Preparation method of high-purity 1-butene

A high-purity butene technology, applied in the field of olefin polymerization, can solve problems such as reduced catalytic activity and unbalanced mixing ratio, and achieve the effects of reduced processing costs, high selectivity, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of high-purity 1-butene product, comprises the following steps:

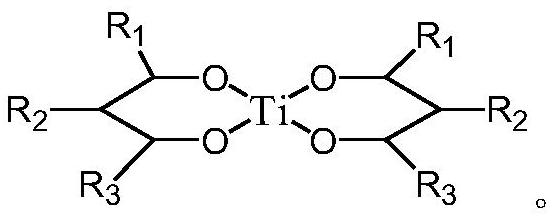

[0028] Under anhydrous and oxygen-free conditions, the titanium source with a Ti-O bicyclic structure and the alkylaluminum are separately prepared in a fixed ratio, dissolved in a solvent, and the molar ratio of the catalyst titanium source to the alkylaluminum co-catalyst is 1:0.5 In the range of ~10, the reaction solvent needs to be dehydrated in advance to ensure that the water content is lower than 10ppm.

[0029] After replacing the heat of the ethylene polymerization reactor, add the solvent, raise it to a certain temperature and pressure, then add the prepared binary catalyst, control the reaction temperature during the reaction, and continuously replenish ethylene to ensure a stable reaction temperature and pressure. The preferred reaction pressure is 1MPa, 1.5MPa, 2.0MPa, 2.5MPa, 3.0MPa, 3.5MPa; the preferred reaction temperature is 30°C, 35°C,...

Embodiment 1

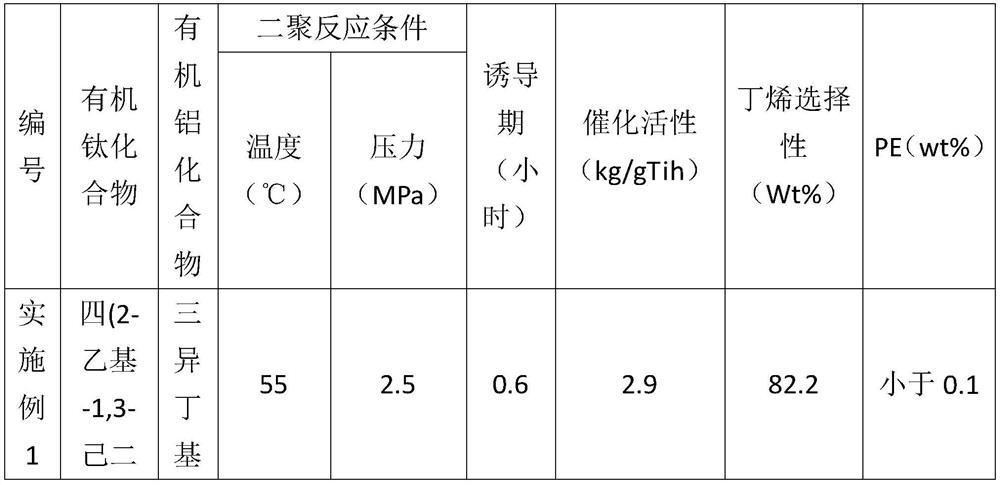

[0035] Heat the alkane solvent to 130°C to clean the high-pressure reactor, and then vacuumize at 110°C after discharging to ensure that the reactor is completely dry, then cool the reactor to 60°C, and replace the gas in the reactor with high-purity nitrogen for 3 Then use ethylene gas to evacuate several times, add 200ml of heptane solvent into the reactor, maintain the system temperature to 50°C, and select tetrakis(2-ethyl-1,3-hexanediol)titanium as catalyst titanium source (Ti[OCH 2 CHCH 2 CH 3 CHCH 2 CH 2 CH 3 O] 2 ), cocatalyst triisobutylaluminum, titanium / aluminum ratio of 1:5, after reacting for 5 hours at 2.5MPa and 55°C, the products in the reactor were collected and analyzed by gas chromatography. The results are shown in Table 1.

Embodiment 2

[0037] Heat the alkane solvent to 130°C to clean the high-pressure reactor, and then vacuumize at 110°C after discharging to ensure that the reactor is completely dry, then cool the reactor to 60°C, and replace the gas in the reactor with high-purity nitrogen for 3 Then use ethylene gas to evacuate several times, add 200ml of hexane solvent into the reactor, maintain the system temperature to 45°C, select tetrakis(2-ethyl-1,3-hexanediol)titanium as catalyst titanium source (Ti[OCH 2 CHCH 2 CH 3 CHCH 2 CH 2 CH 3 O] 2 ), cocatalyst triethylaluminum, titanium / aluminum ratio of 1:5, reacted at 2.5MPa, 50°C for 4 hours, collected the products in the reactor, and analyzed the composition by gas chromatography, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com