Black molybdenum trioxide nanosheet, preparation method and application thereof

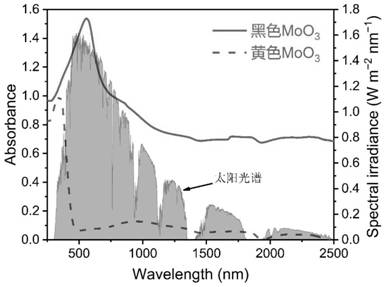

A technology of molybdenum trioxide and nanosheets, applied in chemical instruments and methods, molybdenum oxide/molybdenum hydroxide, general water supply saving, etc., can solve the problems of limitation, low absorption rate of visible light and infrared light, etc., and achieve enhanced absorbance, preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing black molybdenum trioxide nanosheets, comprising:

[0031] A) Mix Mo powder and hydrogen peroxide solution and react to obtain MoO 3 Precursor material liquid;

[0032] B) MoO 3 The precursor material liquid is heated and reacted to obtain a precipitate, which is washed, dried, and calcined to obtain yellow MoO 3 Nanosheets;

[0033] C) Yellow MoO 3 The nanosheets are mixed with the metal powder, dispersed in the solution, mixed with concentrated hydrochloric acid, stirred, washed, and dried to obtain black molybdenum trioxide nanosheets.

[0034] The invention provides a method for preparing black molybdenum trioxide nanosheets, first preparing MoO 3 Precursor material liquid.

[0035] Mix Mo powder and hydrogen peroxide solution and react to obtain MoO 3Precursor material liquid.

[0036] The metal Mo powder was added into the hydrogen peroxide solution, and after heating and magnetic stirring, a soluble precursor ...

Embodiment 1

[0070] Weigh 0.1 g of metal Mo powder, dissolve it in a glass beaker with a volume of 20 mL and a concentration of 1 mol / L hydrogen peroxide ethanol solution, then heat the solution to 70 ° C, and stir for 2 hours to obtain a yellow clear solution

[0071] The above solution was transferred to a 25mL hydrothermal kettle, sealed and heated to 160°C for 18 hours. After the reaction is over, collect the precipitate at the bottom of the kettle, wash it with deionized water and ethanol for 3 times and dry it, put it into a corundum crucible, put it in a muffle furnace, raise the temperature to 600°C, and calcinate in air for 24 hours to obtain Yellow crystalline MoO 3 Nanosheets.

[0072] Take 0.1 g of the above-mentioned yellow crystalline MoO3 powder, mix it with 0.1 g of metal zinc powder, grind it evenly, disperse it in 20 mL of aqueous solution, add 5 mL of concentrated hydrochloric acid solution dropwise under stirring, and continue stirring for 6 hours to obtain black MoO3 ...

Embodiment 2

[0075] Weigh 0.2 grams of metal Mo powder, dissolve it in a glass beaker with a volume of 40 mL and a concentration of 1.5 mol / L hydrogen peroxide ethanol solution, then heat the solution to 60 °C, and stir for 3 hours to obtain a yellow clear solution

[0076] The above solution was transferred to a hydrothermal kettle with a volume of 50 mL, sealed and heated to 170°C for 20 hours. After the reaction is over, collect the precipitate at the bottom of the kettle, wash it with deionized water and ethanol for 3 times and dry it, put it into a corundum crucible, place it in a muffle furnace, raise the temperature to 550°C, and calcinate in air for 22 hours to obtain Yellow crystalline MoO 3 Nanosheets.

[0077] Take the above yellow crystalline MoO 3 Mix 0.2 grams of powder with 0.2 grams of metal copper powder, grind evenly, disperse in 40 mL of aqueous solution, add 10 mL of concentrated hydrochloric acid solution drop by drop under stirring, and continue stirring for 9 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com