Carbon-coated nickel carbide nano composite material as well as preparation method and application thereof

A nanocomposite material, nickel carbide technology, applied in chemical instruments and methods, hydrogenation hydrocarbon production, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A second aspect of the present invention provides a method for preparing the above carbon-coated nickel carbide nanocomposite, comprising the following steps:

[0044] The nickel source, carboxylic acid and nitrogen-containing compound are placed in a solvent, heated and stirred to form a homogeneous solution;

[0045] removing the solvent in the homogeneous solution to obtain a precursor;

[0046] And the precursor is pyrolyzed under an inert atmosphere to obtain a nanocomposite material;

[0047] Wherein, the pyrolysis temperature is 350°C to 390°C.

[0048] According to the present invention, in early studies, the inventors found that carbon-coated nickel nanocomposites can be obtained by precursor pyrolysis, for example, patent CN 109309213A discloses a carbon-coated nickel nanocomposite and its preparation method , wherein the temperature of the precursor constant temperature section is 425°C to 800°C. In fact, the temperature range for the preparation of carbon...

Embodiment 1

[0067] This example is used to illustrate the preparation of the carbon-coated nickel carbide nanocomposite material of the present invention.

[0068] Weigh 10.51g (50mmol) of citric acid monohydrate, 4.64g (50mmol) of nickel hydroxide, 6.31g (75mmol) of dicyandiamide into 200mL of deionized water, stir at 105°C to obtain a homogeneous solution, and continue to heat and evaporate to dryness , the precursor is obtained after grinding the solid.

[0069] Take 7.5g of the obtained precursor and place it in a porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, feed nitrogen gas with a flow rate of 100mL / min, and raise the temperature to 390°C at a rate of 2°C / min, and keep the temperature constant for 120min Then stop heating, and cool to room temperature under a nitrogen atmosphere to obtain a nitrogen-doped carbon-coated nickel carbide nanocomposite material.

[0070] Material Characterization:

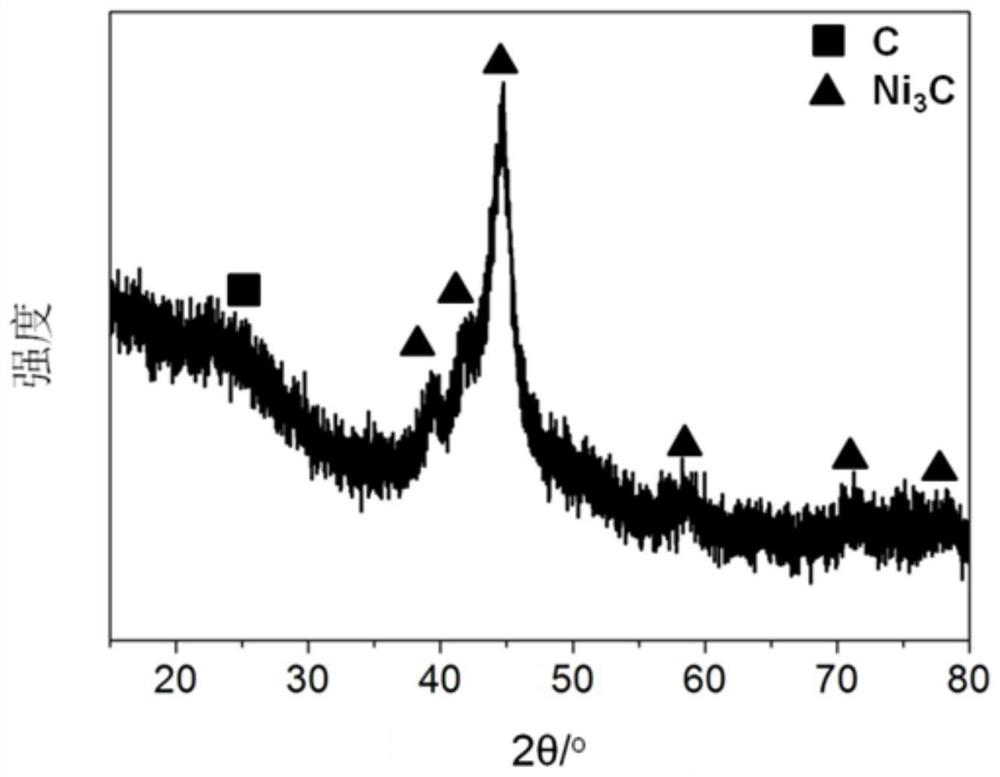

[0071] figure 1 It is the X-ray...

Embodiment 2

[0073] Weigh 14.61g (50mmol) of ethylenediaminetetraacetic acid, 9.27g (100mmol) of nickel hydroxide into 200mL of deionized water, stir at 110°C to obtain a homogeneous solution, then lower the temperature to 90°C and add 4.20g (50mmol) of dihydrogen Cyanamide and continue to heat and evaporate to dryness, and the precursor is obtained after grinding the solid.

[0074] Take 7g of the obtained precursor and place it in a porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, pass nitrogen gas at a flow rate of 100mL / min, and raise the temperature to 370°C at a rate of 2°C / min, and keep the temperature for 120min Stop heating, and cool to room temperature under a nitrogen atmosphere to obtain a nitrogen-doped carbon-coated nickel carbide nanocomposite material.

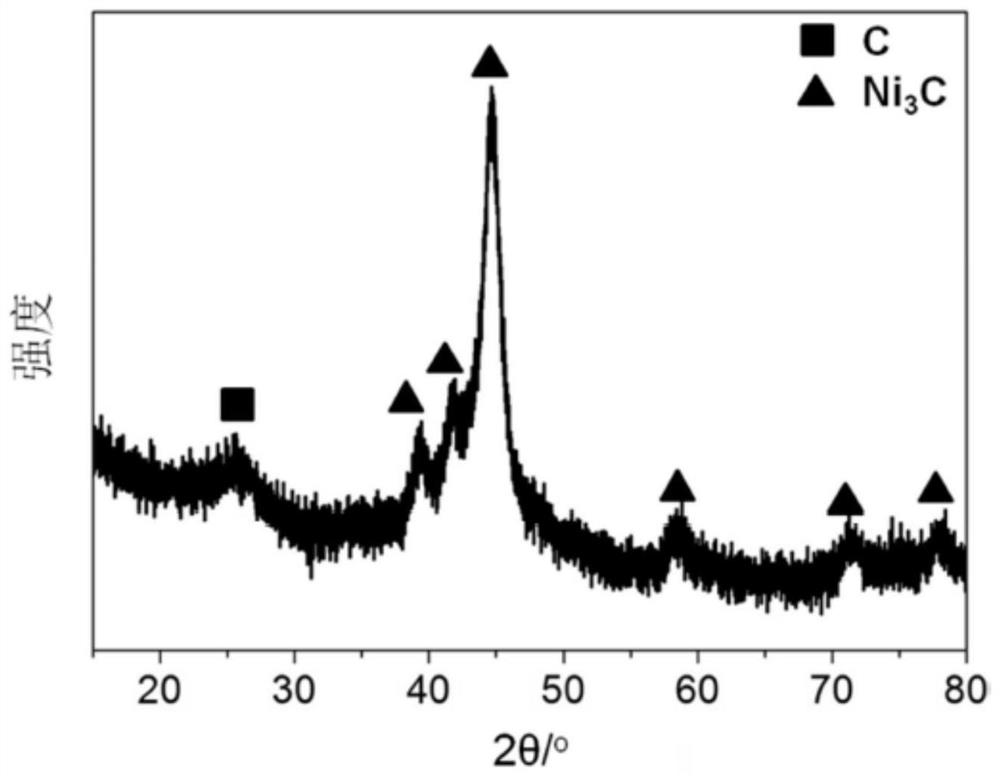

[0075] Transfer the obtained nitrogen-doped carbon-coated nickel carbide nanocomposite to a flask, add 50 mL of deionized water, stir at 60°C for 20 minutes, then filter wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com