Extraction process of salidroside

A technology of salidroside and extraction process, which is applied in the direction of physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, sugar derivatives, etc., and can solve problems such as the inability to obtain pure salidroside, Achieve the effect of convenient recycling, improving purity and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

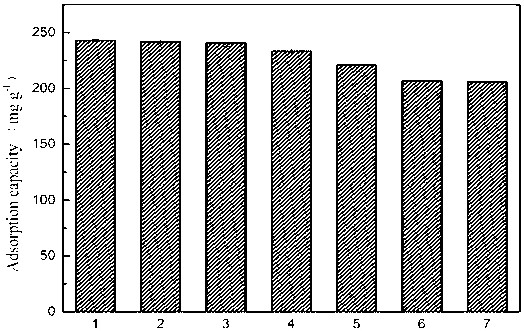

Examples

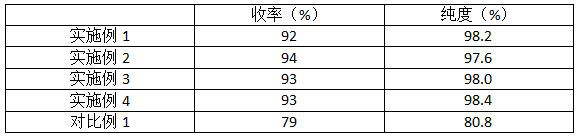

Embodiment 1

[0037] The process of extracting salidroside in the present embodiment is as follows:

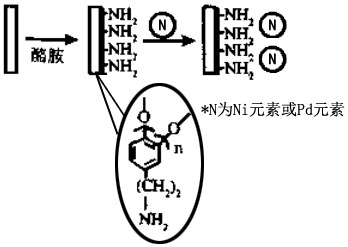

[0038] 1. Preparation of Magnetic Particles

[0039](1) Weigh 3.46g of ferric chloride hexahydrate and place it in 70ml of ethylene glycol, slowly add 7.66g of anhydrous sodium acetate, stir vigorously at room temperature for 30min until it is completely dissolved, and obtain a uniform yellow solution, then dissolve the solution Transfer to a Teflon-lined stainless steel high-pressure reactor, react at 200 degrees Celsius for 12 hours, and obtain a black precipitate, wash with absolute ethanol for 3 times and then with deionized water for 3 times, and vacuum-dry at 60 degrees Celsius for 12 hours to obtain ferric oxide particles ;

[0040] (2) Weigh 200mg of ferric oxide particles that have been prepared and add them to a solution containing 100ml of ethanol / water (4 / 1, v / v) and 2ml of ammonia water (mass concentration 28%), sonicate for 30min, add 2ml of TEOS (positive Ethyl silicate), s...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is that pdI 2 (Ph 3 P) 3 - THF solution replaced by pdCl 2 (Ph 3 P) 2 -DMSO solution; the extraction steps of salidroside are:

[0054] (1) Take 50mg of magnetic particles and add them to 5ml of Rhodiola rosea extract, mix and incubate, shake on a vortex shaker for 10 minutes, then place in a strong magnetic field to attract, remove the supernatant, and take out the magnetic particles;

[0055] (2) Rinse the magnetic particles taken out in step (1) with 5ml of absolute ethanol, oscillate on a vortex oscillator for 10 minutes, place in a strong magnetic field to attract, remove the supernatant, take out the magnetic particles, and repeat twice;

[0056] (3) Soak the magnetic particles taken out in step (2) in 5ml of sodium acetate-acetic acid-ethanol solution with pH=3.6, oscillate ultrasonically for 20min, then add 5ml70% ethanol solution, oscillate ultrasonically for 30min, in the obtained system, The clear ...

Embodiment 3

[0060] The difference between this embodiment and embodiment 1 is that pdI 2 (Ph 3 P) 3 - THF solution replaced by NiCl 2 (Ph 3 P) 2 - DMF solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com