Method for growing gallium oxide film through low-pressure chemical vapor deposition

A low-pressure chemical vapor phase and gallium oxide technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve problems such as high cost and complicated operation, and achieve low cost, high light transmittance, and improved The effect of interface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

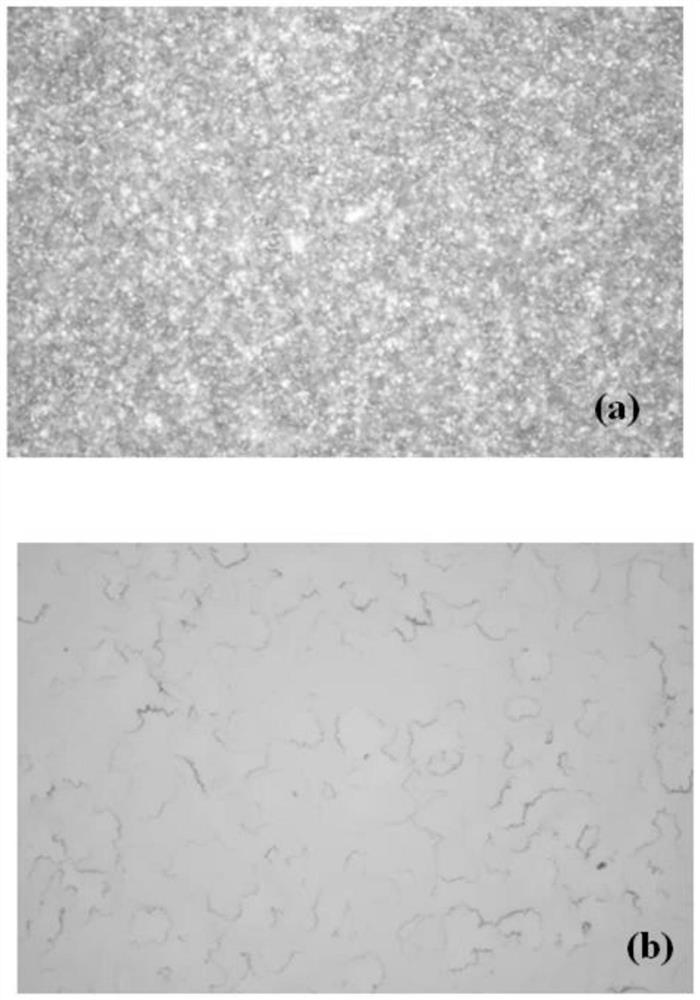

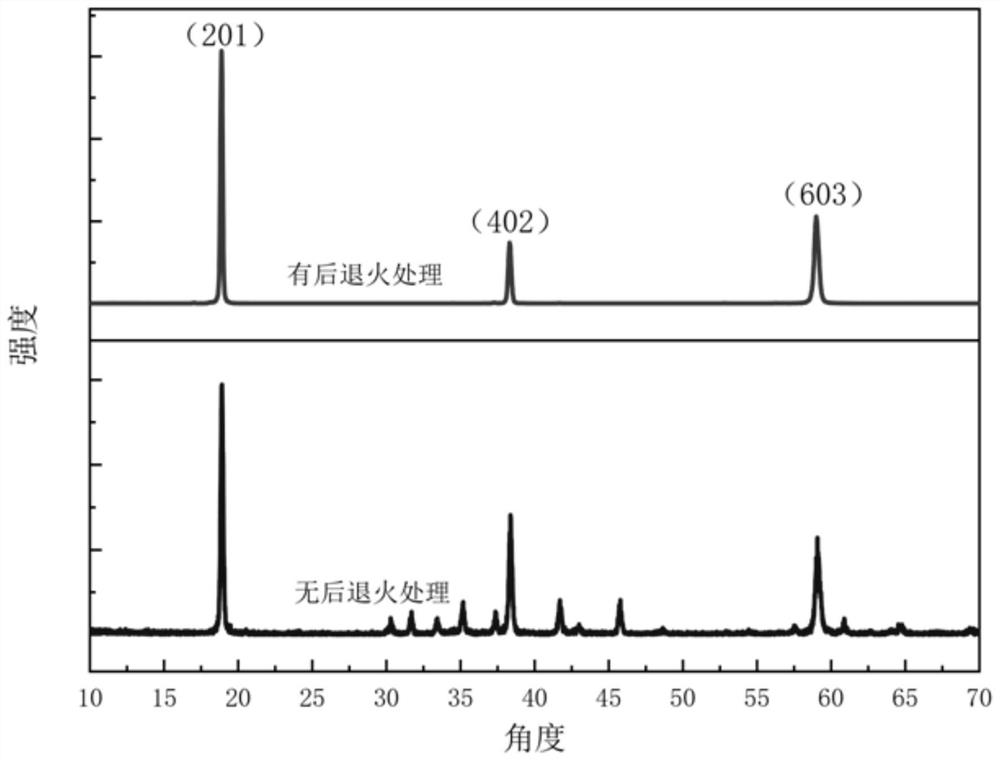

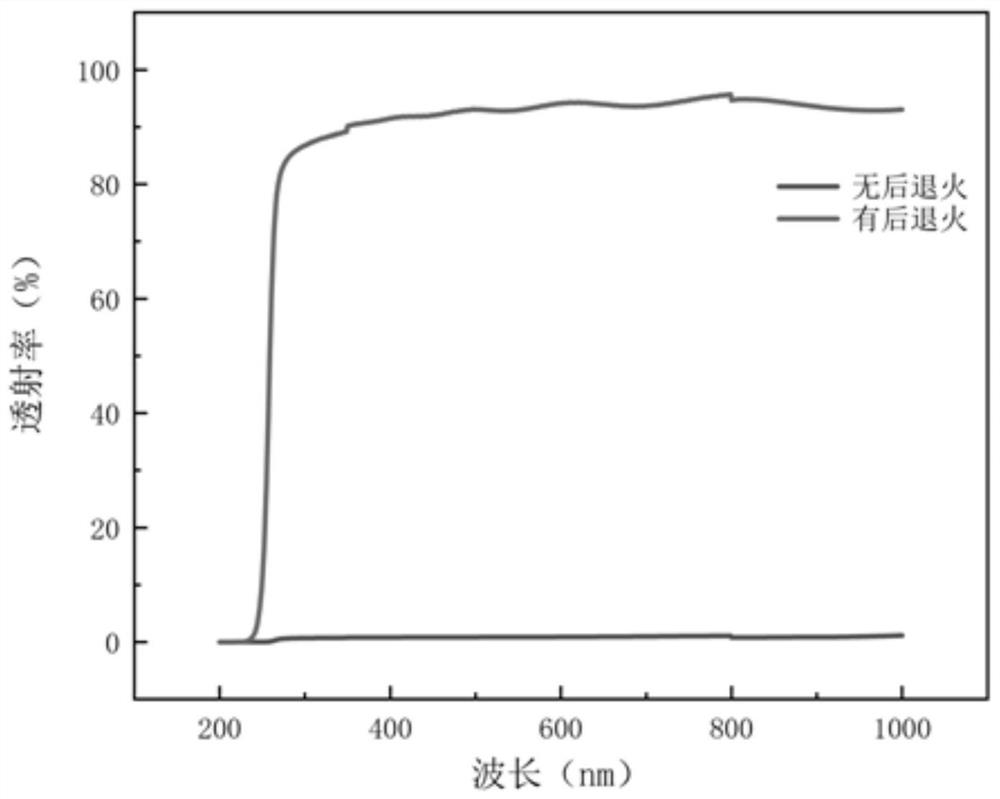

Embodiment 1

[0041] A method for growing a gallium oxide film by low-pressure chemical vapor deposition, the steps comprising the following steps:

[0042] (1) ultrasonically cleaning the substrate with deionized water, acetone and ethanol respectively, and drying for pretreatment to obtain a pretreated substrate;

[0043](2) 0.17g of metal gallium particles are placed in a small crucible, placed on a corundum plate together with the pretreated substrate, and placed in the tube furnace cavity, wherein the substrate is placed horizontally, and the gallium source particles are placed in the The distance between the small crucible and the substrate is 6 cm, and the distance between the gallium source and the edge of the central temperature zone of the tube furnace is 10 cm;

[0044] (3) Seal the tube furnace, evacuate for 30 minutes, and flush the tube furnace cavity 3 times with nitrogen;

[0045] (4) Introduce nitrogen to adjust the pressure in the chamber to 700 Torr, and the nitrogen gas...

Embodiment 2

[0049] A method for growing a gallium oxide film by low-pressure chemical vapor deposition, the steps comprising the following steps:

[0050] (1) ultrasonically cleaning the substrate with deionized water, acetone and ethanol respectively, and drying for pretreatment to obtain a pretreated substrate;

[0051] (2) 0.17g of metal gallium particles are placed in a small crucible, placed on a corundum plate together with the pretreated substrate, and placed in the tube furnace cavity, wherein the substrate is placed horizontally, and the gallium source particles are placed in the The distance between the small crucible and the substrate is 6 cm, and the distance between the gallium source and the edge of the central temperature zone of the tube furnace is 10 cm;

[0052] (3) Seal the tube furnace, evacuate for 30 minutes, and flush the tube furnace cavity 3 times with nitrogen;

[0053] (4) Introduce nitrogen to adjust the pressure in the chamber to 600 Torr, the nitrogen gas fl...

Embodiment 3

[0057] A method for growing a gallium oxide film by low-pressure chemical vapor deposition, the steps comprising the following steps:

[0058] (1) ultrasonically cleaning the substrate with deionized water, acetone and ethanol respectively, and drying for pretreatment to obtain a pretreated substrate;

[0059] (2) 0.17g of metal gallium particles are placed in a small crucible, placed on a corundum plate together with the pretreated substrate, and placed in the tube furnace cavity, wherein the substrate is placed horizontally, and the gallium source particles are placed in the The distance between the small crucible and the substrate is 6 cm, and the distance between the gallium source and the edge of the central temperature zone of the tube furnace is 10 cm;

[0060] (3) Seal the tube furnace, evacuate for 30 minutes, and flush the tube furnace cavity 3 times with nitrogen;

[0061] (4) Introduce nitrogen to adjust the pressure in the chamber to 400 Torr, and the nitrogen ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com