Polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, applied in the field of polypropylene composite materials and its preparation, can solve problems such as unsatisfactory performance and unfavorable wave penetration, and achieve the effects of improving strength, expanding material application fields, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

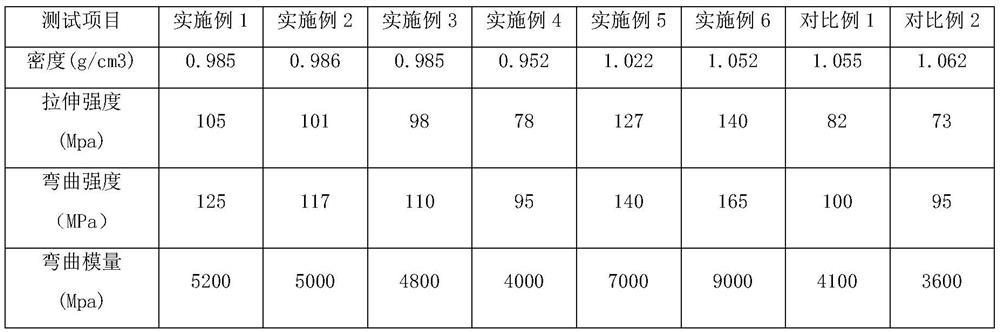

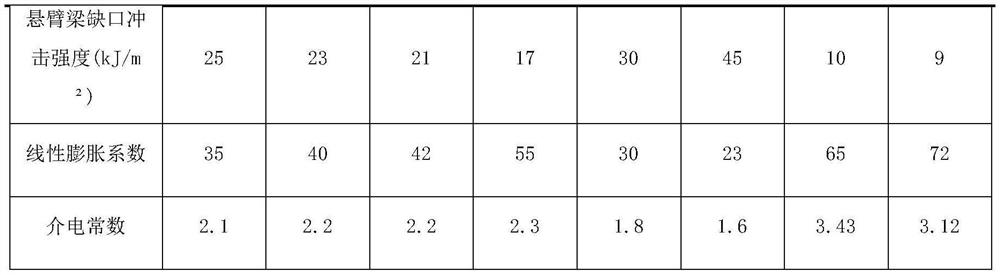

Examples

Embodiment 1

[0024] The preparation method of polypropylene composite material comprises the following steps:

[0025] By weight, weigh 21 parts of high fluidity copolymerized polypropylene resin A; its melt index characteristic value is 90g / 10min;

[0026] 28.5 parts of high fluidity copolymerized polypropylene resin B; its melt index characteristic value is 55g / 10min;

[0027] 21 parts of high-impact copolymerized polypropylene resin C; its characteristic value is 60kJ / ㎡ of notched impact strength at room temperature.

[0028] 5 parts of toughening agent have a melt flow index of 10g / 10min and a density of 0.85g / cm 3 ethylene octene copolymer;

[0029] 20 parts of aluminum titanate whiskers; the whiskers are 0.4 μm in diameter and 16 μm in length;

[0030] The antioxidant SONOX 1010 of 0.4 part and antioxidant SONOX 168; The mass ratio of described antioxidant SONOX 1010 and antioxidant SONOX 168 is 1:2;

[0031] 0.1 part of ethyl bis stearamide EBS;

[0032] 0.3 parts of epoxy resi...

Embodiment 2

[0037] The preparation method of polypropylene composite material comprises the following steps:

[0038] By weight, weigh 21 parts of high fluidity copolymerized polypropylene resin A; its melt index characteristic value is 100g / 10min;

[0039] 28.5 parts of high fluidity copolymerized polypropylene resin B; its melt index characteristic value is 60g / 10min;

[0040] 21 parts of high-impact copolymerized polypropylene resin C; its characteristic value is 40kJ / ㎡ of notched impact strength at room temperature.

[0041] 5 parts of toughening agent have a melt flow index of 15g / 10min and a density of 0.9g / cm 3 ethylene butene copolymer;

[0042] 20 parts of sodium titanate whiskers, the whiskers are 0.6 μm in diameter and 20 μm in length;

[0043] The antioxidant SONOX 168 of 0.4 part and antioxidant SONOX 1076, the mass ratio of described antioxidant SONOX 168 and antioxidant SONOX 1076 is 1:3;

[0044] 0.1 part of STRUKTOL TR451;

[0045] 0.3 parts light stabilizer is T-81....

Embodiment 3

[0050] The preparation method of polypropylene composite material comprises the following steps:

[0051] By weight, weigh 21 parts of high fluidity copolymerized polypropylene resin A; its melt index characteristic value is 80g / 10min;

[0052]28.5 parts of high fluidity copolymerized polypropylene resin B; its melt index characteristic value is 50g / 10min;

[0053] 21 parts of high-impact copolymerized polypropylene resin C; its characteristic value is 50kJ / ㎡ of notched impact strength at room temperature.

[0054] The 5 parts of toughening agent have a melt flow index of 0.5g / 10min and a density of 0.8g / cm 3 The ethylene octene copolymer and ethylene butene copolymer; Wherein the mass ratio of ethylene octene copolymer and ethylene butene copolymer is 1:1;

[0055] 20 parts of potassium titanate whiskers, the whiskers are 0.1 μm in diameter and 3 μm in length;

[0056] The antioxidant SONOX 168 of 0.4 part and antioxidant DLTDP, the mass ratio of described antioxidant SONO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com