Two-end alkyl-terminated PAG polyether and preparation method thereof

An alkyl-terminated, polyether technology, used in manufacturing tools, heat treatment equipment, quenching agents, etc., can solve the problems of oxidation resistance, stability, influence of quenching performance, reduce corrosion resistance of quenching liquid system, etc. Corrosion resistance, excellent hardenability, low foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the first aspect, the present application provides a method for preparing PAG polyether terminated by alkyl groups at both ends, characterized in that the preparation method comprises the following steps:

[0040] S1: Under an inert atmosphere and in the presence of a catalyst, react the polyol initiator with the first part of ethylene oxide and the first part of propylene oxide at a reaction temperature of 120-130°C and a reaction pressure of 0-0.3Mpa Random copolymerization is carried out under the following conditions to obtain the first PAG polyether intermediate terminated by an alkyl group at both ends;

[0041] S2: Under an inert atmosphere and in the presence of a catalyst, make the first two-end alkyl-terminated PAG polyether intermediate and the second part of ethylene oxide and the second part of propylene oxide be at a temperature of 100 to 110 The random copolymerization is carried out under the reaction temperature of ℃ and the reaction pressure of 0-0....

Embodiment 1

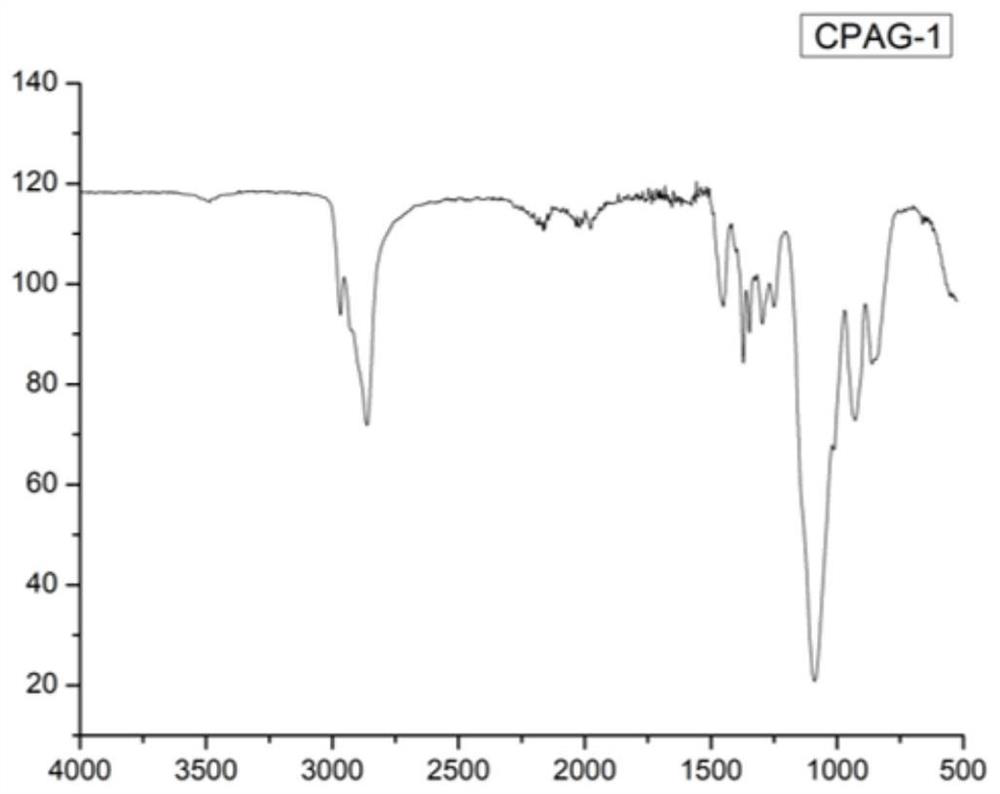

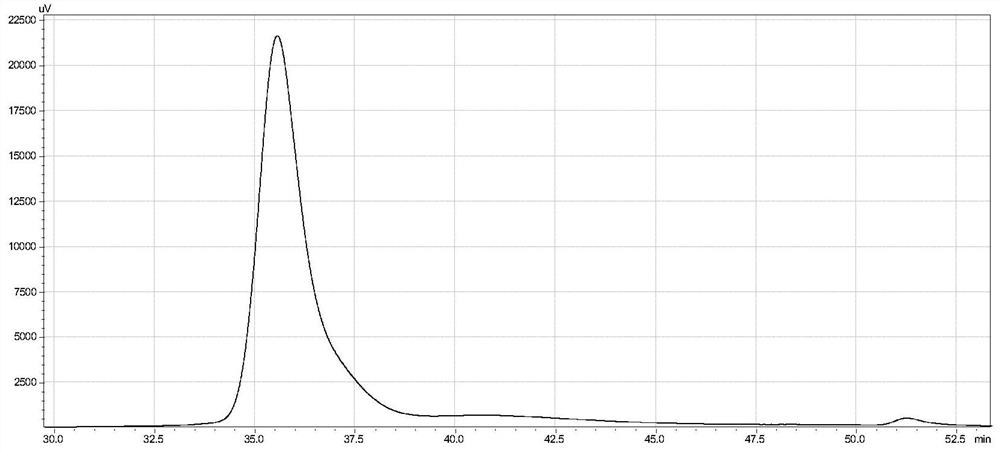

[0068] This example relates to the synthesis of PAG polyether CPAG-1 terminated by alkyl groups at both ends.

[0069] 1. Preparation of intermediate PAG-1 polyether

[0070] (1) Add 20g of glycerin and 2.17g of potassium methoxide catalyst into a dry and well-sealed reaction kettle, replace with positive and negative nitrogen pressure three times, raise the temperature to 80-85°C for dehydration with nitrogen for 1 hour, add dropwise 740.5g of ethylene oxide, 325.4g of propylene oxide mixture was reacted at a reaction temperature of 120-130°C and a pressure of 0-0.3Mpa. After the dropwise addition was completed, the temperature was maintained for 2 hours, degassed for 30 minutes, and finally cooled to 60°C for discharge;

[0071] (2) Add 100g of the finished product synthesized in the above (1) and 0.5g of potassium hydride catalyst into a dry and well-sealed reaction kettle, replace the positive and negative pressure of nitrogen three times, raise the temperature to 110-120°C ...

Embodiment 2

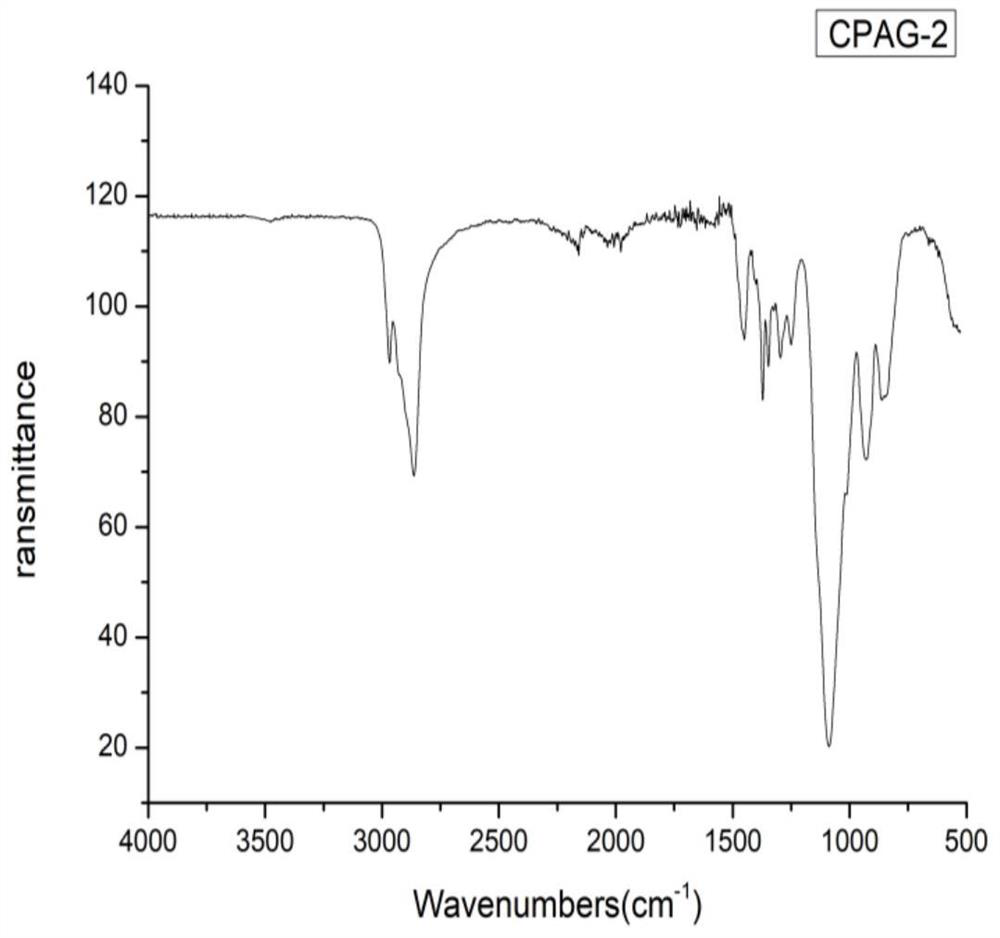

[0075] This example relates to the synthesis of both ends of the alkyl terminated PAG polyether CPAG-2.

[0076] 1. Preparation of intermediate PAG-2 polyether

[0077] (1) Add 20g of diethylene glycol and 1.88g of potassium methoxide catalyst into a dry and well-sealed reaction kettle, replace it with positive and negative nitrogen pressure three times, raise the temperature to 80-85°C for dehydration with nitrogen blowing for 1 hour, and add 692g of ethylene oxide dropwise , 231g of propylene oxide mixture was reacted at a reaction temperature of 120-130°C and a pressure of 0-0.3Mpa. After the dropwise addition was completed, the temperature was maintained for 2 hours, degassed for 30 minutes, and finally cooled to 60°C for discharge;

[0078] (2) Add 100g of the finished product synthesized in the above (1) and 0.45g of potassium hydride catalyst into a dry and well-sealed reaction kettle, replace the positive and negative pressure of nitrogen three times, raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com