Graphene heating film prepared through water transfer printing and preparation method of graphene heating film

An alkene heating film and water transfer printing technology, applied in the field of graphene, can solve the problems of poor coating uniformity affecting heating uniformity, etc., and achieve good heating effect, good heating uniformity, and good heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

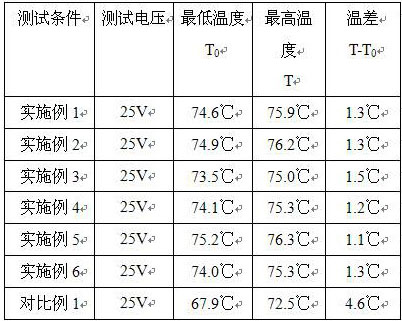

Examples

Embodiment 1

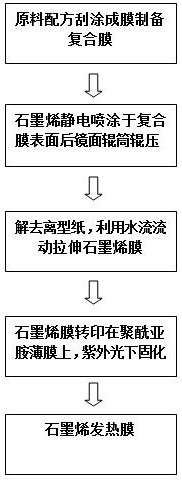

[0035] A preparation method for preparing graphene heating film by water transfer printing, comprising the steps of:

[0036] Step 1. Disperse the high-viscosity photocurable resin aliphatic modified epoxy acrylate and curing agent evenly in a high-speed mixer, and then scrape the obtained compound on the release paper coated with polytetrafluoroethylene emulsion Form a film to obtain a composite film; the aliphatic modified epoxy acrylate is an aliphatic modified epoxy diacrylate with a viscosity of 4000mpa·s at 40°C; the curing agent is a photoinitiator TPO; Scrape coating is used to form a film with a coating machine, the coating speed is 120m / min, and the coating thickness is 0.3mm; the size of the release paper is 900mm×600mm, and the thickness is 0.3mm. 0.05mm thick polytetrafluoroethylene emulsion;

[0037] Wherein, each raw material is calculated by weight, 45 parts of aliphatic modified epoxy acrylate, 2 parts of curing agent;

[0038] Step 2, electrostatically spra...

Embodiment 2

[0043] A preparation method for preparing graphene heating film by water transfer printing, comprising the steps of:

[0044] Step 1. Disperse the high-viscosity photocurable resin aliphatic modified epoxy acrylate and curing agent evenly in a high-speed mixer, and then scrape the obtained compound on the release paper coated with polytetrafluoroethylene emulsion Form a film to obtain a composite film; the aliphatic modified epoxy acrylate is an aliphatic modified epoxy diacrylate with a viscosity of 4000mpa·s at 40°C; the curing agent is a photoinitiator TPO; Scrape coating is used to form a film with a coating machine, the coating speed is 120m / min, and the coating thickness is 0.1mm; the size of the release paper is 900mm×600mm, the thickness is 0.3mm, and the thickness is coated on the release paper 0.01 thick polytetrafluoroethylene emulsion;

[0045] Wherein, each raw material is calculated by weight, 40 parts of aliphatic modified epoxy acrylate, 3 parts of curing agen...

Embodiment 3

[0051] A preparation method for preparing graphene heating film by water transfer printing, comprising the steps of:

[0052] Step 1. Disperse the high-viscosity photocurable resin aliphatic modified epoxy acrylate and curing agent evenly in a high-speed mixer, and then scrape the obtained compound on the release paper coated with polytetrafluoroethylene emulsion Form a film to obtain a composite film; the aliphatic modified epoxy acrylate is an aliphatic modified epoxy diacrylate with a viscosity of 4000mpa·s at 40°C; the curing agent is a photoinitiator TPO; Scrape coating is used to form a film with a coating machine, the coating speed is 120m / min, and the coating thickness is 0.4mm; the size of the release paper is 900mm×600mm, the thickness is 0.3mm, and the thickness is coated on the release paper 0.03mm thick polytetrafluoroethylene emulsion;

[0053] Wherein, each raw material is calculated by weight, 40 parts of aliphatic modified epoxy acrylate, 2 parts of curing ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com