Water-based epoxy anticorrosive paint for containers, and preparation method and application thereof

A technology of water-based epoxy and anti-corrosion coatings, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc. It can solve the problems of water-based epoxy coatings such as poor resistance to humidity and heat and salt spray, and is not environmentally friendly, so as to improve the system Compatibility, effect of improving mechanical properties and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

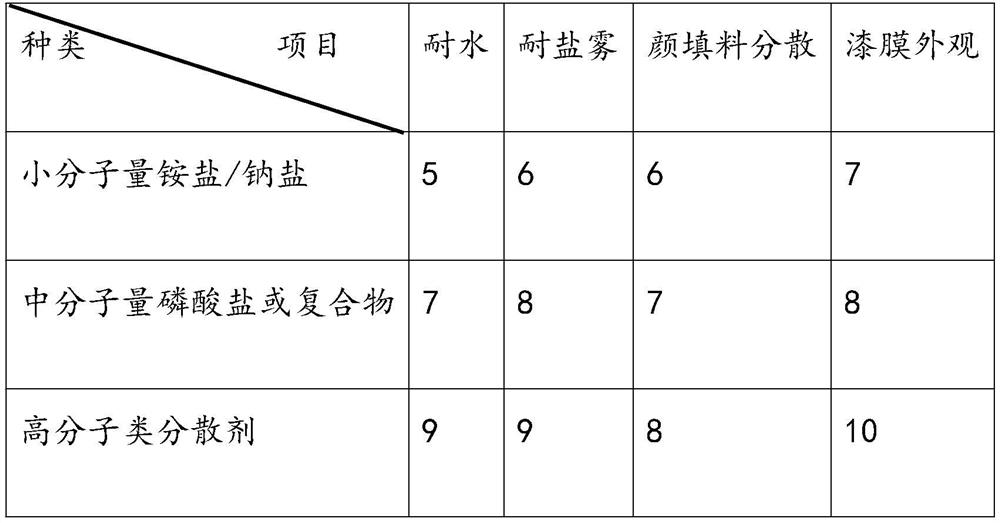

[0025] The influence of embodiment 1 different types of dispersants on coating properties

[0026] Comparative analysis of common dispersant categories, dispersants are divided into small molecular weight ammonium salts / sodium salts, medium molecular weight phosphates or complexes, and high molecular weight main chain / anchor group polymer dispersants. And prepare the paint by:

[0027] S0. Put an appropriate amount of epoxy resin and deionized water in a three-necked flask and heat it to 60-70°C, add butanol to disperse evenly, then add emulsifier and dispersant in the dispersed state, and add polydimethylsilane in turn after the dispersion is even The oxane and silane coupling agents are dispersed and emulsified at high speed, and finally form a silicone-modified epoxy emulsion with suitable particle size and good condition through condensation polymerization.

[0028] S1. Mix and disperse pigments and fillers with deionized water and some functional additives evenly, then d...

Embodiment 2

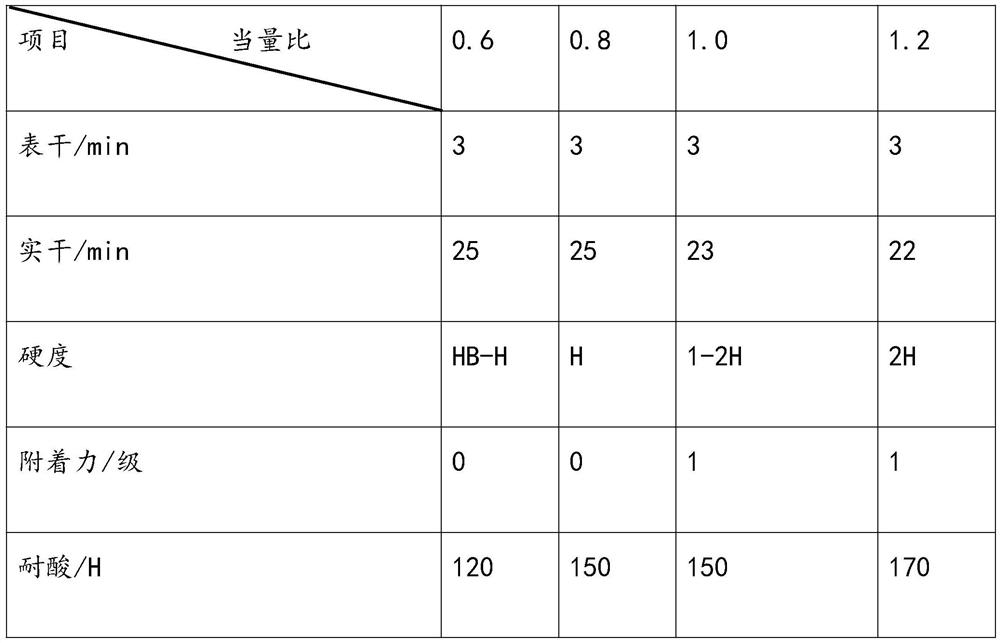

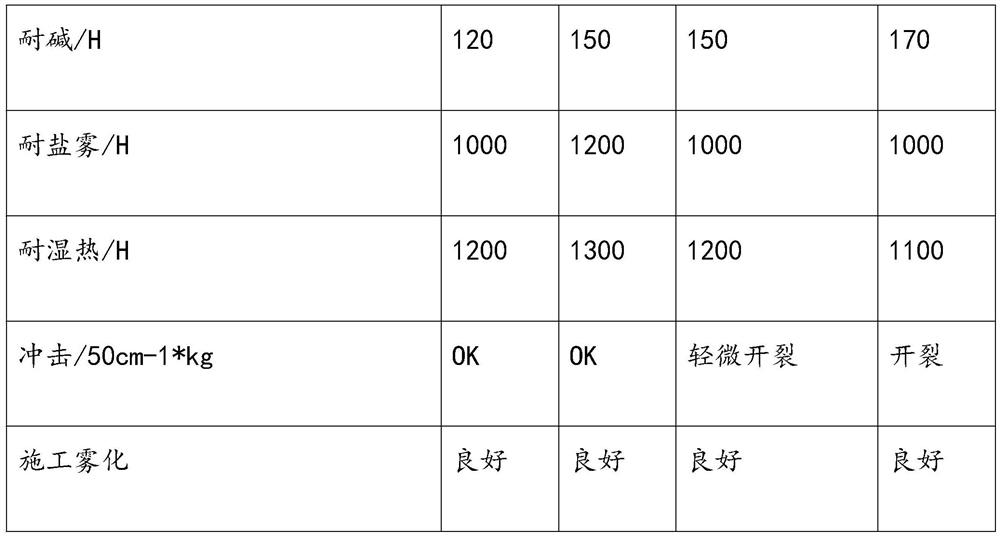

[0035] The impact of the equivalent ratio of embodiment 2 different epoxy resins and amines on coating properties

[0036] Prepare the anti-corrosion coating according to the following scheme:

[0037] The coating includes two components, A and B, and the B component includes an amine curing agent, a B component functional auxiliary agent and an alcohol ether organic solvent, and the A component includes 30.0% by weight. ~35wt.% organosilicon-modified epoxy emulsion, described organosilicon-modified epoxy emulsion by weight percentage, comprises the following components:

[0038] 40.0-45.0wt.% epoxy resin; 5.0-6.0wt.% butanol; 10.0-15.0wt.% hydroxyl-terminated polydimethylsiloxane; 5.0-7.0wt.% emulsifier; 4.0-5.0wt.% polymer dispersant; 10.0-13.0wt.% silane coupling agent, and the balance is deionized water.

[0039] The B component functional additives include an anti-flash rust agent, a drier and a pH regulator, the anti-flash rust agent is FR-355, and the amount added is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com