Gypsum plaster board and preparation method thereof

A technology of paper surface gypsum board and gypsum clinker, which is applied in the field of gypsum board and its preparation, and can solve the problems of influence, reduction of mechanical properties of gypsum board, poor performance of gypsum products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

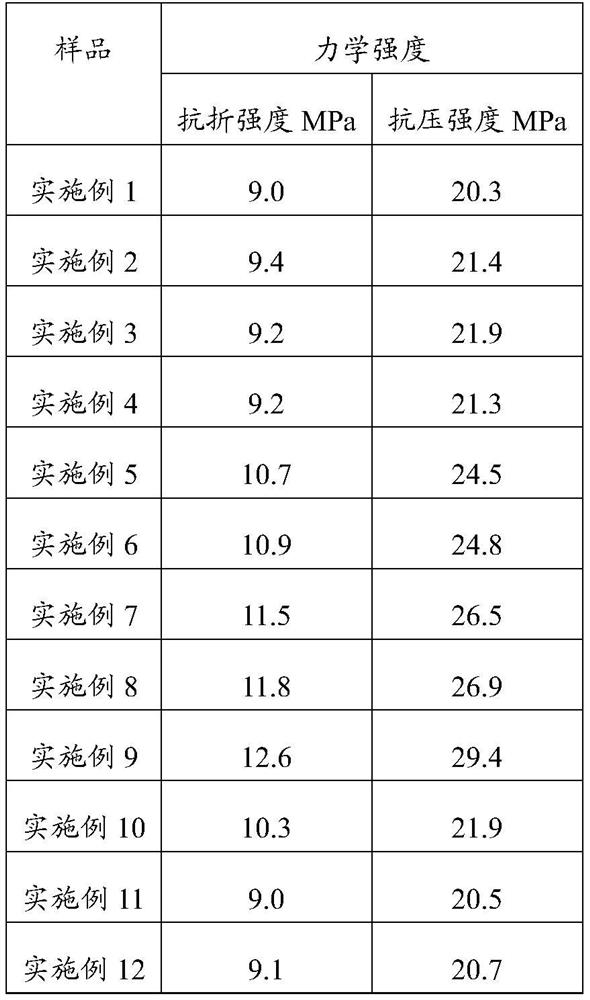

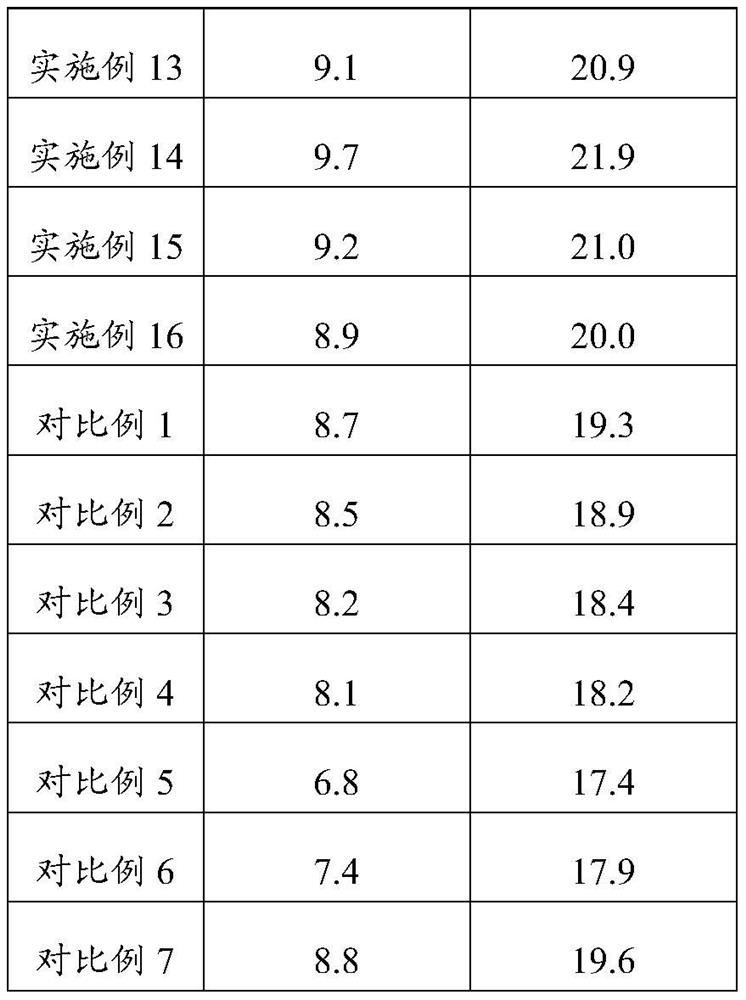

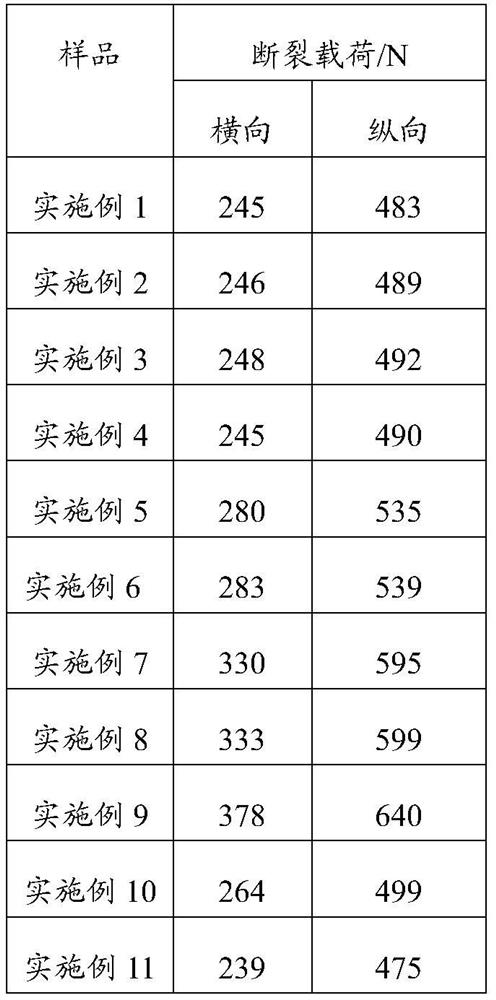

Examples

preparation example Construction

[0052] In yet another aspect, the embodiment of the present application provides a method for preparing the above-mentioned gypsum board, comprising the following steps:

[0053] The raw materials of the board core are mixed evenly to form a gypsum slurry. After the gypsum slurry is formed, it is lapped and bonded with the face paper to form a wet board. The wet board is at 15°C to 30°C and the humidity is 50%. Curing at 70% medium temperature for 1 to 7 days, the wet board curing temperature does not exceed 40°C, and finally the wet board is dried to obtain a gypsum board.

[0054] In the embodiment of the present application, the thickness of the gypsum board substrate is 9.5 mm to 12 mm.

[0055] In the examples and comparative examples of the present application, magnesium oxide was purchased from Hebei Meisheng Chemical Technology Co., Ltd., with a purity of ≥99%, 1000 mesh, d 50 3μm to 5μm, d 90 10μm to 15μm.

[0056] In the examples and comparative examples of the pr...

Embodiment 1

[0080] The gypsum clinker is selected, the magnesium ion content in the gypsum clinker is 0.1wt.%, and the chloride ion content is 200ppmw. Pass 1000 grams of gypsum clinker through an 80-mesh sieve. Choose an appropriate amount of citric acid gypsum (the calcium sulfate dihydrate in the citric acid gypsum is 99wt.%, and the residual citric acid in the citrate gypsum is 0.3wt.%). After drying (45°C), grind to a particle size of 400nm to 800nm, Weigh 10g for later use. Take by weighing magnesia 8g (magnesia and impurity ion Mg 2+ The molar ratio is 4.8:1). Mix magnesium oxide, gypsum clinker, 10g expanded vermiculite nanosheets, 5g polyvinyl alcohol, 5g starch, 5g rubber powder and 0.5g water reducer evenly, and then mix evenly with citrate gypsum. Determine the mixing water content according to the water consumption of the standard consistency, add 0.2g foaming agent to the mixing water and stir evenly. The mixed powder is added to the mixing water to prepare a slurry, and...

Embodiment 2

[0082] The gypsum clinker is selected, the magnesium ion content in the gypsum clinker is 0.15wt.%, and the chloride ion content is 1000ppmw. Pass 1000 grams of gypsum clinker through an 80-mesh sieve. Choose an appropriate amount of citric acid gypsum (the calcium sulfate dihydrate in the citric acid gypsum is 99wt.%, and the residual citric acid in the citrate gypsum is 0.3wt.%). After drying (45°C), grind to a particle size of 400nm to 800nm, Weigh 8g for later use. Take by weighing magnesium oxide 12.5g (magnesium oxide and impurity ion Mg 2+ The molar ratio is 5:1). Mix magnesium oxide, gypsum clinker, 10g expanded vermiculite nanosheets, 5g polyvinyl alcohol, 5g starch, 5g rubber powder and 0.5g water reducer evenly, and then mix evenly with citrate gypsum. Determine the mixing water content according to the water consumption of the standard consistency, add 0.2g foaming agent to the mixing water, and stir evenly. The mixed powder is added to the mixing water to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com