Method for depositing polycrystalline diamond clad sheet of CVD diamond coating at low temperature

A technology of polycrystalline diamond and diamond coating, which is applied in metal material coating technology, coating, metal processing equipment, etc., and can solve the problems of high drill replacement costs and reduced drill life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

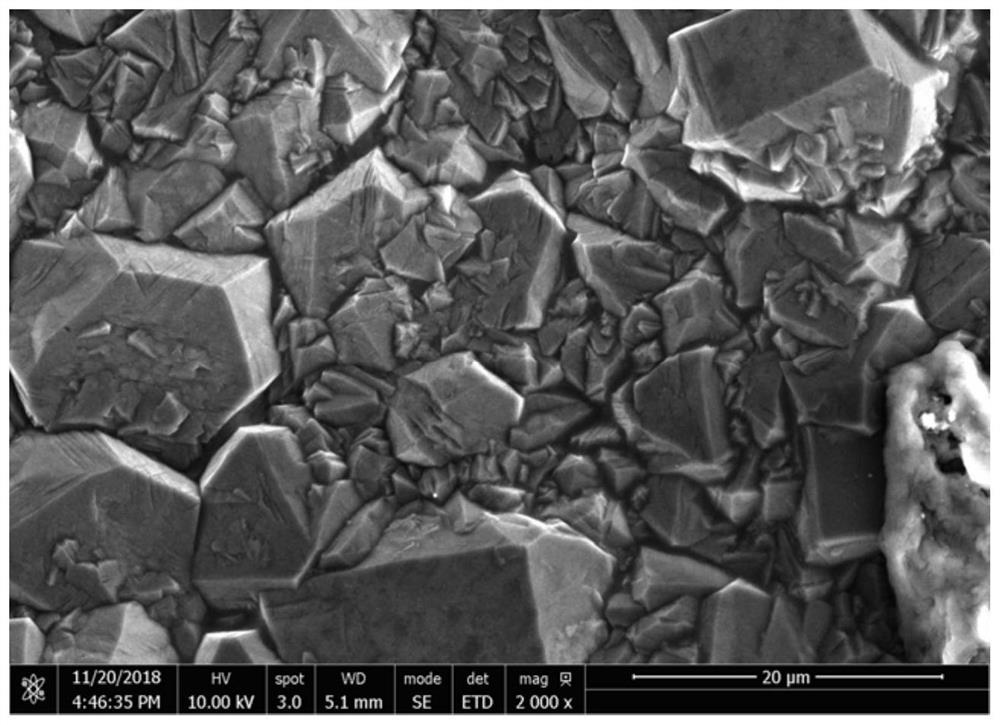

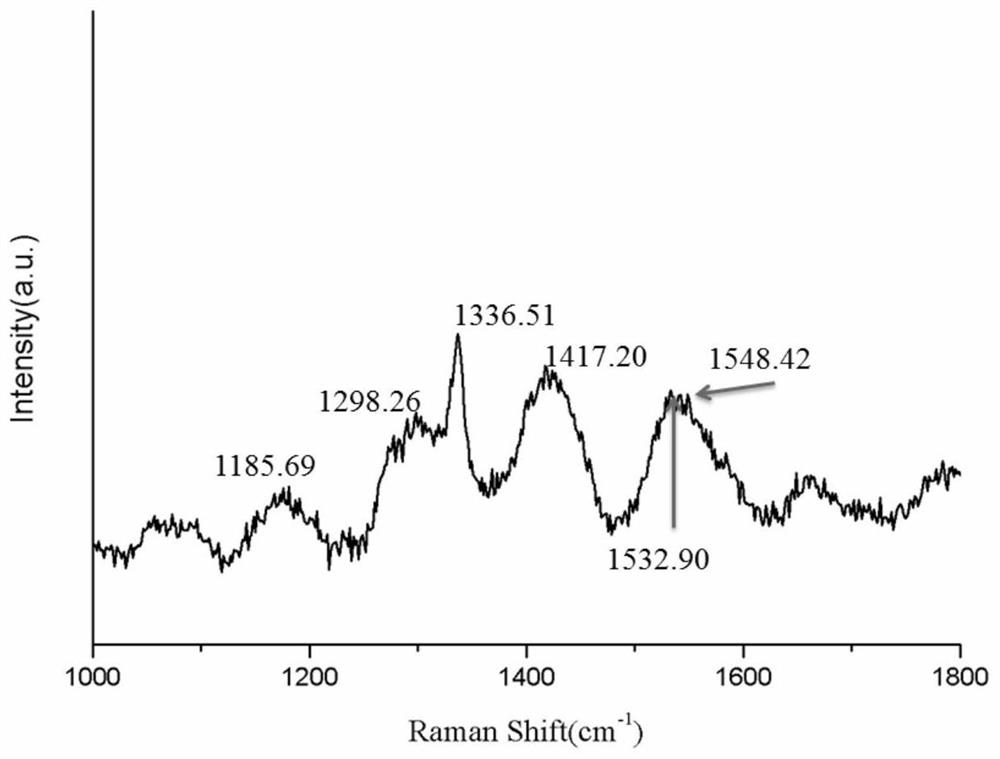

[0047] A method for low-temperature deposition of a CVD diamond coating based on an improved substrate formula polycrystalline diamond compact, comprising the following steps:

[0048] (1) Improved polycrystalline diamond composite substrate formula

[0049] Change the base formula of the polycrystalline diamond composite sheet. According to the mass parts, the ratio of diamond powder to metal alloy is 4:1, wherein, diamond powder: 25 / 30 mesh (that is, 25-30 mesh, the same below) and 40 / 50 mesh ( That is, 40-50 mesh) mixed, and 25 / 30:40 / 50=1:1 (mass ratio, the same below); the metal alloy contains 50wt% of WC, 7wt% of Co, and 28wt% of Cu , containing Sn as 15wt%. The polycrystalline diamond powder and cemented carbide powder are directly placed in the mold, and the powder metallurgy method is used to sinter at 5GPa, 1200°C, the holding time is 15min, the temperature is lowered to 800°C, and the furnace is air-cooled to room temperature.

[0050] (2) CVD diamond coating depos...

Embodiment 2

[0058] A method for low-temperature deposition of a CVD diamond coating based on an improved substrate formula polycrystalline diamond compact, comprising the following steps:

[0059] (1) Improved polycrystalline diamond composite substrate formula

[0060] Change the base formula of the polycrystalline diamond composite sheet. According to the mass parts, the ratio of diamond powder to metal alloy is 4:1, wherein, diamond powder: 25 / 30 mesh (that is, 25-30 mesh, the same below) and 40 / 50 mesh ( That is, 40-50 mesh) mixed, and 25 / 30:40 / 50=1:1 (mass ratio, the same below); the metal alloy contains 54wt% of WC, 6wt% of Co, and 30wt% of Cu , containing Sn as 10wt%. The polycrystalline diamond powder and cemented carbide powder are directly placed in the mold, and the powder metallurgy method is used to sinter at 5GPa, 1100°C, the holding time is 10min, the temperature is lowered to 800°C, and the furnace is air-cooled to room temperature.

[0061] (2) CVD diamond coating depos...

Embodiment 3

[0069] A method for low-temperature deposition of a CVD diamond coating based on an improved substrate formula polycrystalline diamond compact, comprising the following steps:

[0070] (1) Improved polycrystalline diamond composite substrate formula

[0071] Change the base formula of the polycrystalline diamond composite sheet. According to the mass parts, the ratio of diamond powder to metal alloy is 4:1, wherein, diamond powder: 25 / 30 mesh (that is, 25-30 mesh, the same below) and 40 / 50 mesh ( That is, 40-50 mesh) mixed, and 25 / 30:40 / 50=1:1 (mass ratio, the same below); the metal alloy contains 58wt% of WC, 3wt% of Co, and 34wt% of Cu , containing Sn as 5wt%. The polycrystalline diamond powder and cemented carbide powder are directly placed in the mold, and the powder metallurgy method is used to sinter at 5GPa, 1000°C, the holding time is 5min, the temperature is lowered to 800°C, and the furnace is air-cooled to room temperature.

[0072] (2) CVD diamond coating deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com