achieve the effect of improving electrical transport performance, reducing thermal conductivity, and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

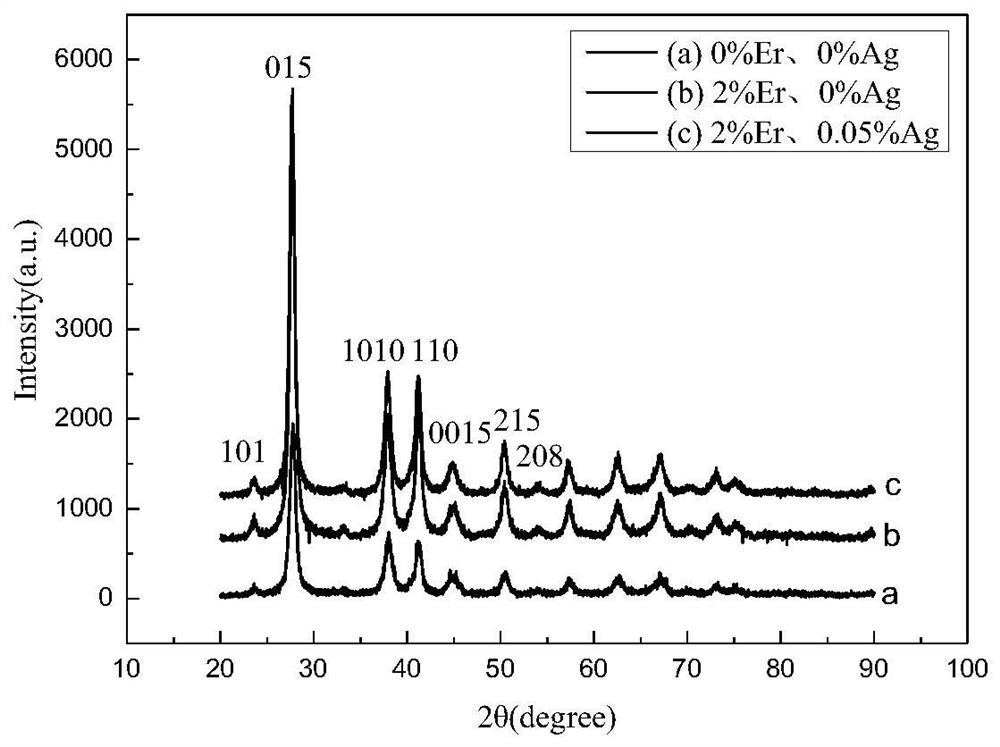

[0029] A method for improving the thermoelectric performance of a bismuth telluride-based pseudo-ternary thermoelectric material by co-doping with Er and Ag, the steps are as follows:

[0030] S1. Weigh elemental Bi, elemental Sb, elemental Se and elemental Te according to the molar ratio of Bi element, Sb element, Te element and Se element as 180:2:285:15, and weigh elemental Bi, elemental Sb, elemental Se and elemental element Te is mixed, and then rare earth element Er and transition metal element Ag are added to obtain a mixture, wherein the doping amount of rare earth element Er is 0.1% of the total mass, and the doping amount of metal Ag is 0.05% of the total mass, and the mixture is pulverized into particles The diameter is 1mm-10mm, and petroleum ether is used as the ball milling medium. Under the conditions of the rotating speed of 410r / min and the ball-to-material ratio of 10:1, mechanical ball milling is carried out for 20 hours to obtain Er and Ag co-doped bismuth t...

Embodiment 2

[0034] A method for improving the thermoelectric performance of a bismuth telluride-based pseudo-ternary thermoelectric material by co-doping with Er and Ag, the steps are as follows:

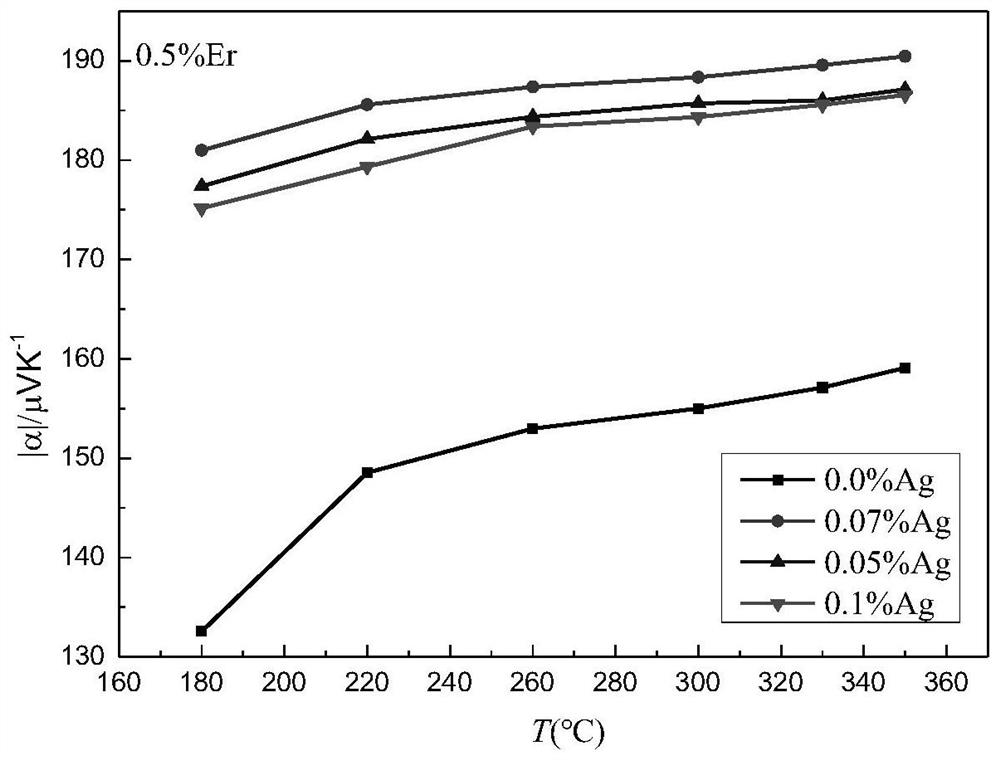

[0035] S1. Weigh elemental Bi, elemental Sb, elemental Se and elemental Te according to the molar ratio of Bi element, Sb element, Te element and Se element as 180:2:285:15, and weigh elemental Bi, elemental Sb, elemental Se and elemental element Te is mixed, and then rare earth element Er and transition metal element Ag are added to obtain a mixture, wherein the doping amount of rare earth element Er is 0.6% of the total mass, and the doping amount of metal Ag is 0.07% of the total mass, and the mixture is pulverized into particles The diameter is 1mm-10mm, and petroleum ether is used as the ball milling medium. Under the conditions of the rotating speed of 410r / min and the ball-to-material ratio of 10:1, mechanical ball milling is carried out for 20 hours to obtain Er and Ag co-doped bismuth t...

Embodiment 3

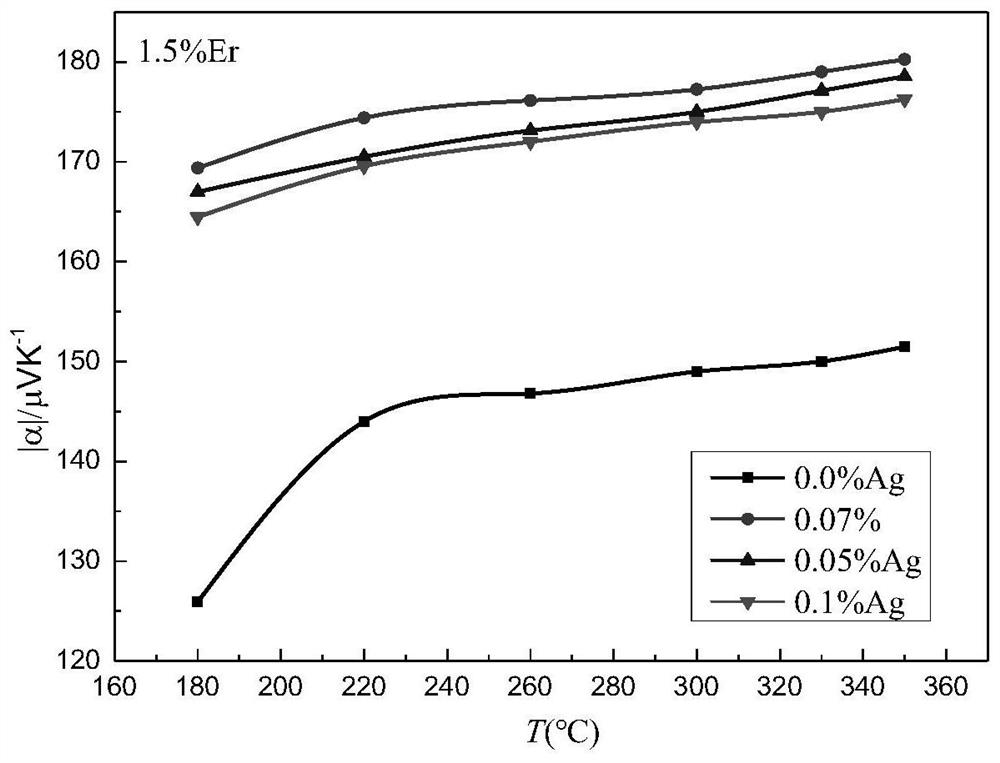

[0039] A method for improving the thermoelectric performance of a bismuth telluride-based pseudo-ternary thermoelectric material by co-doping with Er and Ag, the steps are as follows:

[0040] S1. Weigh elemental Bi, elemental Sb, elemental Se and elemental Te according to the molar ratio of Bi element, Sb element, Te element and Se element as 180:2:285:15, and weigh elemental Bi, elemental Sb, elemental Se and elemental element Te is mixed, and then rare earth element Er and transition metal element Ag are added to obtain a mixture, wherein the doping amount of rare earth element Er is 2.0% of the total mass, and the doping amount of metal Ag is 0.1% of the total mass, and the mixture is pulverized into particles The diameter is 1mm-10mm, and petroleum ether is used as the ball milling medium. Under the conditions of the rotating speed of 410r / min and the ball-to-material ratio of 10:1, mechanical ball milling is carried out for 20 hours to obtain Er and Ag co-doped bismuth te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com