A thermal insulation felt with phase change function and preparation method thereof

A phase change and thermal insulation technology, applied in chemical instruments and methods, materials for heat exchange, fiber processing, etc., can solve the problems affecting the performance and safety performance of new energy vehicles, short thermal insulation time, and decreased thermal insulation performance. Achieve the effect of easy automated production, improved performance and safety performance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

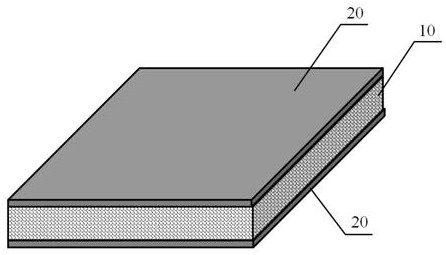

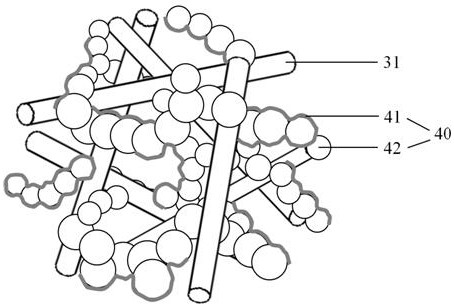

[0056] Thermal insulation felt with phase change function such as figure 1 As shown, it includes an airgel felt 10 and a phase change coating 20 coated on the upper surface and / or lower surface; the airgel felt 10 is mainly composed of a fiber felt 31, and is fully wrapped or half wrapped by a polymer 41 The airgel particles 40 are inserted into the pores of the fiber mat 31; the polymer 41 contains a photosensitive substance.

[0057] The fiber mat is specifically one or more of glass wool, high silica glass fiber, chopped glass fiber, pre-oxidized silk fiber, asbestos fiber and ceramic fiber mixed in any proportion; the bulk density is 10~180kg / m 3 ;

[0058] The airgel particle is a nano particle containing a Si-O-Si network structure, and its primary particle diameter is 1-20nm.

[0059] The thickness of the phase change coating is 0.1-3mm.

[0060] image 3 It is an airgel felt photo, Figure 4 It is a photo of the thermal insulation blanket with phase change functio...

Embodiment 2

[0062] The preparation steps of the thermal insulation felt with phase change function are as follows:

[0063] (1) Sol:

[0064] a. Mix tetraethoxysilane, water and absolute ethanol at a molar ratio of 1:5:50, then add hydrochloric acid / absolute ethanol mixture, stir for 4 hours, adjust the pH of the solution to 3.5, and make it fully hydrolyzed, Prepare sol liquid;

[0065] b. Mix GP-5102 water-soluble polyurethane acrylate (purchased from Shenzhen Youyang Technology Co., Ltd.) and the sol liquid prepared in the above step (1) a according to the mass ratio of 6:100, and then add 1173 photoinitiator, Stir for 2 hours; the mass ratio of 1173 photoinitiator to GP-5102 water-soluble polyurethane acrylate is 1:10;

[0066] c. Add NaOH / absolute ethanol mixed solution to adjust the pH to 7.5 to form a photosensitive sol liquid;

[0067] (2) Preparation of gel felt: Unroll the high-silica needle-punched felt to ensure that each part of the high-silica needle-punched felt is immer...

Embodiment 3

[0089] The preparation steps of the thermal insulation felt with phase change function are as follows:

[0090] (1) Sol:

[0091]a. Mix dimethylethoxysilane, water and absolute ethanol according to the molar ratio of 1:6:80, then add oxalic acid / absolute ethanol mixture, stir for 1.5h, adjust the pH of the solution to 4.0, so that Fully hydrolyzed to obtain a sol liquid;

[0092] b. Mix GP-5120 water-soluble polyurethane acrylate (purchased from Shenzhen Youyang Technology Co., Ltd.) and the sol liquid prepared in the above step (1) a according to the mass ratio of 8:100, and then add 1173 photoinitiator, Stir for 2 hours; the mass ratio of 1173 photoinitiator to GP-5120 water-soluble polyurethane acrylate is 1:15;

[0093] c. Add KOH / dehydrated ethanol mixed solution to adjust the pH to 8.0 to form a photosensitive sol liquid;

[0094] (2) Preparation of gel mat: Unroll the pre-oxidized silk fiber mat to ensure that each part of the pre-oxidized silk fiber mat is immersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com