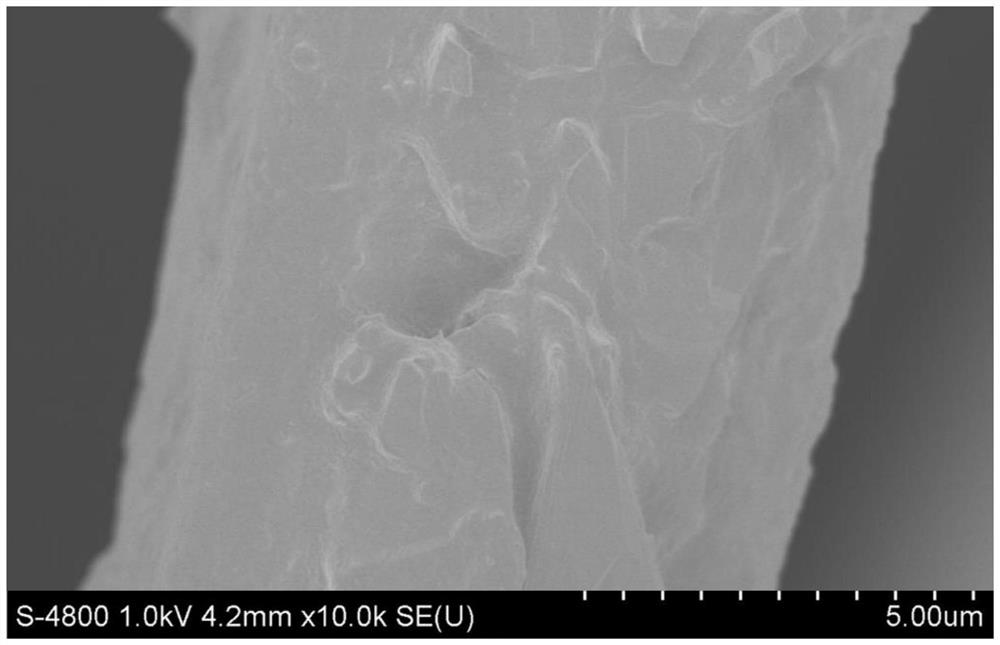

Graphene nanosheet porous photo-thermal conversion material as well as preparation method and application thereof

A graphene nanosheet, photothermal conversion technology, applied in chemical instruments and methods, separation methods, heating water/sewage treatment, etc., can solve problems such as hindering practical application, difficulty in dispersion, high cost, etc. Evaporation efficiency, good recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] a. Add 0.5g of graphite particles (325 mesh size) into 50g of methyl acrylate, and disperse by ultrasonic, the ultrasonic power is 300W, the ultrasonic time is 30min, and then 0.05g of azobisisobutylene is added Nitrile (initiator) and 0.1 g of divinylbenzene (DVB, cross-linking agent), stir well;

[0044] b. Immerse the melamine sponge in water after hot pressing, squeeze out excess water after taking out, and immerse in the solution obtained in the above a. The volume ratio of the immersion liquid and the melamine sponge is 3:1, and the time of the immersion treatment is 5min. The modified solution absorbed in the melamine sponge was extruded by manual extrusion until no liquid dripping was observed with the naked eye within 30s, the extrusion treatment was completed, and the process was repeated 3 times;

[0045] c. Put the sponge into the oven, raise it to 80°C for heating, curing and polymerization for 2h;

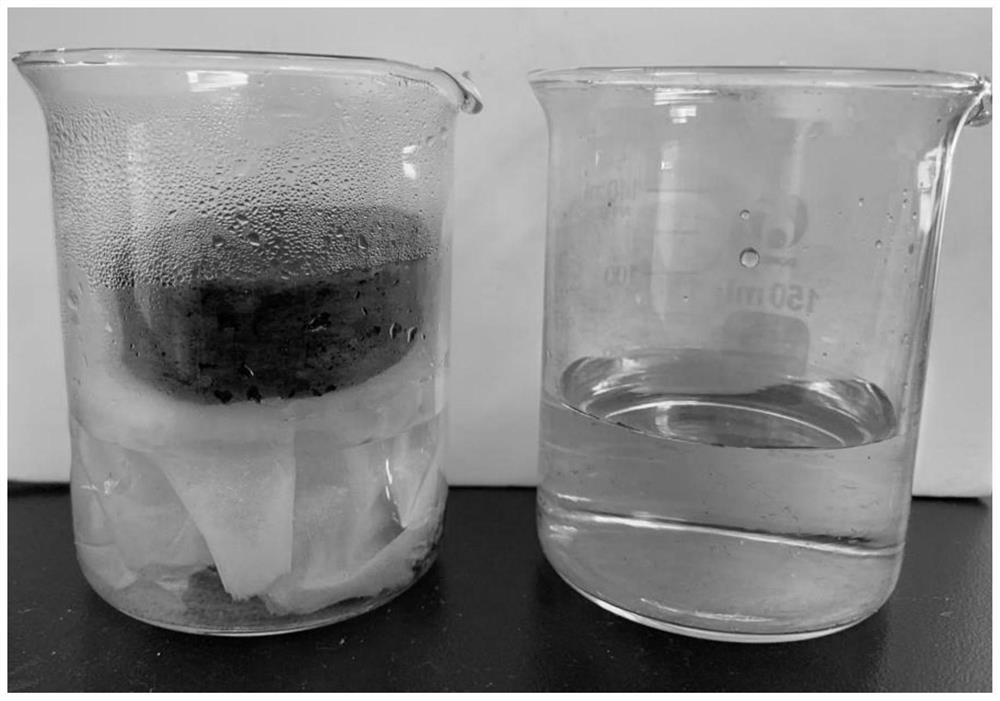

[0046] Photothermal conversion performance test: The obt...

Embodiment 2

[0050] a. Add 0.85 g of graphite particles (with a particle size of 325 mesh) into 50 g of methyl acrylate, and disperse them by ultrasonic. The ultrasonic power is 300 W, and the ultrasonic time is 30 min. Then add the azobisisobutyronitrile (initiator) of 0.05g and the divinylbenzene (DVB, crosslinking agent) of 0.1g, stir;

[0051] b. Hot-press the melamine sponge and immerse it in water, squeeze out the excess water after taking it out, and immerse it in the solution obtained in the above a. The volume ratio of the immersion liquid to the melamine sponge is 3:1, and the time for immersion treatment is 5 minutes. Squeeze out the modified solution absorbed in the melamine sponge by manual extrusion until the liquid dripping is not observed with the naked eye within 30s, and the extrusion process is completed, and the process is repeated 3 times;

[0052] c. Put the sponge into the oven, raise it to 80°C for heating, curing and polymerization for 2 hours;

[0053] Light-to-h...

Embodiment 3

[0055] a. Add 0.85g of graphite particles (325 mesh particle size) into the mixed monomer of 5g lauryl acrylate and 50g styrene, and disperse by ultrasonic, the ultrasonic power is 300W, the ultrasonic time is 90min, and then add 0.2g of lauroyl peroxide (initiator) and 0.17g of tetraethyloxysilane (TEOS, cross-linking agent) are stirred evenly;

[0056] b. Immerse the polyvinyl alcohol sponge in water, squeeze out the excess water after taking it out, and immerse it in the solution obtained in the above a. The volume ratio of the immersion liquid to the sponge is 3:1, and the immersion treatment time is 5 minutes. Squeeze out the modified solution absorbed in the sponge by manual extrusion until no dripping of the liquid is observed with the naked eye within 30s, complete the extrusion process, and repeat the process 3 times;

[0057] c. Place the sponge under a UV lamp for photocuring and polymerization for 1 hour;

[0058] Light-to-heat conversion performance test: place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com