Downstream centrifugal flue gas waste heat recovery device

A flue gas waste heat and recovery device technology, applied in gas treatment, separation methods, adsorption machines, etc., can solve problems such as increased flue gas circulation resistance, low heat, and increased load transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

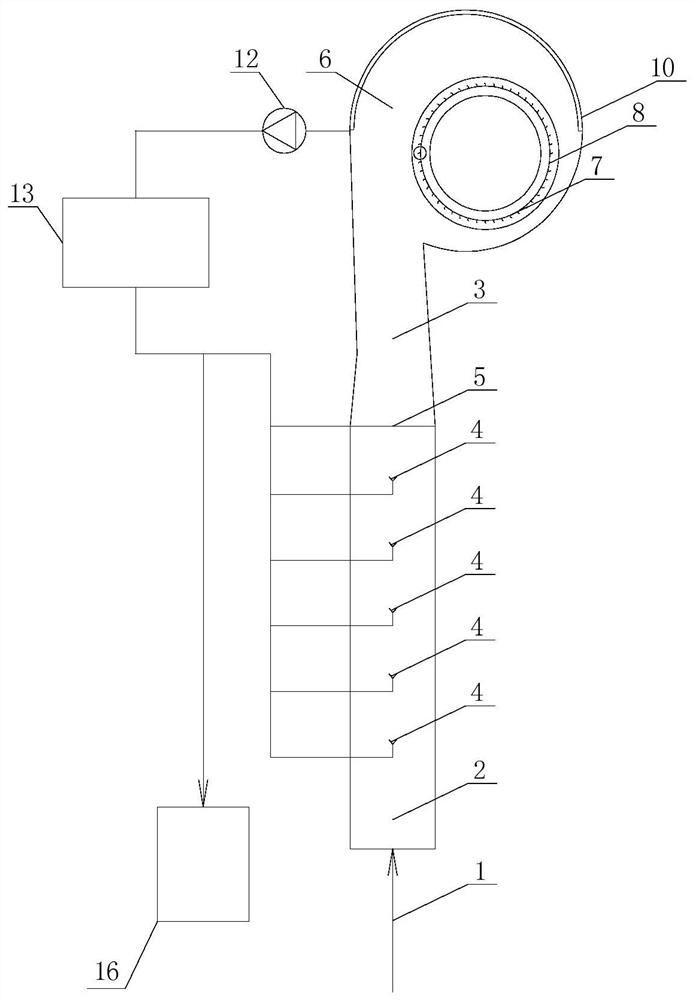

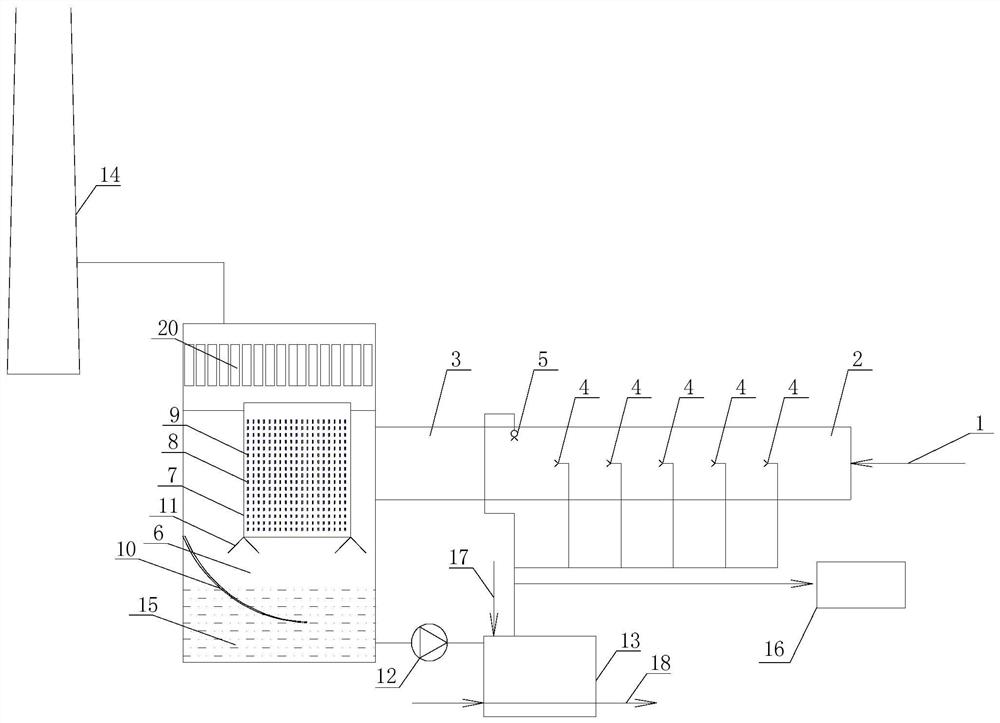

[0023] Such as figure 1 As shown, a downstream centrifugal flue gas waste heat recovery device, the horizontal flue 2 has a shrinkage acceleration mixing section 3, the shrinkage acceleration mixing section 3 is connected to a swirl tower 6, and a drainage plate 10 is installed on the wall of the swirl tower 6, The inner chamber of the swirl tower 6 is equipped with an eccentric stainless steel central cylinder 7, the upper part of the eccentric stainless steel central cylinder 7 is connected to the tube bundle demister 20, the tube bundle demister 20 is connected to the chimney 14 through the flue, and the bottom of the lower pool 15 of the swirl tower 6 passes through The pipeline is connected to the cooling water circulation pump 12, and the other end of the cooling water circulation pump 12 is connected to the lithium bromide absorption heat pump unit 13 through the pipeline, and the output pipeline of the lithium bromide absorption heat pump unit 13 is respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com