Catalyst for improving content of cycloalkane in tar through microwave pyrolysis of low-rank coal as well as preparation method and application of catalyst

A low-rank coal and cycloalkane technology, applied in the field of microwave catalytic pyrolysis of low-rank coal, can solve the problems of catalyst deactivation, unfavorable tar formation, and high price of molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

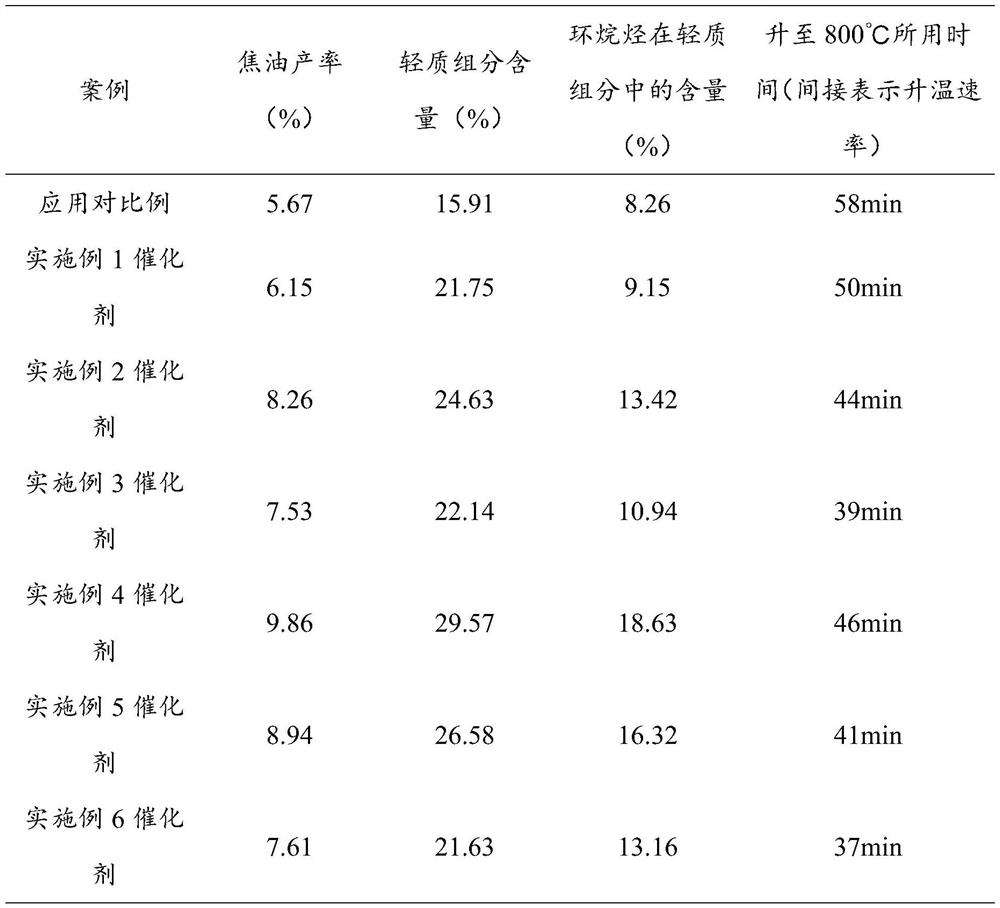

Examples

preparation example Construction

[0039] The present invention provides a method for preparing a catalyst for increasing the content of naphthenes in tar by microwave pyrolysis of low-rank coal described in the above technical solution, comprising the following steps:

[0040] mixing the metal salt corresponding to the catalytically active substance and the metal salt corresponding to the cocatalyst with water to obtain a metal salt solution;

[0041] mixing the metal salt solution with an aqueous solution of sodium dodecylbenzenesulfonate, adjusting the pH value to 9-10 to obtain a suspension;

[0042] The suspension is separated, and the obtained solid deposit is first calcined to obtain a nanocatalyst precursor;

[0043] The nano-catalyst precursor is mixed with the catalyst carrier and the dispersant, and dispersed, and the resulting dispersion is subjected to microwave irradiation and second roasting in sequence to obtain a catalyst for increasing the content of cycloalkane in tar by microwave pyrolysis o...

Embodiment 1

[0087]2.9081g (0.01mol) Ni(NO 3 ) 2 ·6H 2 O, 1.2080g (0.005mol) Cu(NO 3 ) 2 ·3H 2 O was added to 100mL of deionized water, stirred until completely dissolved to obtain a metal salt solution, dissolved in 100mL of deionized water with 0.1163g of sodium dodecylbenzenesulfonate and stirred until completely dissolved to obtain an aqueous solution of sodium dodecylbenzenesulfonate (1.163g / L), the metal salt solution and the sodium dodecylbenzenesulfonate aqueous solution are stirred and mixed evenly at 80°C, and 3mol / L potassium hydroxide solution is added dropwise in the resulting mixed solution to adjust the pH =10, continuously stirred at 200rpm at 80°C for 2h to obtain a suspension, centrifuged the suspension, washed the obtained solid product with deionized water and ethanol repeatedly, and suction filtered until pH=7, Put the obtained solid deposit into an oven at 110°C for 2 hours, cool it to room temperature, put it into a muffle furnace and raise the temperature to 60...

Embodiment 2

[0090] 2.9081g Ni(NO 3 ) 2 ·6H 2 O, 2.4160g Cu(NO 3 ) 2 ·3H 2 O was added to 100mL of deionized water, stirred until completely dissolved to obtain a metal salt solution, dissolved in 100mL of deionized water with 0.1163g of sodium dodecylbenzenesulfonate and stirred until completely dissolved to obtain an aqueous solution of sodium dodecylbenzenesulfonate (1.163g / L), the metal salt solution and the sodium dodecylbenzenesulfonate aqueous solution are stirred and mixed evenly at 80°C, and 3mol / L potassium hydroxide solution is added dropwise in the resulting mixed solution to adjust the pH =10, continuously stirred at 200rpm at 80°C for 2h to obtain a suspension, centrifuged the suspension, washed the obtained solid product with deionized water and ethanol repeatedly, and suction filtered until pH=7, Put the obtained solid deposit into an oven at 110°C for 2 hours, cool it to room temperature, put it into a muffle furnace and raise the temperature to 600°C at 5°C / min, perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com