Preparation method of heat-resisting plate for bias plate

A heat-resistant plate and deflector technology, applied in the field of deflectors, can solve the problems of reducing the thermal conductivity of deflectors, reducing the weight of deflectors, and high thermal conductivity, and achieving the effects of reducing maintenance costs, weight, and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

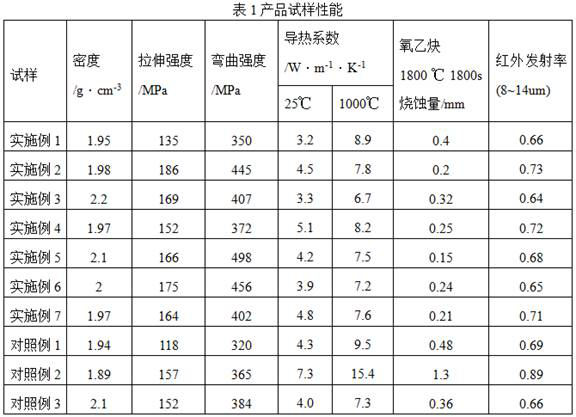

Examples

Embodiment 1

[0049] A method for preparing a heat-resistant plate used for a deflector plate, the steps are as follows:

[0050] (1) Processing carbon fiber prefabricated body: choose 2.5D thin edge puncture to make the density of 0.5g / cm 3 The carbon fiber prefabricated body; the carbon fiber prefabricated body is processed into a prefabricated body with the same shape as the final heat-resistant plate product and a large margin in size;

[0051] (2) CVI deposited pyrolytic carbon interface layer: clamp and fix the preform obtained in step (1) with a graphite mold designed according to the structure of the preform, put the preform with the mold into the CVI deposition furnace, and evacuate to The vacuum degree in the furnace is 100Pa, then the temperature is raised to 1000°C, and then the carbon source gas propane is introduced at a flow rate of 10L / min, the pressure in the furnace is controlled at 5kPa, and the temperature is kept for 25h; Naturally cool down to room temperature under a...

Embodiment 2

[0071] A method for preparing a heat-resistant plate used for a deflector plate, the steps are as follows:

[0072] (1) Processing carbon fiber prefabricated body: choose 2.5D0° / 90° no-weft lamination / net tire needle punching to obtain a density of 0.55g / cm 3 The carbon fiber prefabricated body; the carbon fiber prefabricated body is processed into a prefabricated body with the same shape as the final heat-resistant plate product and a large margin in size;

[0073] (2) CVI deposited pyrolytic carbon interface layer: clamp and fix the preform obtained in step (1) with a graphite mold designed according to the structure of the preform, put the preform with the mold into the CVI deposition furnace, and evacuate to The vacuum degree in the furnace is 100Pa, and then the temperature is raised to 1300°C, and then the carbon source gas methane is introduced at a flow rate of 15L / min, the pressure in the furnace is controlled at 13kPa, and the temperature is kept for 50h; Naturally ...

Embodiment 3

[0094] A method for preparing a heat-resistant plate used for a deflector plate, the steps are as follows:

[0095] (1) Processing carbon fiber prefabricated body: use 3D carbon fiber weaving and molding to obtain a density of 0.45g / cm 3 The carbon fiber prefabricated body; the carbon fiber prefabricated body is processed into a prefabricated body with the same shape as the final heat-resistant plate product and a large margin in size;

[0096] (2) CVI deposited pyrolytic carbon interface layer: clamp and fix the preform obtained in step (1) with a graphite mold designed according to the structure of the preform, put the preform with the mold into the CVI deposition furnace, and evacuate to The vacuum degree in the furnace is 200Pa, and then the temperature is raised to 1070°C, and then the carbon source gas natural gas is introduced at a flow rate of 12L / min, the pressure in the furnace is controlled at 12kPa, and the temperature is maintained for 50h; Naturally cool down to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com