A kind of enzyme-modified anticoagulant valve and its preparation method

An anti-coagulation and modification technology, applied in the field of biomedical engineering functional materials, can solve the problems of difficult long-term storage and high price, achieve the effects of easy preparation, reduce valve failure rate, and avoid unstable donor sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

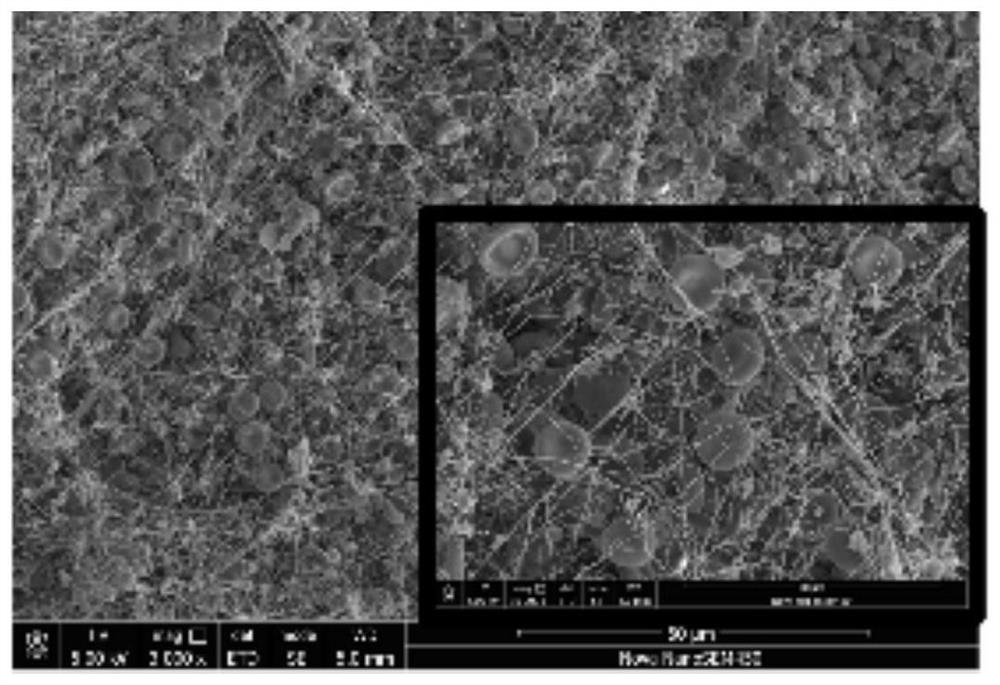

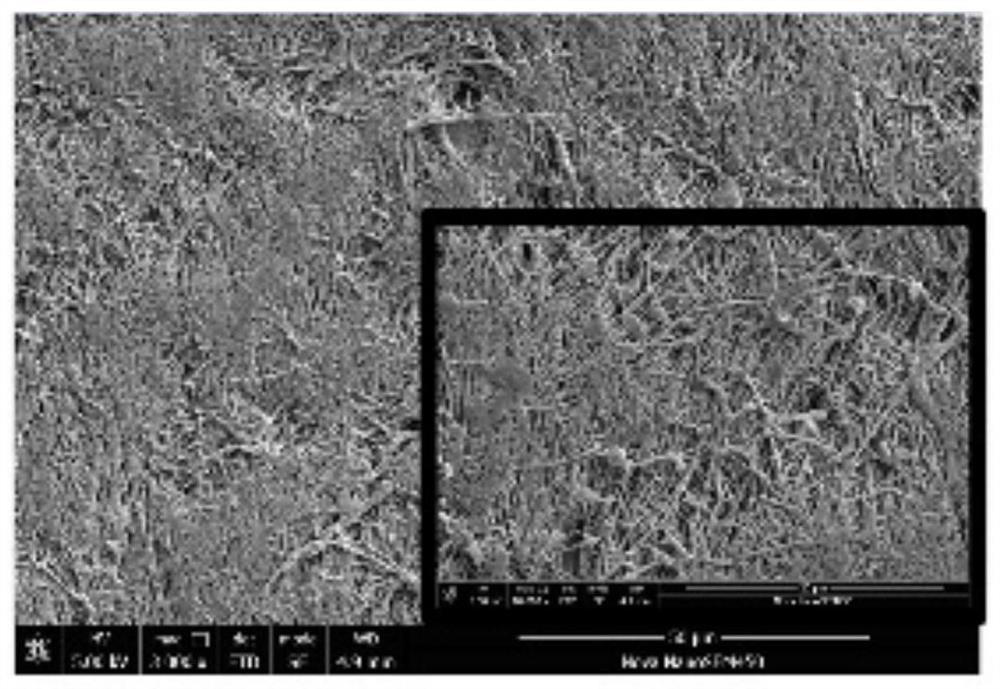

Image

Examples

Embodiment 1

[0027] A preparation method of an enzyme-modified anticoagulant valve, comprising the following steps:

[0028] (1) Put the valve into a mixed aqueous solution of dopamine with a concentration of 1 mg / ml and ferric chloride with a concentration of 0.5 mg / ml, react at 25°C for 20 minutes, take out the valve and wash it 3 times, and complete a reaction cycle;

[0029] (2) Repeat the reaction cycle 10 times and dry;

[0030] (3) Soak the material treated in step (2) in a glutaraldehyde solution with a concentration of 0.5% and activate it for 4 hours and then wash it;

[0031] (4) Put the material obtained in step (3) into a PBS solution of glucose oxidase at a concentration of 0.15 mg / ml, activate at 4° C. for 4 hours, and wash to obtain the target material.

Embodiment 2

[0033] A preparation method of an enzyme-modified anticoagulant valve, comprising the following steps:

[0034] (1) Put the valve into a mixed aqueous solution of tannic acid with a concentration of 1 mg / ml and ferric chloride with a concentration of 0.1 mg / ml, react at 30°C for 10 minutes, take out the valve and wash it 3 times, and complete a reaction cycle;

[0035] (2) Repeat the reaction cycle 5 times and dry;

[0036] (3) Soak the material treated in step (2) in a glutaraldehyde solution with a concentration of 0.15% and activate it for 2 hours before washing;

[0037] (4) Put the material obtained in step (3) into a PBS solution of glucose oxidase at a concentration of 0.2 mg / ml, activate at 4° C. for 4 hours, and wash to obtain the target material.

Embodiment 3

[0039] A preparation method of an enzyme-modified anticoagulant valve, comprising the following steps:

[0040] (1) Put the valve into a mixed aqueous solution of tannic acid with a concentration of 1 mg / ml and copper chloride with a concentration of 0.1 mg / ml, react at 30°C for 20 minutes, take out the valve and wash it 3 times, and complete a reaction cycle;

[0041] (2) Repeat the reaction cycle 5 times and dry;

[0042] (3) Soak the material treated in step (2) in a glutaraldehyde solution with a concentration of 0.2% and activate it for 2 hours before washing;

[0043] (4) Put the material obtained in step (3) into a PBS solution of glucose oxidase at a concentration of 0.2 mg / ml, activate at 4° C. for 4 hours, and wash to obtain the target material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com