Process and system for processing waste refractory material of aluminum electrolysis cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

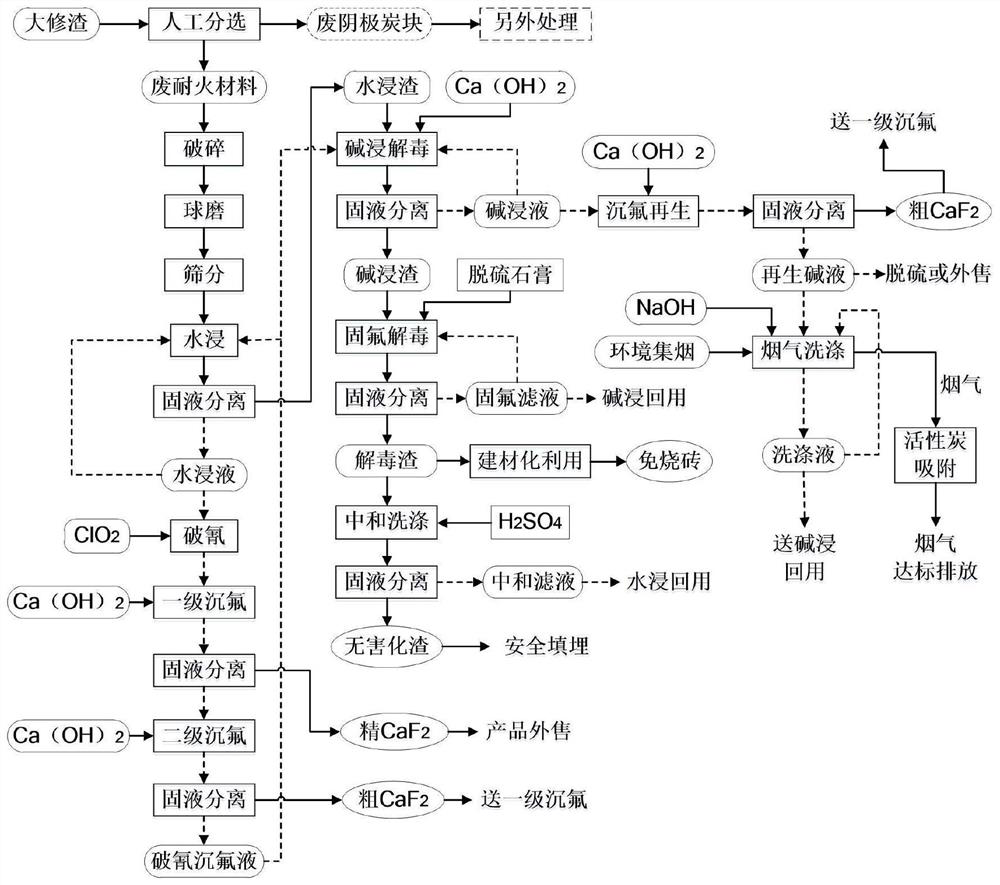

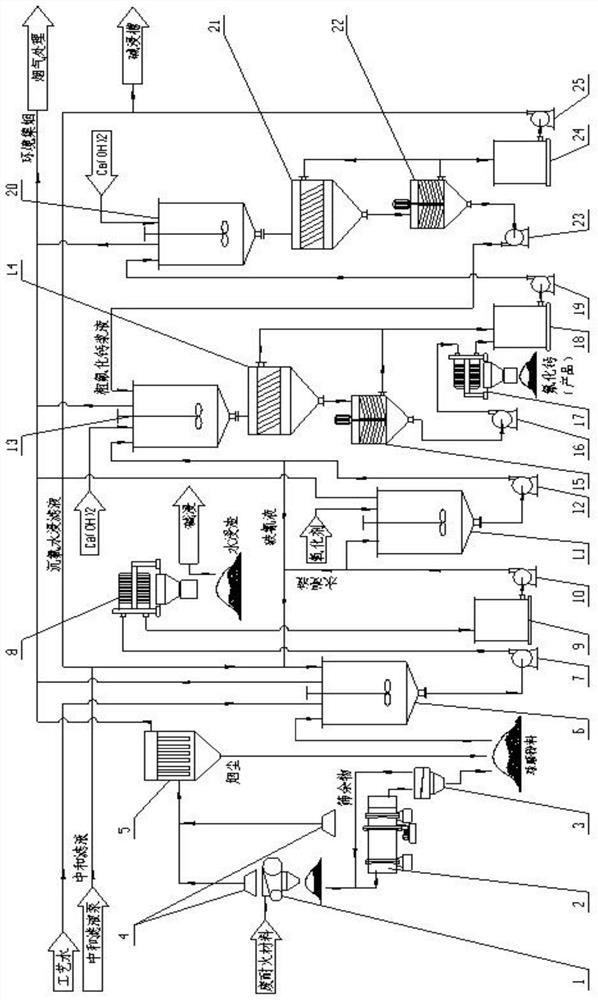

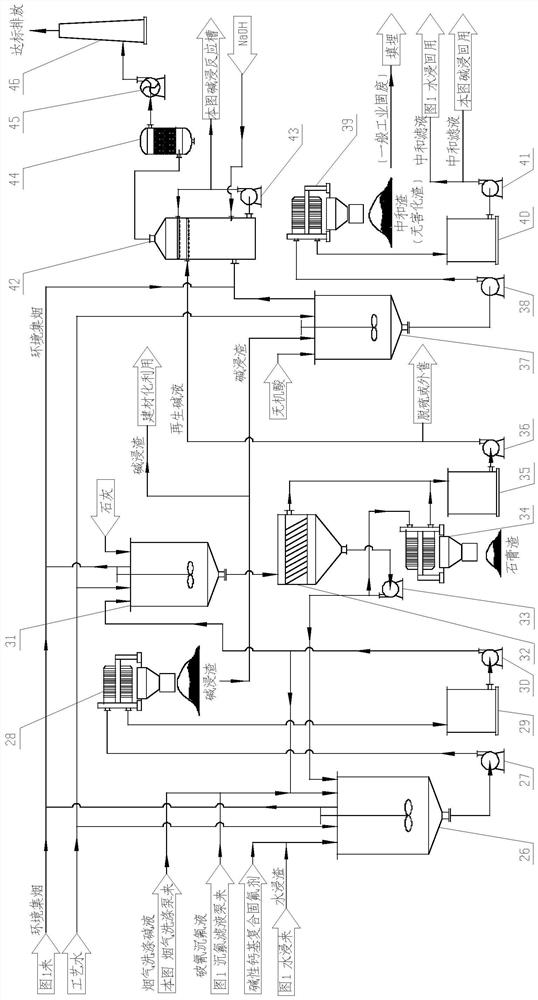

[0037] A waste refractory treatment system for an aluminum electrolytic cell, the system includes a crushing and grinding module, a smoke collection module, a water immersion filter module, a primary fluoride precipitation module, a secondary fluorine precipitation module, an alkali leaching filter module, a neutralization filter module and a smoke filter module. The gas treatment module, the crushing and grinding module, the water immersion filtration module, the primary fluorine precipitation module, the secondary fluorine precipitation module, the alkali leaching filtration module, and the neutralization filtration module are connected in sequence, and the The crushing and grinding module, the smoke collection module, the water immersion filter module, the primary fluoride precipitation module, the secondary fluoride precipitation module, the alkali leaching filter module, and the neutralization filter module are all related to the The flue gas treatment module is connected....

Embodiment 2

[0069] A treatment system for waste refractories in an aluminum electrolytic cell, the system adopts the treatment system described in Example 1.

[0070] The treatment steps of waste refractory materials in aluminum electrolytic cells are as follows:

[0071] A. Crushing, ball milling, and screening: Crusher 1 is used to crush the waste refractory materials to a particle size of <20mm, and the waste refractory materials are sent to the ball mill 2. The ball milling time is 2 hours. The material with a high content of waste cathode carbon blocks should extend the ball milling time appropriately. The final powder is sent to the vibrating sieve 3, sieved with a 3mm sieve, and the under-sieve that passes the sampling inspection is sent to the water immersion reaction tank 6; the screen residue and the unqualified powder are returned to the ball mill 2 to continue ball milling; the waste refractory material is crushed , milling, and sieving to obtain 200-mesh powder;

[0072] B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com