Modified PET material and preparation method thereof

A modification and raw material technology, applied in the field of modified PET materials and their preparation, can solve the problems of hindering the movement of molecular segments, high glass transition temperature, difficult molding and processing, etc., to reduce the two-phase interface energy, improve the adhesion, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a modified PET material, comprising the following preparation steps:

[0045]A1. Weigh the following raw materials by weight: 75kgPET, 15kgPA66, 5kgPEN, 0.1kg antioxidant 1010, 5kg kaolin, 7.5kgPP-g-MAH, 1.0kg2-methyl-2 acrylate-2 hydroxyethyl phosphate, 2kg glass fiber;

[0046] A2. Put the weighed PET, PA66, PP-g-MAH, 2-methyl-2 acrylate-2 hydroxyethyl phosphate into the mixer and mix, then add antioxidant, PEN, kaolin and mix Mixture A is obtained;

[0047] A3. Mix the mixture A with the glass fiber drawn in through the side inlet of the extruder to obtain the mixture B;

[0048] A4, the mixture B is extruded and pelletized through an extruder to obtain modified PET pellets;

[0049] A5. The modified PET pellets are made into modified PET splines through an injection molding machine.

[0050] Among them, the extruder is a twin-screw extruder, and the twin-screw extruder can be divided into six zones between the feeding port and the tempera...

Embodiment 2-5

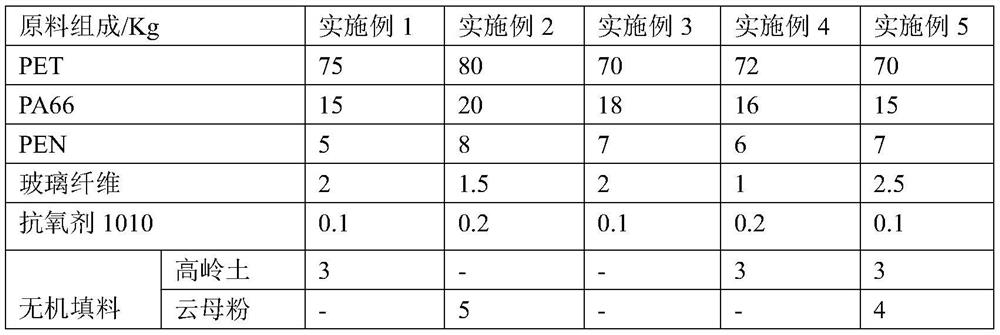

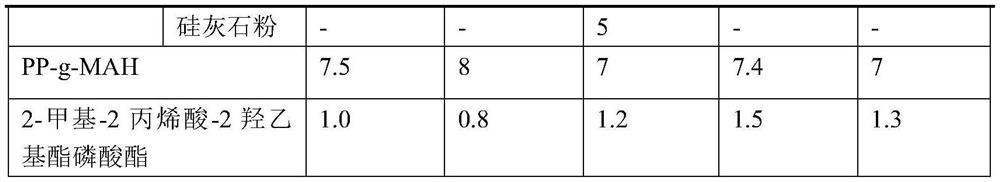

[0052] The preparation method of the modified PET material of embodiment 2-5 is identical with embodiment 1, and difference only is as shown in table 1:

[0053] Raw material composition and consumption of table 1 embodiment 1-5 modified PET material

[0054]

[0055]

Embodiment 6

[0057] The preparation method of the modified PET material in Example 6 is the same as that in Example 1, except that the compatibilizer is maleic anhydride grafted EPDM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com