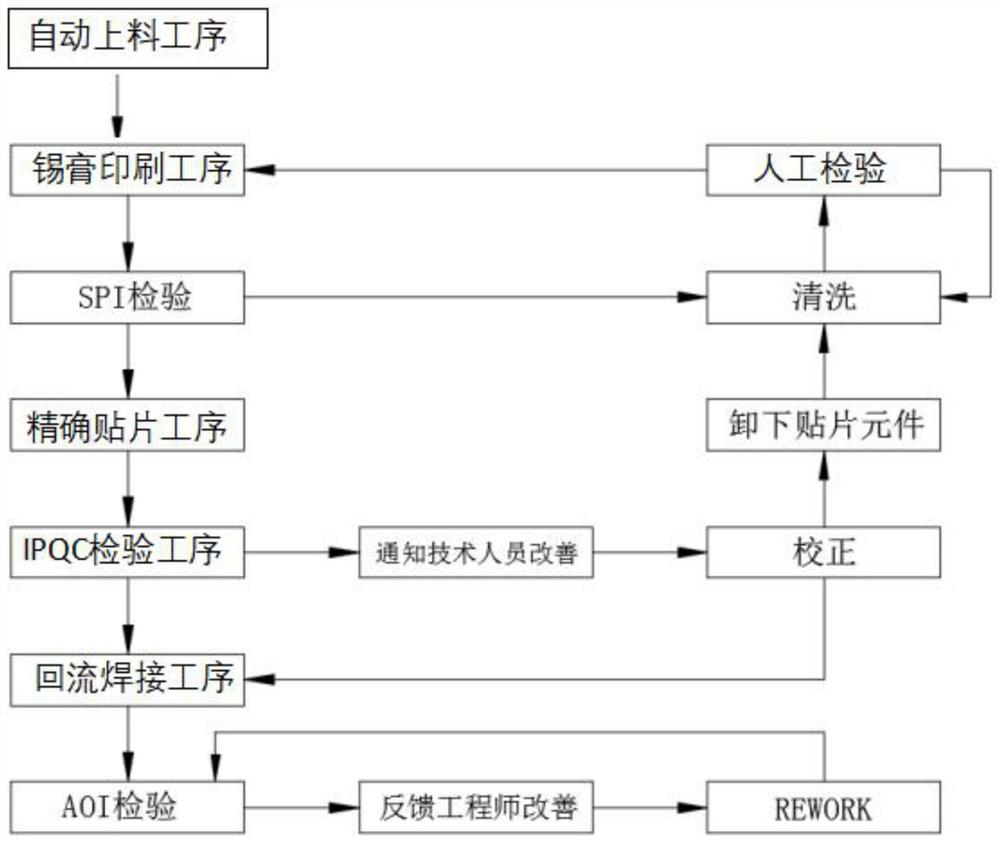

PCB tin brushing patch production process method

A production process and tin patch technology, which is applied in the field of PCB tin patch production process, can solve the problems of low production efficiency and high defect rate, and achieve the effects of improved production efficiency, good wetting, and large spreading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

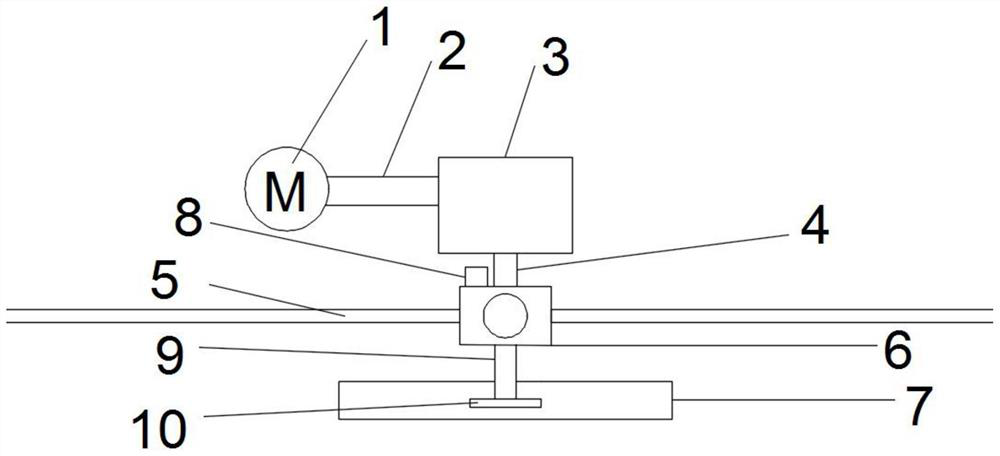

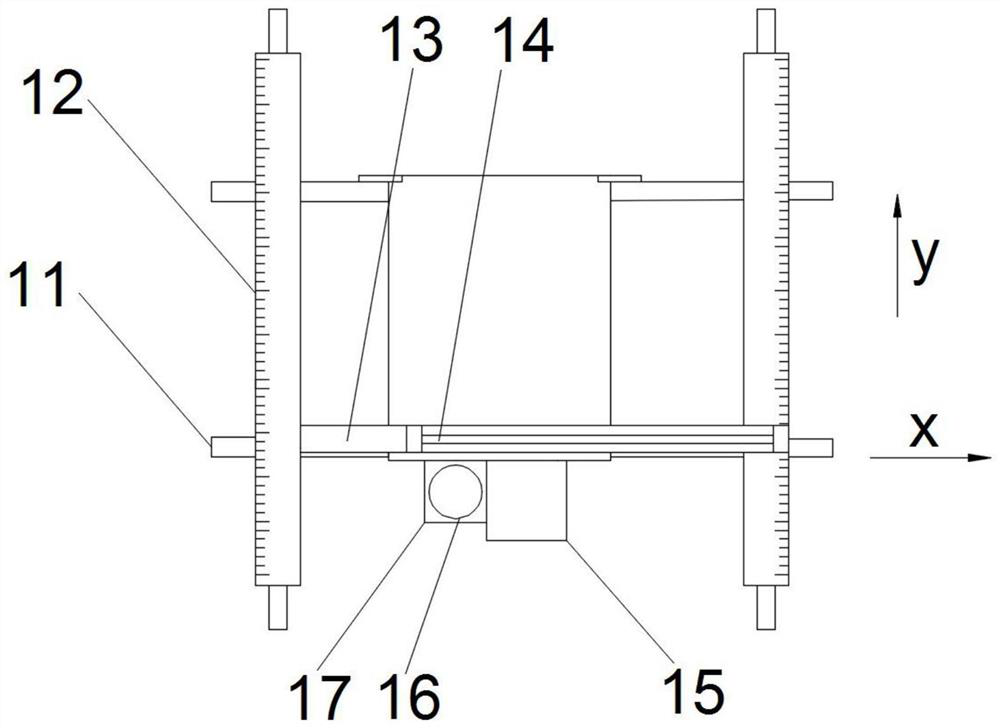

Method used

Image

Examples

Embodiment 1

[0043] Example 1: The solder paste formula is Sn-Bi lead-free solder paste. The specific formula is a combination of metal powder and flux, according to the weight ratio: 88% metal powder, 12% flux; wherein the metal powder is: Sn: 42%, Bi: 57%, Ag: 1%, flux is composed of activator, solvent, thixotropic agent and film former, active agent 8-9%, solvent 5-11.5%, thixotropic agent 0.5-1% And film former 80-85%. According to weight ratio: active agent 9%, solvent 8.4%, thixotropic agent 1% and film former 81.6%, wherein the selected active agent is methyl succinic acid, adipic acid, salicylic acid and succinic acid by weight The ratio is 5:3:5:2, and organic amines are added to adjust the pH at room temperature or low temperature. Among them, triethanolamine is selected as the organic amine.

[0044] The solvent is selected from ethylene glycol ethyl ether, tetrahydrofurfuryl alcohol, and diethylene glycol ethyl ether, and the compounding ratio is 1:2:2 by weight. The thixotro...

Embodiment 2

[0045] Example 2 The solder paste formula is Sn-Bi lead-free solder paste. The specific formula is a combination of metal powder and flux, according to the weight ratio: metal powder 88%, flux 12%; wherein the metal powder is according to the weight ratio: Sn: 42 %, Bi: 57%, Ag: 1%, flux is composed of activator, solvent, thixotropic agent and film-forming agent, active agent 8-9%, solvent 5-11.5%, thixotropic agent 0.5-1% and Film former 80-85%. According to weight ratio: active agent 9%, solvent 8.4%, thixotropic agent 1% and film former 81.6%, wherein the selected active agent is methyl succinic acid, adipic acid, salicylic acid and succinic acid by weight The ratio is 5:3:5:2, and organic amines are added to adjust the pH at room temperature or low temperature. Among them, triethanolamine is selected as the organic amine.

[0046] The solvent is selected from ethylene glycol ethyl ether, tetrahydrofurfuryl alcohol, and diethylene glycol ethyl ether, and the compounding ra...

Embodiment 3

[0047] Example 3 The solder paste formula is Sn-Bi series lead-free solder paste. The specific formula is a combination of metal powder and flux, according to the weight ratio: 80% metal powder, 20% flux; wherein the metal powder according to the weight ratio is: Sn: 42 %, Bi: 57%, Ag: 1%, flux is composed of activator, solvent, thixotropic agent and film-forming agent, active agent 8-9%, solvent 5-11.5%, thixotropic agent 0.5-1% and Film former 80-85%. According to weight ratio: active agent 9%, solvent 8.4%, thixotropic agent 1% and film former 81.6%, wherein the selected active agent is methyl succinic acid, adipic acid, salicylic acid and succinic acid by weight The ratio is 5:3:5:2, and organic amines are added to adjust the pH at room temperature or low temperature, among which triethanolamine is selected as the organic amine.

[0048] The solvent is a mixture of ethylene glycol ether, tetrahydrofurfuryl alcohol, and diethylene glycol ether, and the compounding ratio is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com