Quick-drying finish paint based on nano-modified alkyd resin and preparation process thereof

A technology of alkyd resin and nano-modification, applied in the field of coatings, which can solve the problems of long drying time, low hardness, and low drying speed of alkyd resin, and achieve the effects of fast surface drying, high hardness, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

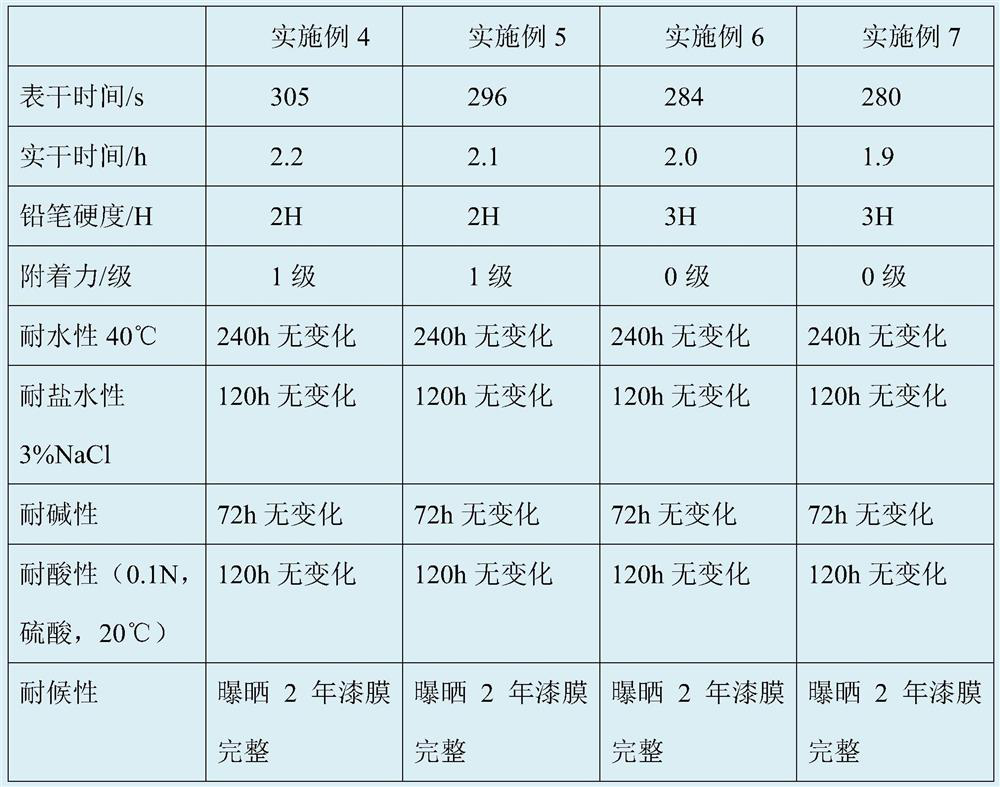

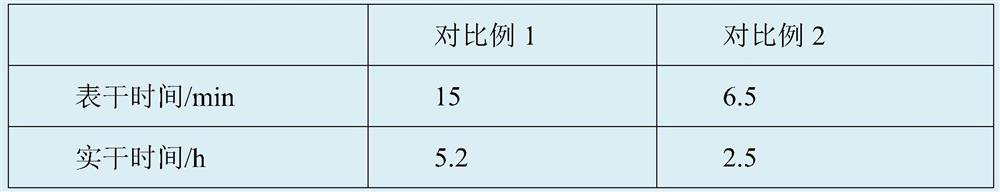

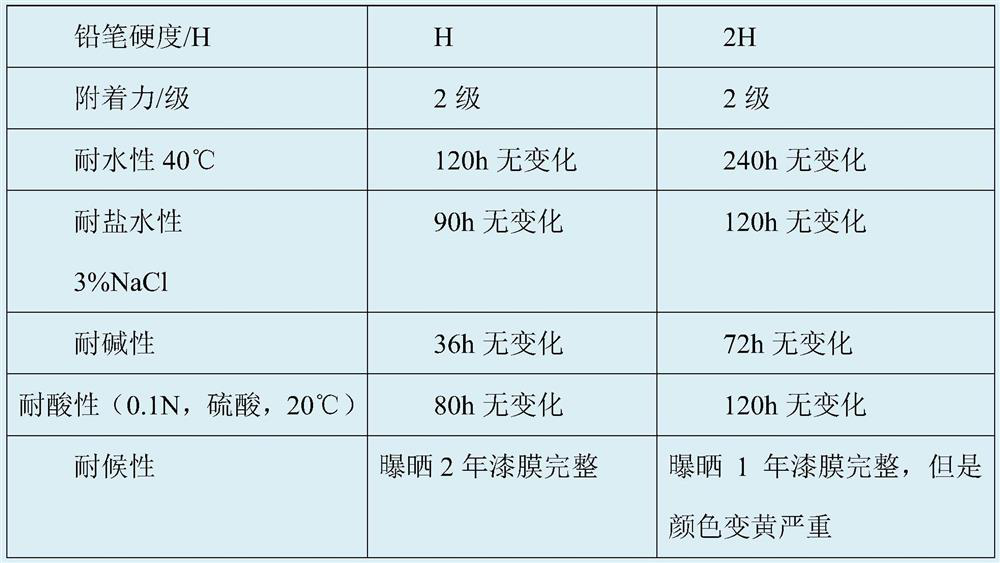

Examples

preparation example Construction

[0074] The present invention also includes a kind of preparation method based on the quick-drying finish paint of nano-modified alkyd resin, comprises the following steps:

[0075] In parts by weight, 5-10 parts of itaconic acid modified styrene-acrylic resin, 50-60 parts of alkyd resin, 0.1-0.5 parts of defoamer, 30-40 parts of solvent, 0.5-1 part of film-forming aid and Mix and stir 0.2-0.5 parts of dispersant, grind until the fineness is less than 50 μm, add 4-8 parts of nano-silica modified hollow glass microspheres, and stir for 20-30 minutes to mix evenly to obtain a nano-modified alkyd resin-based dry finish;

[0076] The itaconic acid modified styrene-acrylic resin is prepared according to the following steps:

[0077] ① In parts by weight, dissolve and disperse 1 to 3 parts of polyoxyethylene polyoxypropylene ether, 1 to 3 parts of Tween, and 0.1 to 0.5 parts of disodium hydrogen phosphate into 20 to 30 parts of xylene to obtain an emulsifier buffer , refrigerated f...

Embodiment 1

[0090] A kind of alkyd resin is prepared according to the following steps:

[0091] Add 40kg of unsaturated fatty acid, 30kg of polyol, 10kg of phthalic anhydride, 0.02kg of hydroquinone (inhibitor) and 20kg of xylene into the reactor, slowly heat up to 150°C, and keep warm until the acid value is less than 10mg KOH / g, stop the reaction, lower the temperature, and add 25kg of cosolvent to obtain alkyd resin;

[0092] The unsaturated fatty acid is rapeseed acid;

[0093] The polyhydric alcohol is glycerol;

[0094] The co-solvent is dipropylene glycol dimethyl ether.

Embodiment 2

[0096] A kind of alkyd resin is prepared according to the following steps:

[0097] Add 25kg of ricinoleic acid, 25kg of rapeseed oleic acid, 20kg of polyols, 15kg of phthalic anhydride, 0.05kg of hydroquinone (inhibitor) and 30kg of xylene into the reactor, and slowly heat up to 160°C. Insulate the reaction until the acid value is less than 10mgKOH / g, stop the reaction, lower the temperature, and add 35kg of co-solvent to obtain the alkyd resin;

[0098] Described polyhydric alcohol is pentaerythritol;

[0099] The co-solvent is propylene glycol methyl ether acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com