Preparation method of a composite oxide dry gel

A composite oxide and oxide technology, which is applied in the preparation of composite oxide dry glue, can solve the problems of rapid precipitation of zirconia or titanium oxide, affecting the physical properties and surface properties of the carrier, and different particle sizes, and achieves a large pore volume. , easy to restore, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

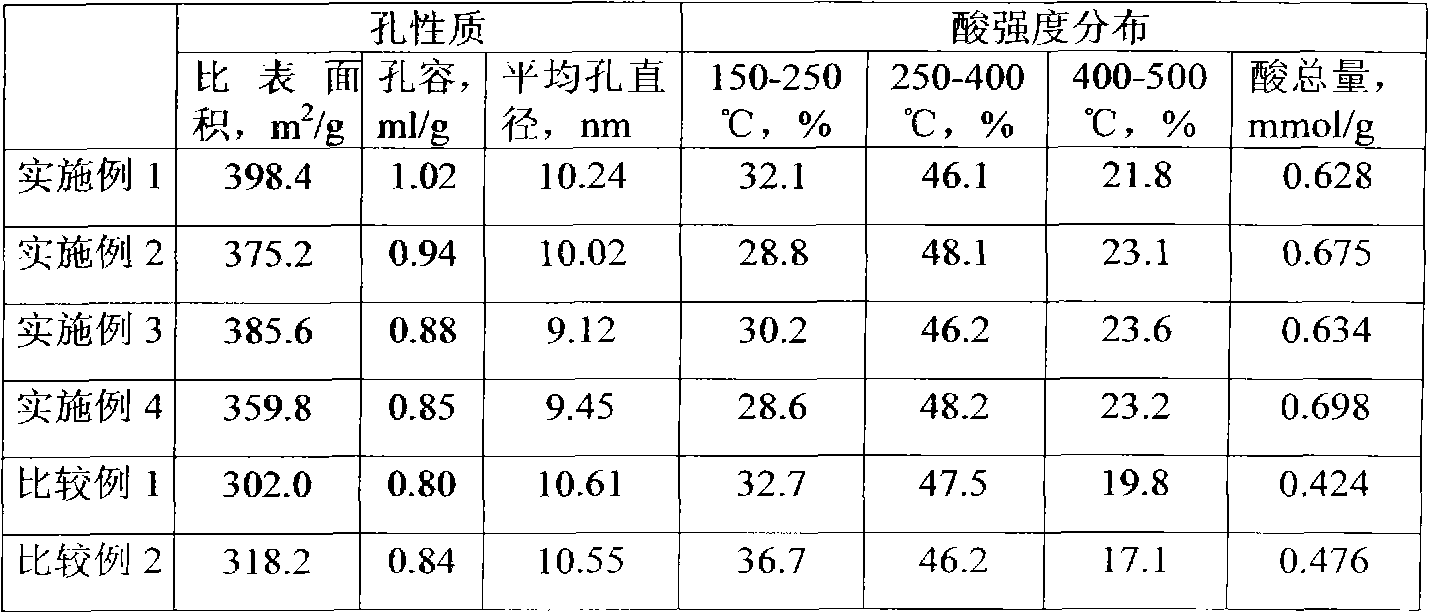

Embodiment 1

[0030] Mix 1000ml 2mol / L aluminum nitrate with 22ml silica gel (containing SiO 2 25wt%), mixed with ammonia water, adjusted to a pH value of 8.5, and reacted at 60° C., and the resulting precipitate was washed and filtered to obtain a wet filter cake. 10g / 100ml of Zr(NO 3 ) 4 The solution is mixed with a theoretical amount of ammonium tartrate to obtain a complex solution. The wet filter cake was added into the complex solution and stirred vigorously, heated to 40°C for aging for 2 hours, suction filtered, and the filter cake was dried at 120°C for 3 hours and pulverized to obtain a composite oxide dry glue. The composite oxide dry glue was calcined at 600°C for 3 hours to obtain a composite oxide, in which the content of zirconia was 10 wt%, and the content of silicon oxide was 5 wt%. The main properties are listed in Table 1.

[0031] Take 131g of composite oxide dry glue, 13.9g of SB powder, add 3g of scallop powder, 5ml of dilute nitric acid, knead, extrude, dry at 120°...

Embodiment 2

[0033] Mix 1 mol / L aluminum sulfate and 1 mol / L sodium metaaluminate in parallel, adjust the pH value to 7.0, and react at 50°C. The resulting precipitate is washed and filtered to obtain a wet filter cake. 20g / 100ml of Zr(NO 3 ) 4 The solution is mixed with a theoretical amount of ammonium tartrate to obtain a complex solution. The rest are the same as in Example 1 to obtain the composite oxide dry glue. The composite oxide dry glue was calcined at 600°C for 3 hours to obtain a composite oxide, in which the content of zirconia was 50 wt%, and its main properties are listed in Table 1.

[0034] Take 118g of composite oxide dry glue, 27.8g of SB powder, add 3g of scallop powder, 3ml of dilute nitric acid and 2ml of acetic acid, knead, extrude, dry at 120°C for 3 hours, and roast at 600°C for 3 hours to obtain a composite oxide carrier .

Embodiment 3

[0036] Mix 1000ml 2mol / L aluminum nitrate with 22ml silica gel (containing SiO 2 25 wt%), mixed with ammonia water, adjusted to a pH of 7.5, reacted at 60° C. and aged for 3 hours, and the resulting precipitate was washed and filtered to obtain a wet filter cake. 10g / 100ml of TiCl 4 The solution is mixed with a theoretical amount of EDTA to obtain a complex solution. The wet filter cake was added into the complex solution and stirred vigorously, filtered with suction, and the filter cake was dried at 120° C. for 3 hours and pulverized to obtain the composite oxide dry glue. The composite oxide gel was calcined at 600° C. for 3 hours to obtain a composite oxide, wherein the content of titanium oxide was 10 wt %, and the content of silicon oxide was 5 wt %. The main properties are listed in Table 1.

[0037] Take 141g of composite oxide dry glue, 139g of SB powder, add 3g of scallop powder, 5ml of dilute nitric acid, knead, extrude, dry at 120°C for 3 hours, and roast at 600°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com