Three-dimensional porous material containing lithium alloy skeleton network and preparation method thereof, and composite lithium negative electrode material and a preparation method thereof

A three-dimensional porous, skeleton network technology, applied in negative electrodes, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problem of induced lithium nucleation, limited growth effect, large size and thickness of metallic lithium, easy to appear Lithium dendrites, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preferred embodiment of the present invention provides a method for preparing nickel foam containing a lithium-zinc alloy skeleton network and its composite lithium negative electrode material. The specific steps are as follows:

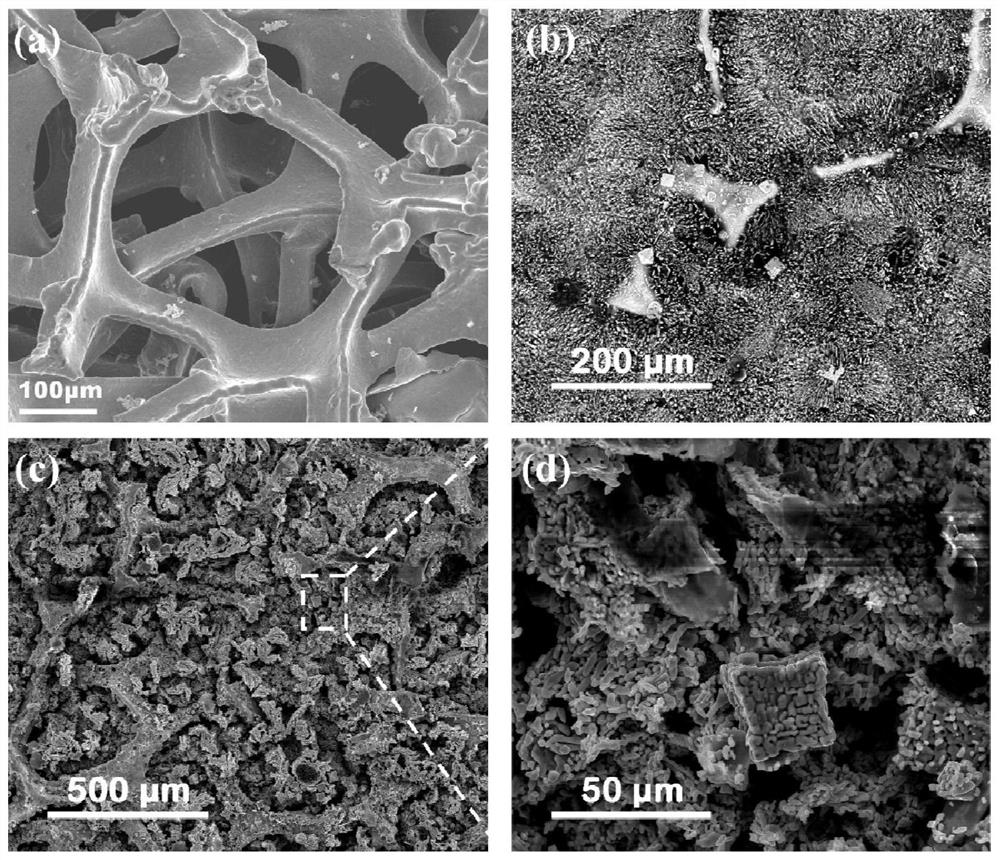

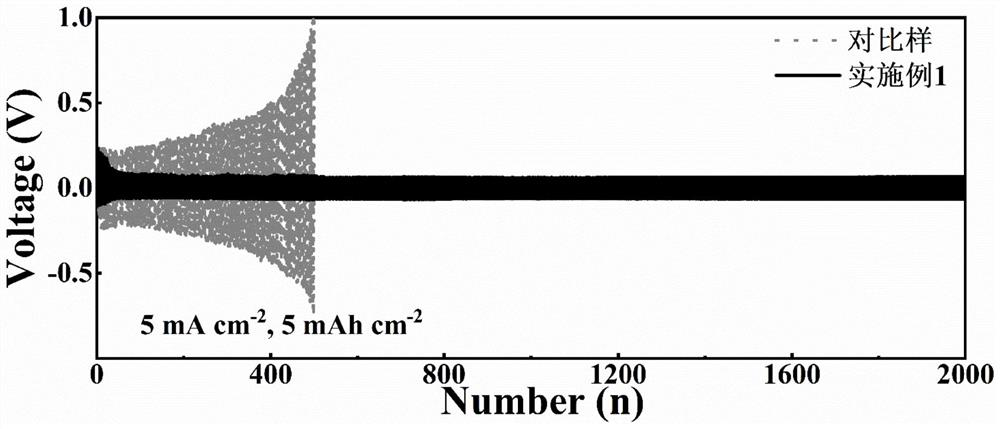

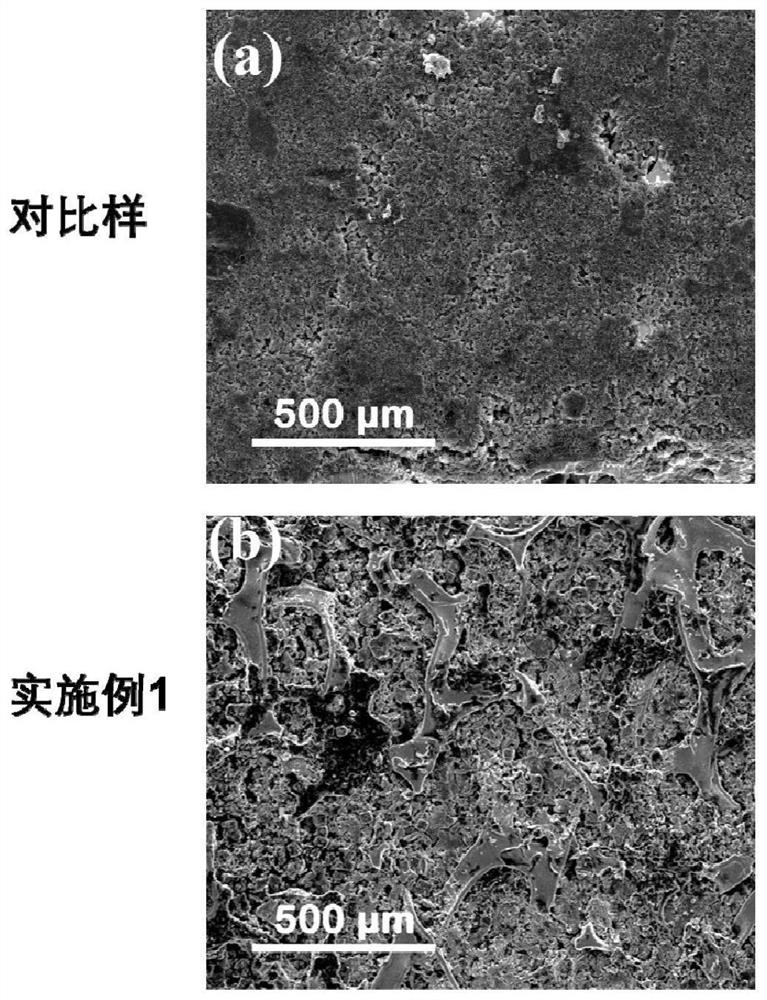

[0041] Metal zinc and metal lithium are placed in a crucible with a molar ratio of 1:10, and the temperature is raised to 400°C under an argon atmosphere to make the metal mixture into a molten state, and a molten lithium-rich lithium-zinc alloy is obtained. Raw nickel foam such as figure 1 as shown in a. Then place the nickel foam on the molten lithium-rich lithium-zinc alloy, and pour the molten alloy into the structure of the nickel foam, and the filling thickness accounts for 4 / 4 of the thickness of the entire substrate. Finally, it is cooled to room temperature within 600s to obtain a composite lithium negative electrode material containing a lithium-zinc alloy skeleton network and foamed nickel, such as figure 1 As shown in b, after ...

Embodiment 2

[0043] A preferred embodiment of the present invention provides a method for preparing a foamed copper three-dimensional porous material containing a lithium alloy skeleton network and a composite lithium negative electrode material thereof. The specific steps are as follows:

[0044] Metal copper and metal lithium are placed in a crucible with a molar ratio of 1:60, and the temperature is raised to 500°C under an argon atmosphere to make the metal mixture into a molten state, and a molten lithium-rich lithium-copper alloy is obtained. Then, the foamed copper is placed on the molten lithium-rich lithium copper alloy, and the molten alloy is hot poured into the structure of the foamed copper, and the filling thickness accounts for 1 / 4 of the thickness of the entire substrate. Finally, it was cooled to room temperature within 200s to obtain a composite lithium negative electrode material containing a lithium-copper alloy skeleton network and copper foam. After further removal of m...

Embodiment 3

[0046] A preferred embodiment of the present invention provides a method for preparing a foamed carbon three-dimensional porous material containing a lithium alloy skeleton network and its composite lithium negative electrode material. The specific steps are as follows:

[0047] Metal aluminum and metal lithium are placed in a crucible with a molar ratio of 1:30, and the temperature is raised to 600°C under an argon atmosphere to make the metal mixture into a molten state, and a molten lithium-rich lithium aluminum alloy is obtained. Then, the carbon foam is placed on the molten lithium-rich lithium aluminum alloy, and the molten alloy is hot poured into the structure of the carbon foam, and the filling thickness accounts for 5 / 4 of the thickness of the entire substrate. Finally, it was cooled to room temperature within 100s to obtain a composite lithium negative electrode material containing lithium aluminum alloy skeleton network and foamed carbon. After further removal of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com