Sustained-release carrier, chlorine dioxide gel composition containing sustained-release carrier and application thereof

A slow-release carrier, chlorine dioxide technology, applied in applications, chemicals for biological control, animal repellants, etc., can solve problems such as waste, corrosion of equipment, and inconvenience in use and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

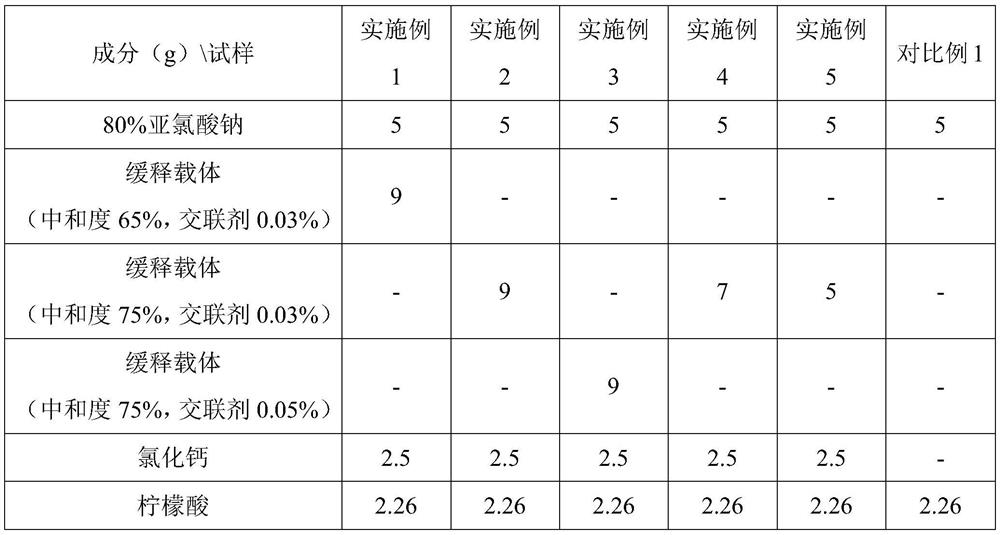

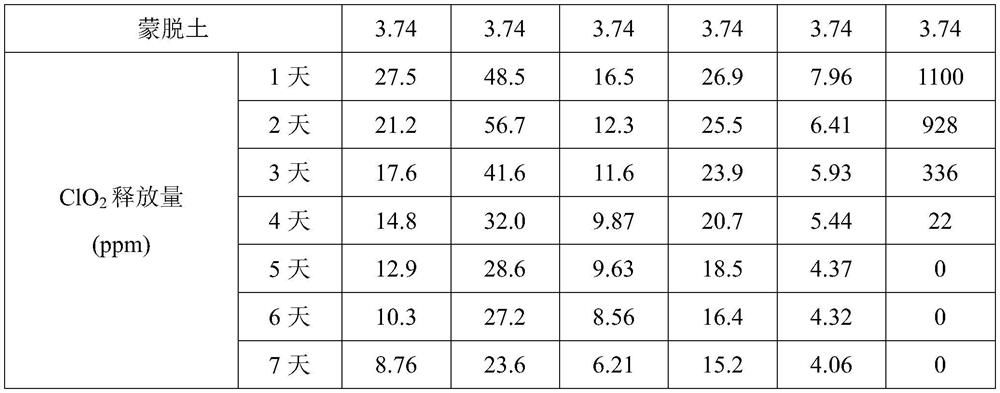

Embodiment 1

[0090] Embodiment 1 A kind of slow-release carrier and its slow-release chlorine dioxide gel composition

[0091] (1) Preparation of slow-release carrier:

[0092] Aqueous solution preparation:

[0093] Under the condition of ice-water bath, titrate 125 parts of acrylic acid aqueous solution (80% concentration) with 25% sodium hydroxide solution to make the neutralization degree of the solution 65%, and then add 0.01 parts of N,N'-methylene Base bisacrylamide, 0.24 parts of potassium persulfate, 0.06 parts of sodium bisulfite, prepared into an aqueous solution.

[0094] Oil phase solution preparation:

[0095] Add 0.3 part of polyoxyethylene alkyl ether phosphate into 600 parts of cyclohexane and dissolve to prepare an oil phase solution.

[0096] Preparation of slow-release carrier:

[0097] Slowly raise the temperature of the oil phase solution to 70°C, drop the water phase solution into the oil phase solution under the condition of nitrogen protection, and continue the ...

Embodiment 2

[0102] Embodiment 2 A slow-release carrier and its slow-release chlorine dioxide gel composition

[0103] (1) Preparation of slow-release carrier:

[0104] Aqueous solution preparation:

[0105] Under the condition of an ice-water bath, titrate 125 parts of acrylic acid aqueous solution (80% concentration) with a 25% sodium hydroxide solution to make the neutralization degree of the solution 75%, and then add 0.01 parts of N,N'-methylene Base bisacrylamide, 0.24 parts of potassium persulfate, 0.06 parts of sodium bisulfite, prepared into an aqueous solution.

[0106] Oil phase solution preparation:

[0107] Add 0.3 part of polyoxyethylene alkyl ether phosphate into 600 parts of cyclohexane and dissolve to prepare an oil phase solution.

[0108] Preparation of slow-release carrier:

[0109]Slowly raise the temperature of the oil phase solution to 70°C, drop the water phase solution into the oil phase solution under the condition of nitrogen protection, and continue the reac...

Embodiment 3

[0115] Embodiment 3 A slow-release carrier and its slow-release chlorine dioxide gel composition

[0116] (1) Preparation of slow-release carrier:

[0117] Aqueous solution preparation:

[0118] Under the condition of an ice-water bath, titrate 125 parts of acrylic acid aqueous solution (80% concentration) with a 25% sodium hydroxide solution to make the neutralization degree of the solution 75%, and then add 0.01 parts of N,N'-methylene Base bisacrylamide, 0.24 parts of potassium persulfate, 0.06 parts of sodium bisulfite, prepared into an aqueous solution.

[0119] Oil phase solution preparation:

[0120] Add 0.3 part of polyoxyethylene alkyl ether phosphate into 600 parts of cyclohexane and dissolve to prepare an oil phase solution.

[0121] Preparation of slow-release carrier:

[0122] Slowly raise the temperature of the oil phase solution to 70°C, drop the water phase solution into the oil phase solution under the condition of nitrogen protection, and continue the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com