Protective coating capable of resisting medium-high temperature steam corrosion as well as preparation method and application thereof

A protective coating, medium and high temperature technology, applied in coatings, metal material coating processes, vacuum evaporation coating and other directions, can solve threats to the safe operation of industrial boilers, waste incinerators in power generation facilities, loss of power factor of nuclear power plants, and reduce nuclear power plants. Operation efficiency and other issues, to achieve the effect of long life and medium and high temperature water vapor protection performance, excellent resistance to medium and high temperature water vapor corrosion performance, and reliable medium and high temperature water vapor protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

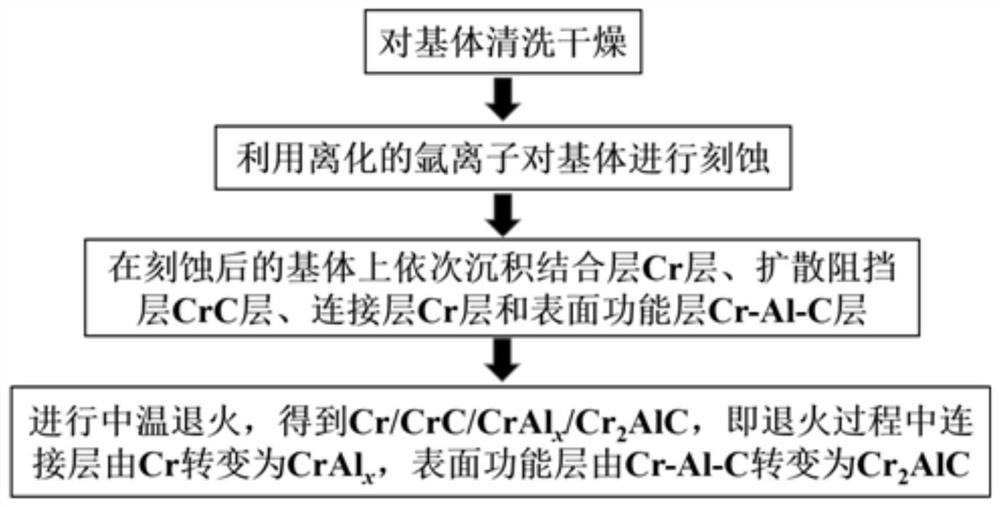

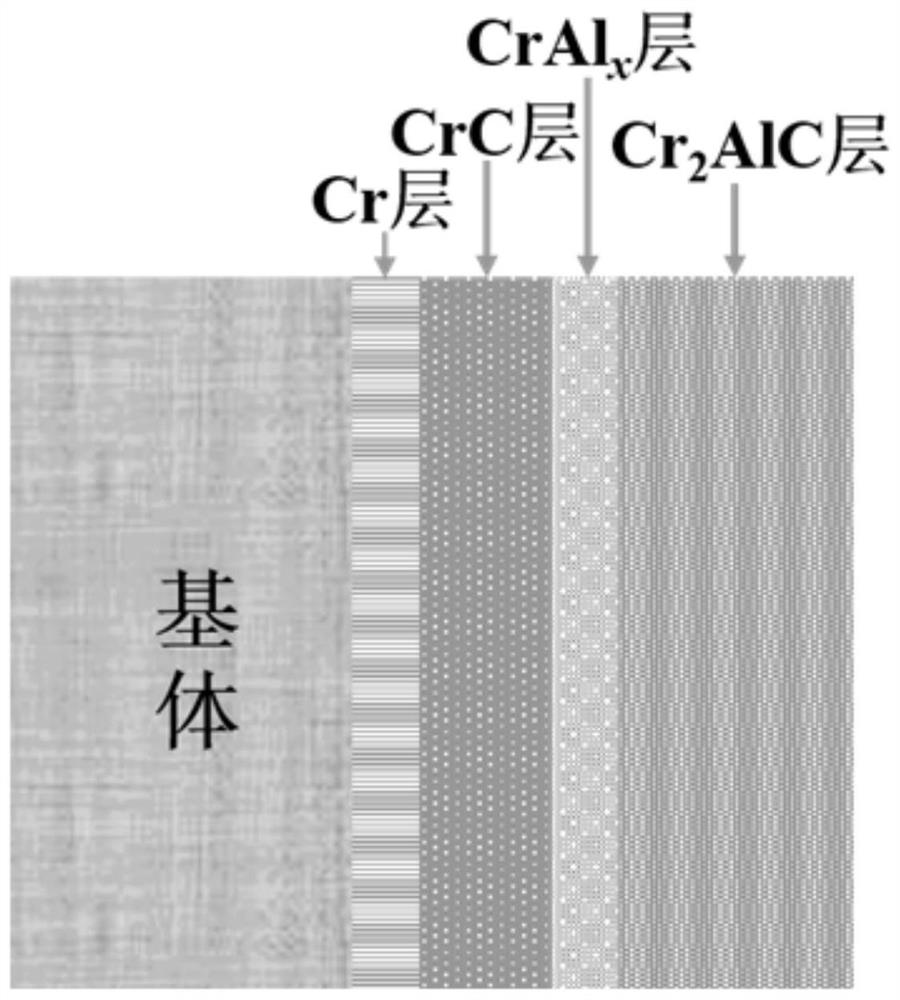

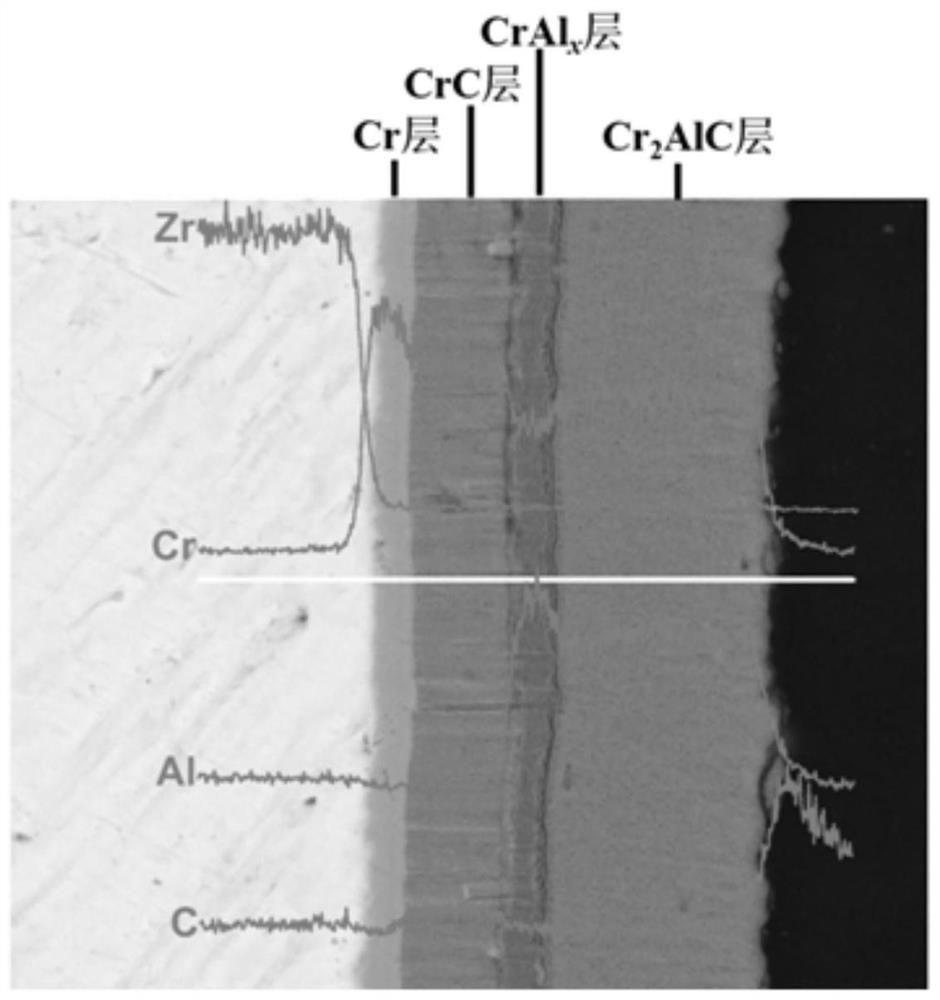

[0037] As another aspect of the technical solution of the present invention, it relates to the preparation method of the aforementioned protective coating resistant to medium and high temperature water vapor corrosion, which includes: adopting arc ion plating technology to sequentially deposit a Cr layer, a CrC layer, Cr layer and Cr-Al-C film layer to form Cr / CrC / Cr / Cr-Al-C multilayer film coating, followed by medium and low temperature annealing treatment to obtain Cr / CrC / CrAl x / Cr 2 AlC coating, that is, to obtain the protective coating against medium and high temperature water vapor corrosion.

[0038] In some embodiments, the preparation method further includes: before depositing the Cr layer on the surface of the substrate, etching the substrate with ionized argon ions.

[0039] Further, the process conditions adopted in the etching treatment include: the chamber pressure is 0.2-0.6Pa, the Ar flow rate is 20sccm-60sccm, the anode ion source current is 0.1-0.3A, and the...

Embodiment 1

[0081] Put the Zr alloy matrix after cleaning and drying into the vacuum chamber, first pass into the vacuum chamber 40sccm of argon gas, set the current of the linear anode ion source to 0.2A, and the chamber pressure to 0.4Pa. The substrate was etched by ions for 30 minutes; then the Cr bonding layer was deposited by arc ion plating technology, the target was Cr target, the substrate negative bias was -150V, the arc current was 70A, the Ar gas pressure was 1.0Pa, and the deposition thickness was 1.5μm ; Then pass the reaction gas CH 4 , CH 4 The air pressure is 1.5Pa, the arc current is 70A, the bias voltage is -100V, and the CrC diffusion barrier layer is deposited with a thickness of 4.5μm; the third step is to introduce Ar gas, the Ar gas pressure is 1.0Pa, the arc current is 70A, and the bias voltage is -100V, the deposition thickness is 2.0μm; the fourth step uses arc ion plating technology to deposit Cr-Al-C coating, the target is CrAl composite target, the current is...

Embodiment 2

[0084] Put the cleaned and dried Zr alloy substrate into the vacuum chamber, firstly feed 20 sccm of argon gas into the vacuum chamber, set the current of the linear anode ion source to 0.1A, and the chamber pressure to 0.6Pa. The substrate was etched by ions for 40 minutes; then the Cr bonding layer was deposited by arc ion plating technology, the target was Cr target, the negative bias of the substrate was -100V, the arc current was 60A, the Ar gas pressure was 1.5Pa, and the deposition thickness was 0.5μm ; Then pass the reaction gas CH 4 , CH 4 The pressure is 1Pa, the arc current is 60A, the bias voltage is -150V, and the CrC diffusion barrier layer is deposited with a thickness of 1μm; the third step is to introduce Ar gas, the Ar gas pressure is 1.5Pa, the arc current is 60A, and the bias voltage is - 150V, the deposition thickness is 2.5μm; the fourth step uses arc ion plating technology to deposit Cr-Al-C coating, the target is CrAl composite target, the current is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com