High-hardness polyester film as well as preparation method and application thereof

A polyester film and high hardness technology, applied in the field of polymer materials, can solve the problems of easy scratches, low surface tension, and low hardness, and achieve the effects of good transparency and stability, simple process, and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a metal particle-based functionalized polyester film and a preparation method thereof, which specifically includes the following steps:

[0030] (a) Add ethylene glycol and dimethyl terephthalate (the molar ratio is 2:1) to the reaction tank of the rectification tower, and add cobalt acetate tetrahydrate (as a transesterification catalyst, its addition is in oligomerization about 500ppm in the product) and carry out transesterification at 140°C to obtain oligomers (i.e., diethylene glycol terephthalate); then raise the temperature in the reaction tank to 250°C so that the generated methanol is continuously distilled out , as the transesterification proceeds, diethylene glycol terephthalate is obtained until the transesterification reaction rate is about 98%;

[0031] (b) Under the condition of 100 degrees, add 200ppm of calcium carbonate in terms of calcium element and 400ppm of phosphoric acid in phosphorus element to the excess ethylene glycol...

Embodiment 2

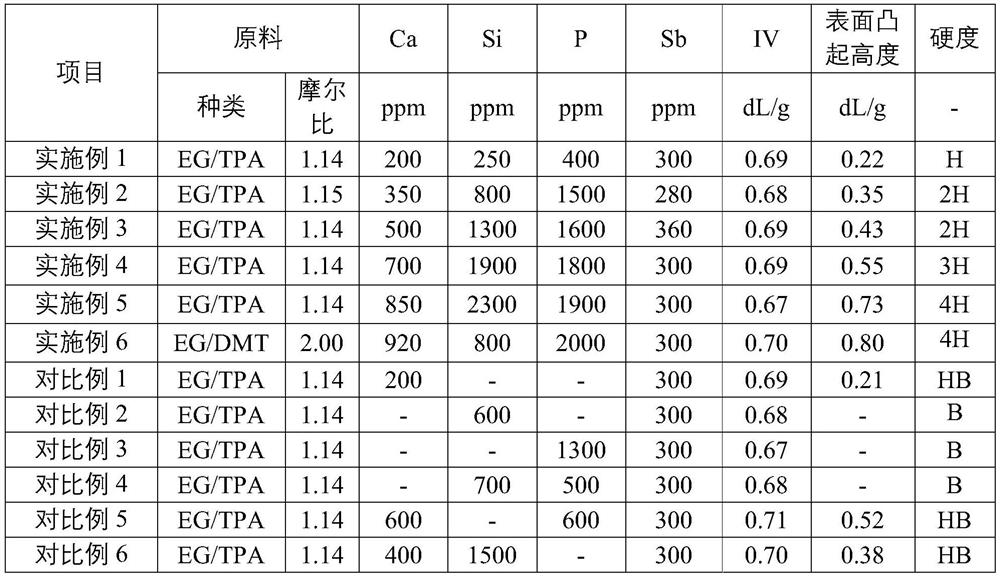

[0033] The present embodiment provides a kind of based on metal particle functionalized polyester film and preparation method thereof, and it is basically consistent with embodiment 1, difference is: in step (b), add the calcium carbonate of copper element 350ppm, with 800ppm of dimethyl ester silicone oil in terms of silicon element, 1500ppm of phosphoric acid in terms of phosphorus element, and 280ppm of antimony trioxide.

Embodiment 3

[0035] The present embodiment provides a kind of based on metal particle functionalized polyester film and preparation method thereof, and it is basically consistent with embodiment 1, difference is: in step (b), add the calcium carbonate of calcium element 500ppm, with 1300ppm of methyl silicone oil in terms of silicon element, 1600ppm of phosphoric acid in terms of phosphorus element, and 360ppm of antimony trioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com