Anaerobic adhesive as well as preparation method and application thereof

A technology of anaerobic adhesives and adhesives, applied in the field of anaerobic adhesives, can solve problems such as difficult to meet the basic performance requirements, affect the physical and mental health of personnel, and peeling of users, and achieve good rubber flexibility, good sealing performance, and penetration speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of Accelerator A: In molar parts, add 1 part of 4-butyl phthaloylsulfonimide to 25 parts of ethanol, slowly add 1.1 parts of quinoline while stirring at room temperature, continue stirring for 3 hours after the addition, and then After standing at 5°C for 5 hours, crystallization was observed, the filter residue was collected by filtration, and the filter residue was distilled under reduced pressure to obtain a crystal salt which was Accelerator A.

[0036] The preparation of the anaerobic adhesive, in parts by weight, sequentially add 47 parts by weight of ethoxylated bisphenol A dimethacrylate, 21 parts by weight of ethylene glycol dimethacrylate, and polyurethane methyl 30 parts by weight of acrylate, the rotating speed is adjusted to 750r / min, and stirred until completely dissolved;

[0037] Then add 0.09 parts by weight of naphthoquinone in the stirrer, and stir for 30-40min;

[0038] Add 1.2 parts by weight of accelerator A, 0.05 parts by weight of as...

Embodiment 2-10

[0051] The preparation methods of Examples 2-10 and Comparative Examples 1-2 are the same as Example 1.

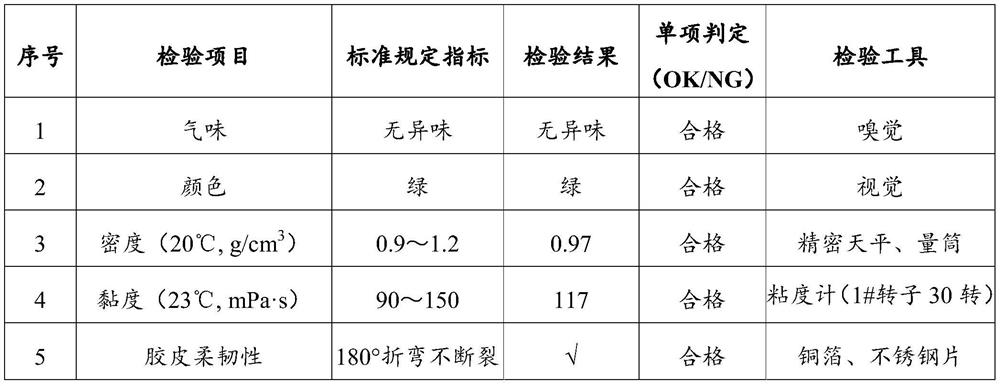

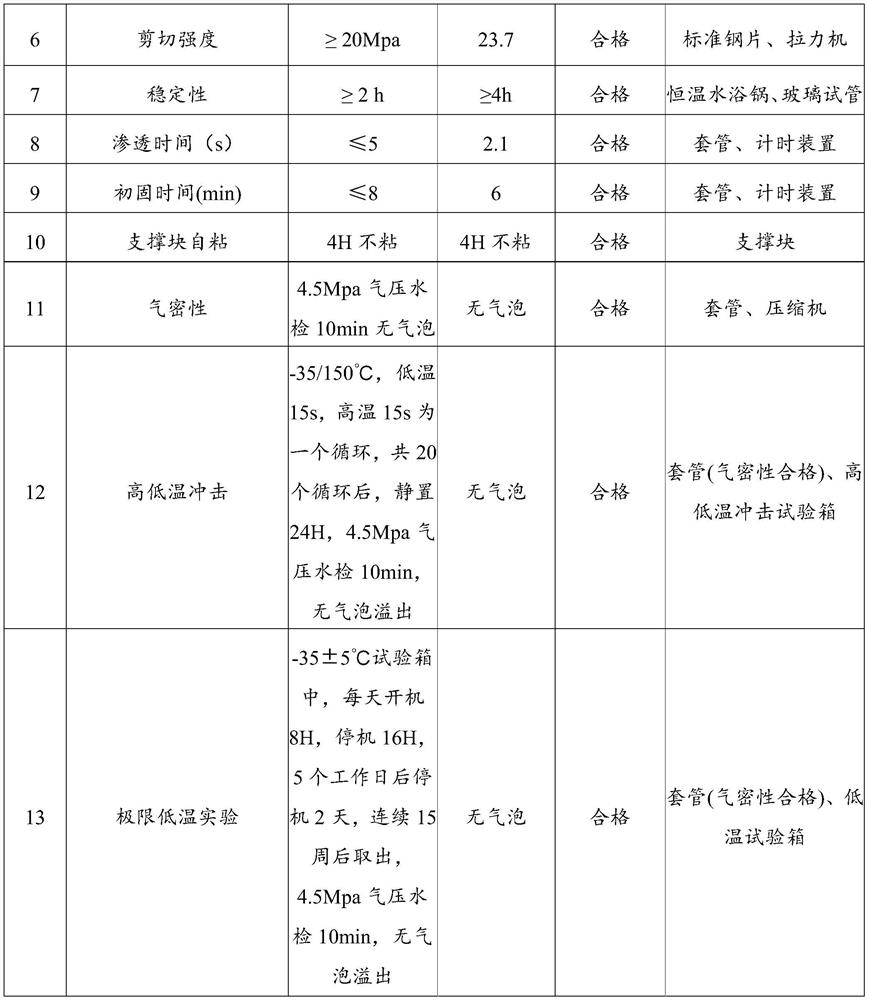

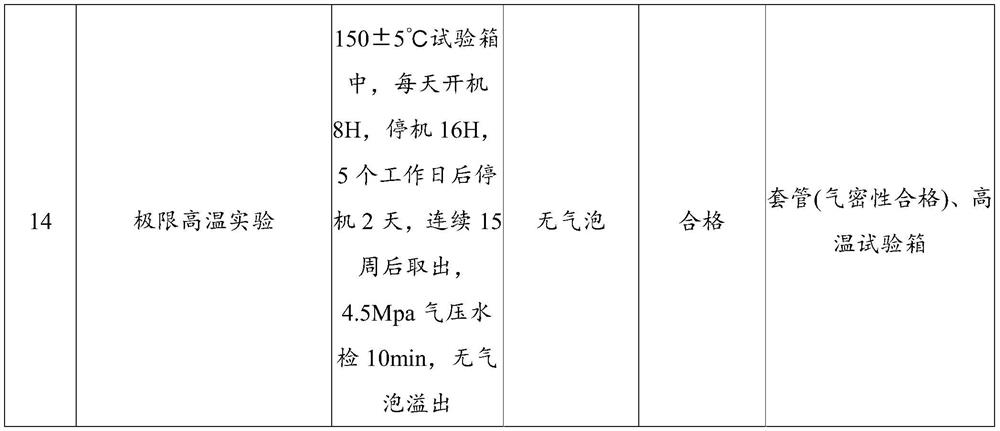

[0052]To embodiment 1-10, initial solidification time and shear strength of comparative example 1-2 are tested, and test result is as shown in table 3:

[0053] Table 3. Embodiment 1-10, initial solidification time and shear strength detection result of comparative example 1-2

[0054]

[0055]

[0056] According to Table 3, it can be seen that after 48 hours, the anaerobic adhesives of Examples 1-10 and Comparative Examples 1-2 have been completely cured, and the shear strength will not increase significantly. The shear strength is mainly determined by the film-forming resin and reactive monomer, and the whole initiating system has little influence on it. It can be seen from Table 3 that after the adhesive is completely cured, the overall shear strength is not much different. The shear strength of Example 1-10 is slightly higher than that of Comparative Example 1-2...

Embodiment 11

[0063] Preparation of Accelerator A: In terms of molar parts, add 1 part of bisbenzenesulfonimide to 30 parts of ethanol, slowly add 1.2 parts of isoquinoline while stirring at room temperature, continue stirring for 4 hours after the addition, and then at 8 ° C After standing still for 6 hours, crystallization was observed, the filter residue was collected by filtration, and the filter residue was distilled under reduced pressure, and the obtained crystal salt was Accelerator A.

[0064] For the preparation of anaerobic adhesives, add 80 parts by weight of ethoxylated bisphenol A hydroxypropyl methacrylate and 20 parts by weight of epoxy methacrylate to the mixer, and adjust the speed to 550r / min, stir until completely dissolved;

[0065] Then add 0.09 parts by weight of oxalic acid into the mixer, and stir for 30-40min;

[0066] Add 2.4 parts by weight of accelerator A, 0.8 parts by weight of trichloroacetic acid, 3.0 parts by weight of ammonium persulfate, and 0.1 part by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com