Engineering bacterium for producing alpha-arbutin, construction method and application thereof

A construction method and technology of arbutin, applied in the field of bioengineering, can solve the problems of toxicity, unfavorable industrial production of α-arbutin, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Recombinant plasmid pZE - pchB - salABCD - GD - xgtA

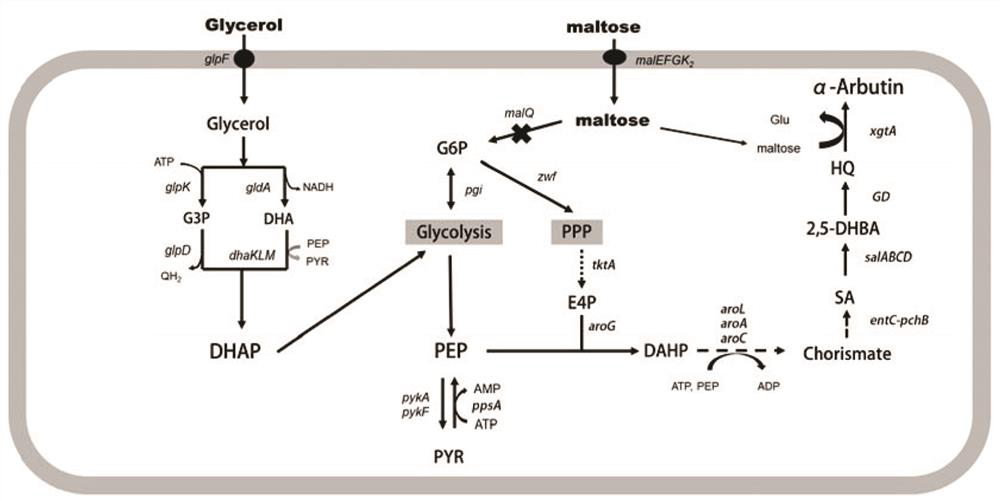

[0037] The recombinant plasmid pZE-pchB-salABCD-GD-xgtA provided in this example is mainly obtained by linking the genes xgtA, pchB, salABCD, and GD to the E. coli expression vector pZE12-luc.

[0038] The method for constructing the above-mentioned recombinant plasmid provided in this example specifically includes the following steps. Screening of bacterial, fungal or protein engineered enzymes encoding α-glucosidase (XgtA), isochoristate pyruvate lyase (PchB), anthranilate 5-hydroxylase (SalABCD) and gentisate decarboxylase (GD) gene. PCR amplification of target genes encoding α-glucosidase (XgtA), isochorisate pyruvate lyase (PchB), anthranilate 5-hydroxylase (SalABCD) and gentisate decarboxylase (GD) After the target fragment is obtained, the target fragment and the vector are digested with an appropriate enzyme, and the digested fragment is recovered, and then inserted into the expression plasmid pZE12-luc (P...

Embodiment 2

[0040] Engineering bacteria producing α-arbutin: Recombinant Escherichia coli BW1, BW2, BW3

[0041] The engineering bacteria producing α-arbutin provided by the present invention have no special requirements on the type of host strain used to construct the expression plasmid. In the embodiment of the present invention, strain BW25113 is used as the initial host for constructing the plasmid.

[0042] First, pick fresh BW25113 colonies and inoculate them into 4 mL of LB medium, incubate at 37°C for 8–12 h, then inoculate 1 mL into 100 mL of LB medium, and incubate at 37°C until OD 600 When the growth reaches 0.6, centrifuge at 6000 rpm for 10 min at 4 °C to collect the bacteria, wash with 10 mL of 10% pre-cooled glycerol, centrifuge at 6000 rpm for 10 min, repeat the glycerol washing step, and drain the remaining glycerol as much as possible after centrifugation. Finally, an appropriate amount of 10% glycerol was added to resuspend the cells to obtain competent cells. Take 90 ...

Embodiment 3

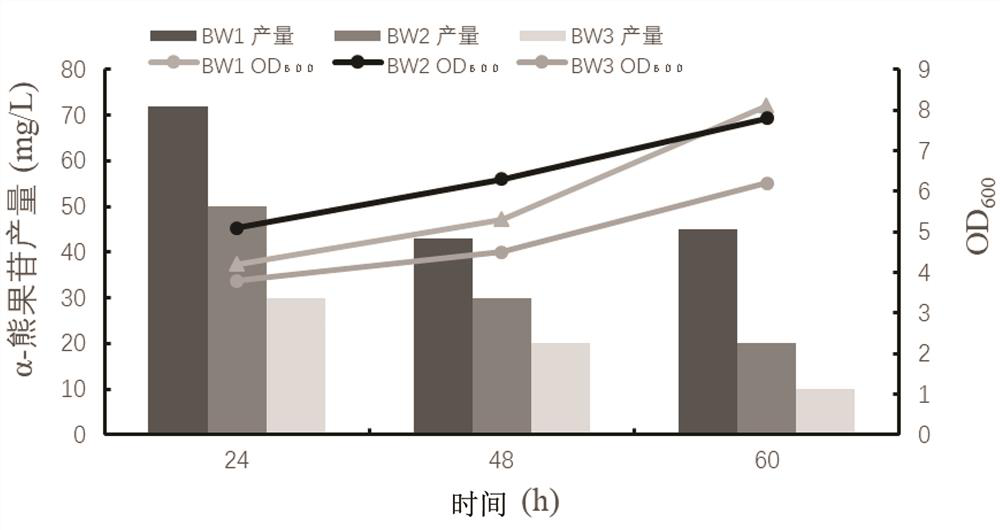

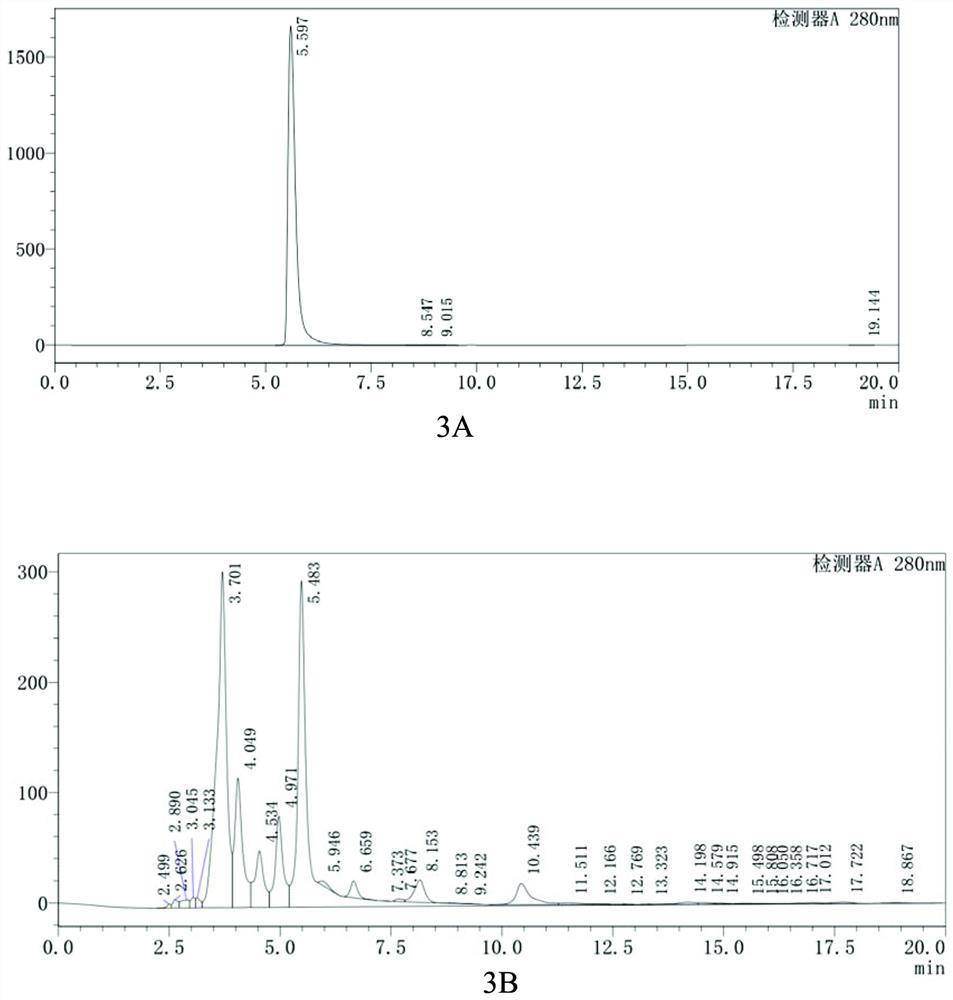

[0045] Application of recombinant Escherichia coli: production of α-arbutin through fermentation and cultivation of recombinant Escherichia coli BW1, BW2, and BW3 respectively

[0046] Pick fresh engineering single colonies of recombinant Escherichia coli BW1, BW2, and BW3 from the plate and inoculate them into 4 mL LB test tubes containing the corresponding antibiotics. After culturing at 37°C for 8 h, transfer them to a shaker containing 50 mL medium containing the corresponding antibiotics. The fermentation culture was carried out in the bottle, the inoculum size was 2%, the fermentation temperature was 30°C or 37°C, and the rotation speed was 200 rpm. Wherein, the medium: 2 g∙L‾ 1 MOPS, 20 g∙L‾ 1 Maltose, 10 g∙L‾ 1 Glycerin, 5 g∙L‾ 1 Yeast powder, 6 g∙L‾ 1 NaHPO 4 , 0.5 g∙L‾ 1 NaCl, 3 g∙L‾ 1 K H 2 PO 4 , 2 g∙L‾ 1 NH 4 Cl, 246.5 mg∙L‾ 1 MgSO 4 , 14.7 mg∙L‾ 1 CaCl 2 , and add corresponding antibiotics according to the actual situation.

[0047] The induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com